The Performance And Application Of Hafnium

Hafnium, chemical symbol Hf, atomic number 72, has a melting point of 2 233℃. It is a rare metal with a high melting point. In air, elemental Hafnium forms an oxide layer that provides substantial corrosion resistance and stable chemical properties. Hafnium metal powder is highly reactive and inflammable in air.

Hafnium and Zirconium exhibit a close association. No pure Hafnium mineral is found in nature. Zirconium minerals generally contain 1 % to 2 % Hafnium; some contain 5 % Hafnium. The extraction and processing of Hafnium is extremely complex. It is primarily sourced from Australia, South Africa, the United States, Brazil, India and other regions. Zircon sand serves as the raw material. Following extraction and separation, Hafnium oxide is obtained. Thereafter, chlorination, purification and reduction of Hafnium tetrachloride yield Hafnium sponge. Since Hafnium sponge is not malleable, it must be iodised and melted to form a Hafnium ingot. Subsequent forging, sandblasting, pickling and cold rolling produce strips, bars and other forms. Melting with other metals results in the formation of various Hafnium alloys.

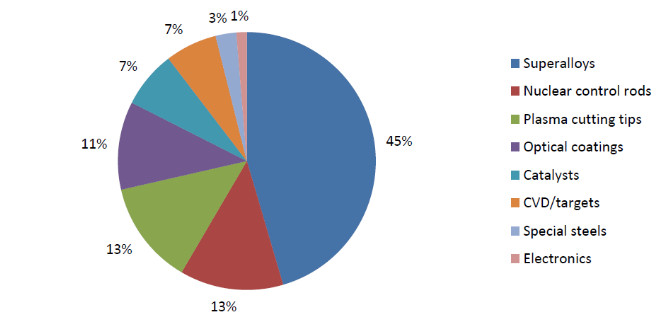

Owing to its favourable nuclear properties, Hafnium is widely utilised within the nuclear industry. It exhibits acceptable welding and machining characteristics, as well as high temperature and corrosion resistance. As a neutron absorber, it captures a wide range of thermal neutrons and is employed in the manufacture of control rods and protective devices for nuclear reactions. Additionally, Hafnium can emit electrons. It is used as a cathode in an X-ray tube and is a standard electronic material in the photovoltaic industry. Hafnium also functions as an alloying element offering high ductility, oxidation resistance and elevated temperature capacity. Niobium-Hafnium alloys containing approximately 10 % Hafnium are used in the aerospace industry. A Tantalum-Tungsten alloy with roughly 2 % Hafnium demonstrates high creep resistance and can be applied as a protective coating for spacecraft.

Further information: 4 Uses of Hafnium | The Applications of Hafnium and Hafnium Alloys

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento