The Functional Pigments Commonly Found In Coatings

It is established that the primary function of pigments is to impart colour. However, pigments also perform additional roles beyond mere colouring.

Pearlescent Pigment

Owing to properties such as high gloss, adequate decorative performance, non-toxicity, lightfastness, weather resistance, acid resistance, alkali resistance, heat resistance, good dispersion and non-conductivity as well as non-magnetism, this pigment is used in automotive coatings, motorcycle coatings, bicycle coatings, toys and decorative coatings. It is applied in a thin film that has a high refractive index and produces a pearlescent appearance by light interference. Its colour is determined by its optical characteristics. Consequently, various chemical formulations exist that yield a similar pearlescent effect.

Natural pearlescent pigments are extracted from pearls and fish scales. Early synthetic variants incorporated Hg2Cl2, PbHPO4 or lead–HASO4 compounds; these substances exhibited toxicity. Later, alkaline lead carbonate pearlescent pigments were introduced. In the early 1960s, bismuth oxychloride (BiOCl) pigments with low toxicity were discovered. Currently, pearlescent pigments are mainly manufactured as mica–titanium pigments. Mica, quartz, aluminium oxide or glass flake powders serve as the base material. A transparent metal oxide layer with a high refractive index is coated on the surface. When light strikes the flat surface, reflected and refracted beams interfere to produce a measurable three-dimensional pearlescent colour.

Fluorescent Pigment

Organic fluorescent pigments are also called sunfluorescent pigments. They absorb visible and ultraviolet light and convert the ultraviolet component, previously undetectable by the human eye, into visible light of a specified colour. Their overall reflectance exceeds that of conventional colour pigments. Fluorescent pigments are classified into two categories: fluorescent pigments and fluorescent resin pigments. They are used in secure passageways, security doors, fire extinguishers, road signs and in advertising, buildings and decorative coatings.

Inorganic fluorescent pigments consist mainly of zinc sulphide (ZnS) and cadmium sulphide (CdS). They include trace metallic compounds such as Cu, Ag and Mn that act as activators. Depending on the activator, these pigments emit green, red, blue and yellow light. In sunlight, inorganic fluorescent pigments appear colourless or are only lightly coloured, and some varieties display colour solely under ultraviolet light.

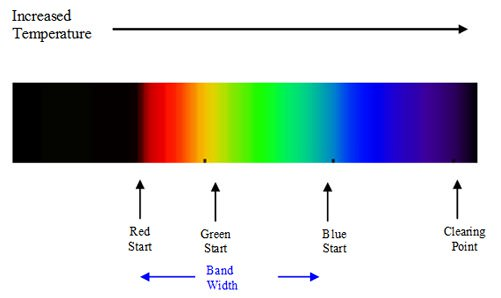

Temperature-Indicating Pigment

Temperature-indicating pigments are also known as colour-changing pigments. When a decolourisation pigment is applied as a topcoat at locations where temperature variation is difficult to measure, temperature changes can be determined by observing a change in the coating colour. These pigments are divided into two types. One type consists of reversible decolourisation pigments, which change colour when the temperature increases and revert to their original colour upon cooling. The other type comprises irreversible pigments, which undergo permanent chemical changes upon heating and do not return to their original colour when cooled.

Common irreversible colour pigments include sulphates, nitrates, phosphates, chromates, sulphides, oxides, azo pigments, phthalocyanine pigments and arylmethane dyes of metals such as lead, nickel, cobalt, iron, strontium, zinc, manganese, molybdenum, barium and magnesium. Reversible pigments mainly consist of compounds based on Ag, Hg and Cu iodides, complex or complex-salt cobalt compounds, nickel salts and hexamethylenetetramine compounds.

Metallic Pigment

Metallic pigments represent a distinct category with an extensive history. Industrial development has increased the demand for various powders. The most common metal powders are aluminium powder, zinc powder and lead powder. Alloy forms such as copper–zinc powder (commonly known as gold powder), zinc–aluminium powder and stainless steel powder are also produced.

Metallic pigments possess distinctive properties. As powders, they consist of metals or alloys that display a bright metallic gloss and inherent colour. Many metallic pigments are used for decorative purposes. Examples include copper–zinc powder and aluminium powder.

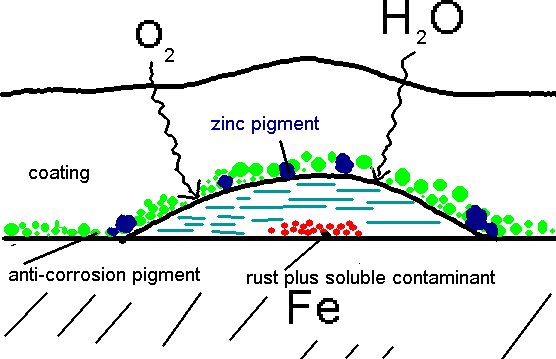

Corrosion Protection Pigment

Corrosion protection pigments do not serve a colouring function. They are employed to create coatings that protect metal surfaces from corrosion. Rust protection agents such as Mennige powder, red iron powder, iron–titanium composite powder and aluminium–zinc tripolyphosphate powder are classified as rust protection pigments.

Traditional coatings utilise corrosion protection pigments that primarily contain chromium, lead and cadmium compounds such as Mennige, lead powder and chromates of zinc, barium and lead. Coatings produced with these pigments function to protect against corrosion but are toxic. Their manufacture and application can result in environmental pollution and health hazards. Consequently, many countries have imposed strict bans on these substances. Current research focuses on the development of environmentally friendly and non-toxic corrosion protection coatings. Researchers have produced phosphate, molybdate, borate and flake pigments as well as other non-toxic, effective rust protection pigments.

Antifouling Paint

Marine areas worldwide record more than 18 000 species of attached animals and 600 species of attached plants. The attachment of marine organisms to a ship’s hull increases drag and fuel consumption, reduces speed and elevates mechanical wear. In addition, micro-organism adhesion on steel structures causes microbiologically induced corrosion and damages the metallic coating, thereby accelerating metal corrosion and ageing. Consequently, the lifespan of steel structures and components in ships is notably reduced, leading to frequent dry-docking for maintenance, which consumes significant time and resources.

Antifouling paint accounts for approximately 50 % of the material expenditure for ship coatings. It is a specialised coating applied to the ship hull and underwater installations. Typically, the coating is applied as the outermost layer on the hull. Its primary function is to release toxic substances gradually through exudation, diffusion or hydrolysis, thereby preventing the settlement of marine organisms on the ship’s hull or underwater structures.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento