Titanium Alloy Forging Process

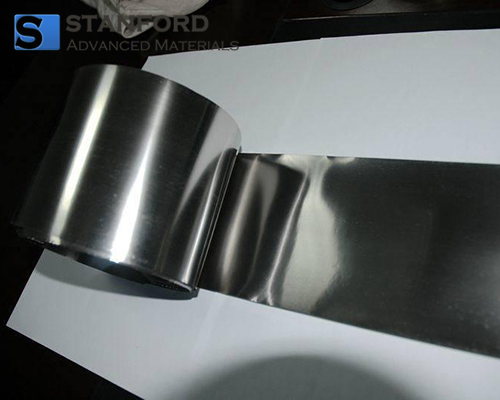

Titan and Titanlegierungen exhibit a low density, a high specific strength and good corrosion resistance. They are extensively used in various sectors. Researchers have examined the forging of titanium alloys in detail in order to improve their utilisation.

Procedure for Forging Titanium Alloys

The Main Process of Forging Titanium Alloys

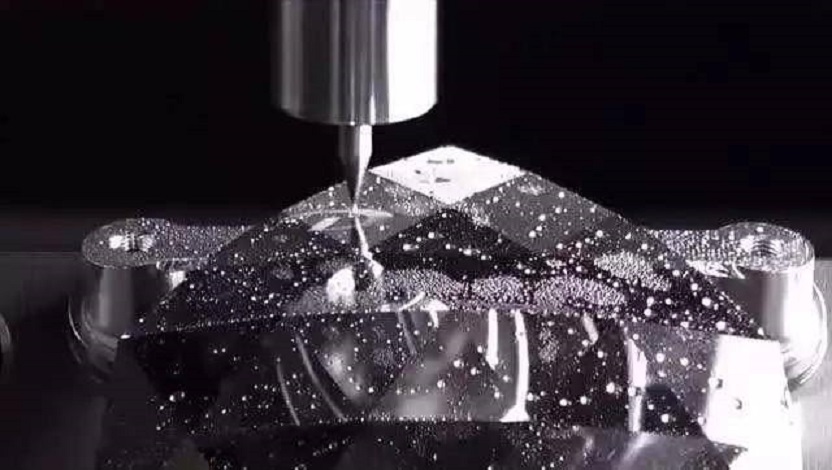

Forging is a plastic deformation process that employs the material’s ductility to impose a predetermined shape and structural characteristics onto the workpiece under the pressure of a tool.

1. Open-Die Forging

In open‐die forging the workpiece is deformed between two flat dies that lack a cavity. The tools used are simple in design, flexible, have short production cycles and are cost efficient. However, this method is labour intensive, difficult to manage, and yields lower forging quality while requiring considerable machining allowance. Consequently, it is only suitable when specific performance criteria of the component are not demanding and production volumes are low.

2. Closed-Die Forging

In closed-die forging the workpiece is deformed between two dies with preformed cavities. The forging is enclosed within the cavity, and excess metal is displaced through the narrow gap between the dies, forming flash around the component. Given that the metal is forced into the cavity under the resistance of both the die and the flash, controlled material flow is achieved.

3. Die Forging

In die forging the process is configured so that no lateral flash forms in a direction perpendicular to the die movement. The cavity in a closed die serves two functions: shaping the workpiece and providing guidance during the process.

4. Flow Press Forging

This method refers to the application of an extrusion process within die forging. It comprises both forward extrusion forging and backward extrusion forging. This approach allows for the production of both hollow and solid components that meet high geometrical precision requirements and possess dense internal structures.

5. Multidirectional Die Forging

In multidirectional die forging, a striker applies alternating and simultaneous vertical and horizontal forces on the workpiece. One or more perforation punches ensure that the metal is displaced from the centre of the cavity outwards, thereby filling the cavity completely.

6. Partial Die Forging

To manufacture large integral forgings using available hydraulic presses with moderate tonnage capacity, partial die forging methods – such as segmented forging – may be employed. This method processes the forging in sections so that the required press tonnage remains low. It may be applied to particularly large forgings using medium hydraulic presses.

7. Isothermal Forging

Prior to forging the dies are preheated to the workpiece’s forging temperature, and the temperature of both the dies and the workpiece remains constant during the entire process. Under these conditions, a large deformation may be achieved with a relatively low deformation force.

Forging of titanium alloys is widely practised in the aerospace industry – for instance, isothermal die forging has been used in the manufacture of engine components and airframe parts. Additionally, industries such as automotive, energy and shipbuilding are increasingly adopting these forging processes.

Conclusion

We appreciate your attention to this article and hope that it has enhanced your understanding of the forging of titanium alloys. For further information on Titan and titanium alloys, please visit Stanford Advanced Materials (SAM).

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento