The Power Of Sound: Exploring Ultrasonic Cleaners In Industrial Applications

Short guide:

2 Introduction to the Ultrasonic Cleaning Machine

3 Applications of Ultrasonic Cleaners

4 Case Studies: Specific Industrial Applications of Ultrasonic Cleaning Machines

1 Introduction

Ultrasonic waves are mechanical waves with extremely short wavelengths. They are termed ultrasonic because the lower limit of their frequency range exceeds that of human hearing. Owing to the cavitation effect, ultrasonic waves cause the formation of microscopic bubbles in a liquid. These bubbles expand rapidly and subsequently collapse, which creates high pressure. This action can break down firmly adherent deposits. Consequently, ultrasonic cleaners are used in many cleaning processes. Ultrasonic cleaners are applied in daily use, scientific research and industrial production due to their effective cleaning performance. This article explains the working principles of ultrasonic cleaning machines and discusses industrial applications, thereby providing a reference for potential purchases.

2 Introduction to the Ultrasonic Cleaning Machine

2.1 The Nature of Ultrasound and the Working Principle of the Ultrasonic Cleaner

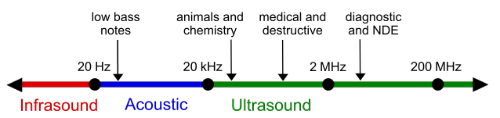

In air, ultrasonic waves have wavelengths below 2 cm and frequencies above 20 kHz. These wavelengths fall below the typical lower limit of human hearing (2 cm), therefore they are classified as ultrasonic.

In any medium, ultrasound obeys the same laws of reflection, refraction, diffraction and scattering as infrasound and audible sound waves. However, since ultrasonic wavelengths are very short, typically a few centimetres or even thousandths of a millimetre, their ability to penetrate obstacles is limited. Given that obstacles are often much larger than the wavelengths, scattering occurs significantly. In accordance with Rayleigh’s scattering law, the intensity of scattered waves is inversely proportional to the fourth power of the wavelength.

Fig. 1 Frequency Range of Ultrasound

Ultrasonic waves display several characteristics. They travel in straight lines in a homogeneous medium and are difficult to diffract. Shorter wavelengths further reduce diffraction. Consequently, scattering increases and penetration decreases.

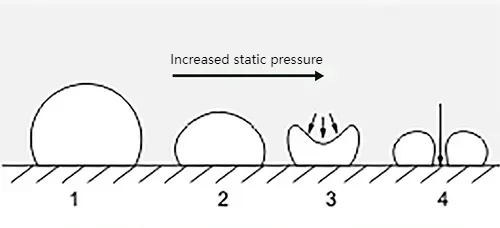

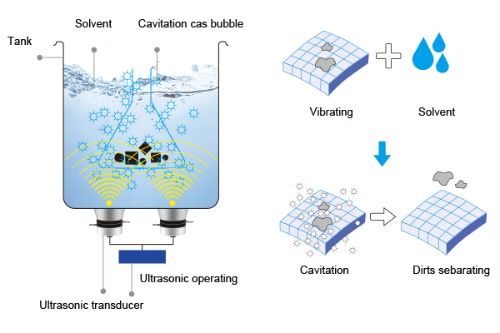

Cavitation – As ultrasonic waves propagate in a medium, they create alternating high-pressure and low-pressure cycles. In the compression phase, the molecules in the medium are forced closer together. In the rarefaction phase, the molecules are spread apart. When the pressure is sufficiently low, the spacing between molecules exceeds what is necessary for stability, and microbubbles form. These microbubbles rapidly expand and collapse, resulting in pressure pulses that may exceed several thousand atmospheres. The resulting microjet impact aids in detaching contaminants from surfaces. This cavitation mechanism underpins the cleaning action of ultrasonic machines.

Fig. 2 Cavitation

2.2 Structure of the Ultrasonic Cleaning Machine

1. Ultrasonic Generator

The ultrasonic generator supplies high-frequency electrical energy. It converts alternating current into high-frequency electrical energy, typically between 20 kHz and 40 kHz, and transmits it to the ultrasonic transducer.

2. Ultrasonic Transducer

Ultrasonic transducers usually consist of piezoelectric materials, for example piezoelectric ceramic. They therefore are also known as piezoelectric transducers. The device contains a power transformer, rectifier system, oscillator, driver, amplifier and output transformer. It converts the high-frequency electrical energy from the generator into mechanical vibrations. The transducer is fixed to the bottom or side of the cleaning tank, where it transforms the energy into high-frequency vibrations.

3. Cleaning Tank

The cleaning tank holds the cleaning solution and the items to be cleaned. It is usually made of stainless steel and other corrosion-resistant materials to prevent damage from cleaning fluids and deposits on the tank. In some models, heating and temperature control devices are installed to maintain the cleaning solution’s temperature. The dimensions and shape of the tank may be adapted to suit different cleaning requirements.

4. Vibration Plate

The vibration plate is typically secured to the bottom or side of the cleaning tank and linked to the ultrasonic transducer. It distributes the mechanical vibrations evenly throughout the cleaning solution, thus facilitating the cavitation effect.

5. Cleaning Fluid

The cleaning fluid, usually a mixture of water and a suitable detergent, acts as the medium in which cleaning occurs. The choice of cleaning fluid depends on the material being cleaned and the type of contamination. The appropriate fluid can improve the cleaning efficiency.

6. Control Panel

The control panel regulates key parameters such as ultrasonic frequency, power, cleaning duration and temperature. Modern devices feature digital displays and programming functions, so that users may control the cleaning process accurately. The panel includes a socket and a fuse on the reverse side. The power supply also incorporates an overcurrent protection circuit for safe operation.

7. Heating System (optional)

Some ultrasonic cleaning machines include a heating system for the cleaning fluid. Heating increases the temperature of the solution, which improves its ability to break down oily contaminants.

8. Filtration System (optional)

A filtration system removes deposits and particles from the cleaning fluid. This measure helps maintain the fluid’s cleanliness and prolongs its effective use.

9. Draining System

The draining system allows the cleaning fluid to be removed from the tank. It typically consists of a drain valve and associated piping, facilitating both fluid exchange and cleaning of the tank.

Fig. 3 Structure and Working Principle of the Ultrasonic Cleaning Machine

3 Applications of Ultrasonic Cleaners

3.1 Industrial Applications

Ultrasonic cleaning machines are used across various industrial sectors.

l In manufacturing, ultrasonic cleaning is deployed to remove small deposits from product surfaces completely.

l In the electronics industry, ultrasonic cleaners are primarily used for cleaning electronic components and printed circuit boards. During production, components often accumulate microscopic dust and residues. Ultrasonic cleaning removes these particles to maintain component cleanliness and quality.

l In automotive manufacturing, many parts such as engine and transmission components, and fuel injection systems require high levels of cleanliness. Ultrasonic cleaning removes oil, metal shavings and other contaminants to improve assembly quality and overall performance.

l In precision engineering, parts require very high cleanliness standards. Ultrasonic cleaners remove fine particles from both the surface and internal structures to ensure dimensional accuracy and proper functioning.

l In the production of optical lenses and instruments, ultrasonic cleaning removes dust and fingerprints from lenses to maintain clarity and precision.

l In steel production, surfaces often have oxide layers, grease and other residues. Ultrasonic cleaning quickly eliminates these contaminants, thereby improving steel surface quality.

In scenarios that require high precision and cleanliness, ultrasonic cleaners meet stringent cleaning requirements. For example, in the medical industry, ultrasonic cleaners are used to decontaminate surgical instruments and other regulatory equipment. In pharmaceutical production, devices such as reactors and stirrers are cleaned to support safe and environmentally compliant processes.

l In food processing equipment, ultrasonic cleaning removes residual food particles and deposits, thus ensuring hygiene and food safety.

l In the aerospace industry, parts require extremely high cleanliness. Ultrasonic cleaners clean complex shapes and structures in aircraft components, thereby supporting reliable performance in harsh environments.

l Ultrasonic cleaners are also applied in the watch industry, jewellery processing, chemical laboratories and other sectors.

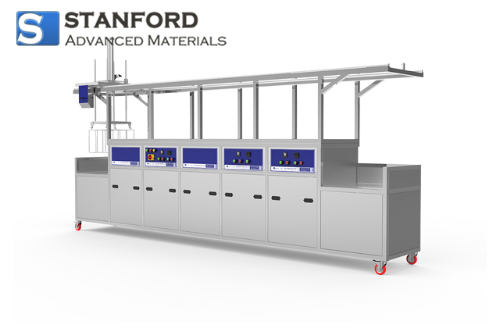

In manufacturing, the use of ultrasonic cleaning machines increases productivity and product quality. The technology can penetrate narrow gaps and intricate structures, achieving higher levels of cleanliness with minimal risk to precision components. For instance, machines that use water-based cleaning fluids reduce the need for chemical agents, thereby lowering environmental discharge. Stanford Advanced Materials (SAM) offers a range of ultrasonic cleaning systems designed for large-scale industrial applications, tailored to industry size, spatial requirements and efficiency targets. Fig. 4 illustrates a five-tank ultrasonic cleaner fitted with a semi-automated transfer system.

Fig. 4 Five-Tank Ultrasonic Cleaner with Semi-Automated Transfer System

3.2 Life Applications

Ultrasonic cleaners are used outside the industrial sector and have many practical applications in everyday life. The cavitation effect enables efficient cleaning of various items while saving time and manual effort.

l Ultrasonic cleaning machines remove dirt and grease from jewellery, watches and other accessories, often regaining the item’s original appearance. They also access narrow gaps where manual cleaning is difficult.

l Eyeglasses and frames are cleaned thoroughly using ultrasonic devices to avoid surface scratches or damage.

l Kitchenware, particularly items with complex forms such as cutlery and sieves, benefit from ultrasonic cleaning to remove stubborn food residues.

l Dental devices used at home, such as toothbrush heads, dentures and braces, are prone to bacterial deposits. Ultrasonic cleaners help maintain proper oral hygiene.

l Physiotherapy equipment, including massage heads, cupping devices and electrode pads, can be cleaned ultrasonically to remove post-use residues and ensure hygienic conditions.

l Cosmetic tools such as shavers, hair cutting scissors, make-up brushes and manicure instruments benefit from ultrasonic cleaning, which reduces the risk of skin infections.

l Makeup compacts including eyeshadow palettes, powder cases and lipstick holders may be cleaned ultrasonically to remove cosmetic residues and maintain container cleanliness.

l Ultrasonic cleaners can also be used to clean collections of artefacts to preserve their original appearance and maintain their value.

In life applications, the key benefit of ultrasonic cleaning is the reduced need for strong chemical cleaners. This improves safety and decreases environmental contamination.

Fig. 5 An Ultrasonic Eyewear Cleaning Machine

3.3 Applications in Scientific Research

Ultrasonic cleaners are applied in scientific research for cleaning laboratory glassware, plasticware and metal tools. Their high cleaning efficiency, accuracy and non-destructive cleaning properties assist in experimental procedures.

l Laboratory glassware, plastic equipment and metal tools require a high degree of cleanliness so that experimental results are not compromised. Ultrasonic cleaners remove adhering residues, chemicals and particles effectively.

l In materials science and biological research, surface contaminants must be removed during sample preparation. Ultrasonic cleaning is used to prepare samples and ensure accurate experimental outcomes.

l For chemical analysis experiments, efficient cleaning of sample vessels, reactors and other equipment is required so that residues do not affect the results.

l In metallurgy and material research, ultrasonic cleaning removes grease, oxides and other contaminants from metal surfaces. This ensures that samples remain clean for accurate measurements.

l Electronic components used in research, such as microelectronic chips, sensors and printed circuit boards, must be free of contaminants. Ultrasonic cleaning eliminates microscopic particles from these surfaces.

l Optical experiments require lenses, prisms, optical fibres and other components to be cleaned thoroughly. Ultrasonic cleaning removes dust and fingerprints to maintain the accuracy of optical measurements.

l During the preparation and processing of nanomaterials, non-reactive substances must be removed from surfaces. Ultrasonic cleaners effectively access microstructures and remove contaminants completely.

l In biological and medical research, cleaning of cell culture equipment and slides is essential. Ultrasonic cleaning removes residues from biological samples. Microfluidic chips are also cleaned ultrasonically to maintain their function.

The application of ultrasonic cleaners in research enables the controlled cleaning of complex objects in a short span of time, without damaging sensitive instruments or samples. The use of automated machine control reduces operator error and increases experimental efficiency. In addition, the reliance on water-based cleaning fluids helps reduce the use of strong chemical agents, thereby minimising environmental impact.

Fig. 6 Laboratory Ultrasonic Cleaner for Instrument Cleaning

4 Case Studies: Specific Industrial Applications of Ultrasonic Cleaning Machines

The following case studies describe the use of ultrasonic cleaning in industrial manufacturing.

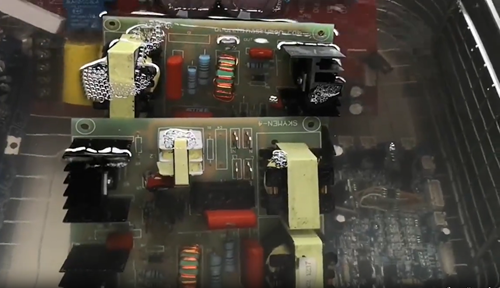

4.1 Improvement of Printed Circuit Board Maintenance with Ultrasonic Cleaning in the Electronics Industry

Printed circuit boards (PCBs) are vital components of electronic devices. They provide mechanical support and electrical connections for components via printed conductive pathways on an insulating substrate. Flux used in soldering PCB components is categorised into water-soluble, colophony-based and no-clean types. The first two types frequently require ultrasonic cleaning, even though manual brushing with alcohol is also common. Even with no-clean flux, manufacturers often utilise ultrasonic cleaning. In high-density PCB designs, dust and residues may accumulate between closely spaced connections. Such accumulation can cause short circuits under moist conditions, though these issues may resolve upon drying. Thus, most electronic manufacturers employ ultrasonic cleaning as a standard process.

Fig. 7 Ultrasonic Cleaning Machine for PCB Cleaning

4.2 Enhancing Cleaning Efficiency in the Hardware Sector Using Ultrasonic Technology

Compared with other cleaning methods such as immersion, brushing, pressure washing, vibratory cleaning and steam cleaning, ultrasonic cleaning machines are used predominantly in production groups. Companies in certain hardware sectors have gradually adopted ultrasonic cleaning to replace traditional methods. Ultrasonic machines produce high cleaning efficiency by utilising sound wave propagation through a medium, which results in increased penetration and effective cavitation. This method is applied to cleaning parts and components with complex geometries, inner cavities and fine holes. Components cleaned include automotive wheel hubs, coated parts, vacuum-deposited parts, engine parts, bearings, die-cast parts, stamped parts, eyewear, stainless steel tableware, compressors, watch components, precision textile devices, precision moulds, gears, crankshafts and other precision elements. These precision items are cleaned during production to remove oil, wax and deposits. This technology is also extensively used to clean electronic circuit boards, bearing parts, optical lenses, automotive parts, vacuum ion coating components, hardware coating parts, audio magnetic heads, precision hardware parts, medical devices, liquid crystal displays and aerospace parts. Its application is essential for specific cleaning tasks across industries.

4.3 Improvement of Pre- and Post-Treatment Processes in the Electroplating Industry with Ultrasonic Cleaning

In the electroplating industry, ultrasonic cleaning is used to process various components, including plated parts, vacuum-plated parts, locks, motor parts, bearings, die-cast parts, stamped parts, watch cases and bands, eyewear frames, stainless steel tableware, compressors, precision textile devices, precision moulds, gears, crankshafts, valves, radiators and other precision metal parts. The method removes oil, wax and deposits from all types of metal parts during manufacturing. In electroplating, ultrasonic cleaning is divided into pre-treatment for removing polishing wax, machining oils and contaminants; and post-treatment for eliminating residual coating solutions and process residues.

5 Conclusion

Ultrasonic cleaning technology has proven useful in industrial, domestic and scientific applications due to its efficient, thorough and gentle cleaning action. The technique utilises cavitation induced by ultrasonic waves to remove dirt, grease and contaminants from surfaces and internal structures without damaging the objects. This feature is particularly suitable for cleaning items with complex shapes and minute crevices. In industrial production, ultrasonic cleaning machines improve production efficiency and product quality, reduce the use of chemical cleaning agents and lower environmental emissions. In everyday life, they offer a safe, environmentally friendly and efficient cleaning solution. In scientific research, the technology meets the stringent cleanliness requirements of experimental equipment and samples, thus supporting precise scientific measurements. Overall, the ultrasonic cleaning machine is an advanced cleaning tool that merits further promotion and use, whether for improving cleaning efficiency, ensuring the performance of products and devices or for environmental and safety considerations.

References:

[1] Manufacture and performance tests of an ultrasonic cleaning system for solar wafer cells [J]. Journal of the Korean Society of Manufacturing Technology Engineers, 2019, 28(4).

[2] Escrig J, Woolley E, Rangappa S, et al. Clean-in-place monitoring of different food fouling materials using ultrasonic measurements [J]. Food Control, 2019, 104.

[3] M S K. Research: Ensuring cavitation in an ultrasonic cleaner for medical devices [J]. Biomedical Instrumentation & Technology, 2019, 53(4).

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento