Application Of 3D Printing Tantalum Powder In Biomedicine

Additive manufacturing attracted public attention approximately six or seven years ago as a new production method for the global manufacturing industry. The term "3D printing" was introduced.

The 3D printing of metals is used in various industrial applications. The process utilises digital simulation-based rapid prototyping. Metal, ceramic and plastic powders are applied in a layer-by-layer method. It is employed to produce plastic models and precision components. In certain cases, a complete car may be produced using this technique.

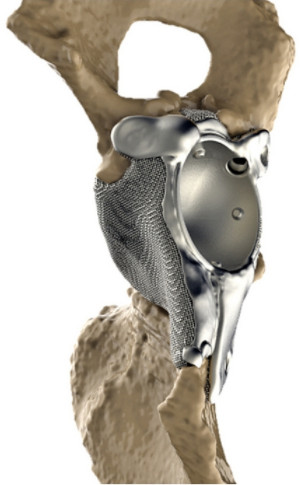

In biomedicine, 3D printing technology is used to produce artificial bones. Tantalum powder is a biocompatible material. It demonstrates high biological inertia and resistance to corrosion. This article examines the application of 3D printing using tantalum powder in biomedicine, for instance for hip joints.

Metalysis has produced a biologically inert tantalum lattice structure. The structure yields variable outcomes. It is engineered to match the mechanical stiffness of human bone. The lattice integrates with bone cells, thereby enabling tissue ingrowth. Stanford Materials provides ultrafine tantalum powder (D50=3 µm, D90<10 µm) for biological applications. When used in additive manufacturing and selective laser melting, this ultrafine tantalum powder maintains its structural integrity. The final surface may be further modified. The metallic properties remain stable.

Tantalum powder is applied in the biological sector, especially in medicine. Metal 3D printing for hip joint replacement has been documented. By scanning the hip, customised metal replacements are manufactured using 3D printing. This method allows patients to receive bespoke hip joints. Previously, only standard sizes were available. In addition to hip joint implants, supportive lumbar cages for the spinal column are of interest to the industry.

Conclusion

We thank you for reading this article. We hope it has contributed to a better understanding of the application of 3D printing tantalum powder in biomedicine. If you wish to learn more about Ti products, please visit Stanford Advanced Materials (SAM) for further information.

Stanford Advanced Materials (SAM) is a global supplier of tantalum powder. It has over twenty years of experience in producing and distributing tantalum products. Its products satisfy the research, development and manufacturing requirements of its clients. SAM is expected to fulfil the role of a supplier and business partner for tantalum.

Also read: Spherical Tantalum Powder for 3D Printing

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento