The Application Of Zirconium Products

What is Zirconium?

Zirconium, with the chemical symbol Zr and atomic number 40, has a melting point of 1 852°C. It belongs to the group of metals with high melting points. It absorbs oxygen from the air and forms an oxide film that exhibits a silver-white colour.

What applications exist for zirconium compounds?

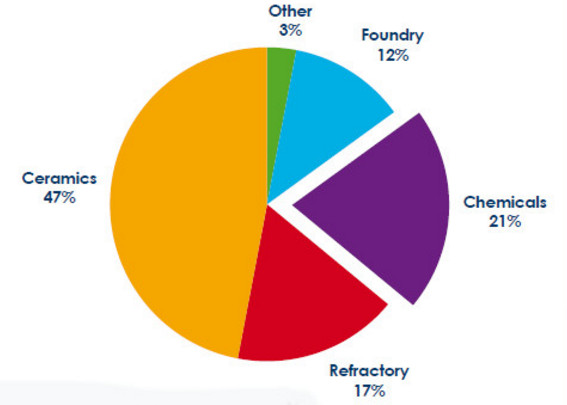

Zirconium compounds are principally used in industrial production in the forms of zirconium silicate, zirconium carbonate, zirconium oxychloride and zirconium dioxide. The principal component of zircon sand is zirconium silicate. Following grinding, sintering and powdering, zircon sand is processed into a ceramic glaze. This glaze exhibits chemical stability and remains unaffected by the ceramic sintering atmosphere; consequently, it improves the hardness of the ceramic body. It is frequently applied in construction ceramics, sanitary ceramics and the general pottery industry.

Zirconium carbonate is an important raw material for the textile and paper industries. It is used as a surface aid during paper production. In addition, it is employed as an additive and impregnation agent in the cosmetics sector.

Zirconium oxychloride is utilised in the production of rubber additives, metal surface treatment agents and paint driers. Zirconium dioxide and composite zirconium dioxide ceramics can withstand high temperatures and maintain stability. They do not react with alkaline or most acidic solutions and are suitable for manufacturing ceramic crucibles and other precision ceramics.

What applications exist for pure zirconium metal?

Pure zirconium metal is categorised by industrial, firearms and nuclear quality. In practice, it is mainly available as zirconium sponge. Industrial zirconium metal is primarily used for the manufacture of corrosion-resistant equipment such as pumps, heat exchangers, valve pipes and nozzles. Zirconium wire is used in the production of grid plate supports and cathode holders.

Zirconium performs deoxidation, denitrification and desulphurisation. It is added to metal alloys to increase hardness and strength. For instance, armour steel for armoured vehicles and tanks typically includes zirconium. In the case of high-voltage wires, copper wire containing zirconium is preferred given that it increases the melting point without compromising conductivity.

Firearm-capable zirconium sponge powder

Firearm-capable zirconium sponge powder is highly inflammable and is primarily used for the manufacture of fire-triggering materials, flash powder and military propellants. Zirconium of nuclear quality is produced to a higher purity level. It is an important strategic military metal, used in the manufacture of structural materials and components for aircraft carriers, submarines and power generation reactors.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento