What Are The Applications Of Tungsten?

Tungsten is a metal with properties similar to steel. It exhibits a melting point of 3 422 °C, high hardness, excellent corrosion resistance and good electrical and thermal conductivity. It is utilised in scientific research, industrial manufacture, national defence and high-technology sectors. What are the specific applications of tungsten?

What are the applications of tungsten?

1. Application of Tungsten in Alloy Fields

Steel

Due to its high hardness and density, tungsten is a significant alloying element. It increases the strength, hardness and wear resistance of steel. It is used in the manufacture of various types of steel.

Common tungsten-containing steels include High-speed tool steel, Tungsten steel and tungsten-cobalt magnetic steel. They are used in the production of tools such as drill bits, milling cutters, dies and punches.

Carbide-Based Hardmetals

Tungsten carbide exhibits high wear resistance and refractory properties. Its hardness is near that of diamond. It is used in the manufacture of hardmetals.

Carbide-based hardmetals can be classified into four groups: tungsten carbide-cobalt; tungsten carbide-titanium carbide-cobalt; tungsten carbide-titanium carbide-tantalum carbide (niobium)-cobalt; and steel-bonded hardmetals. They are used in producing cutting tools, mining implements and wire drawing tools.

Wear-Resistant Alloys

Tungsten is a refractory metal with the highest melting point and high hardness. It is employed in the production of heat-resistant and wear-resistant alloys.

For example, alloys comprising tungsten, chromium, cobalt and carbon are used in the manufacture of wear-resistant components such as valves and turbine discs for aircraft engines. Alloys of tungsten with other refractory metals (such as tantalum, niobium, molybdenum and rhenium) are used in the production of rocket nozzles, engine components and other parts requiring high heat resistance.

High Specific Weight Alloys

Due to its high density and hardness, tungsten is ideal for producing high-density alloys. These alloys are classified according to composition and purpose into series such as W-Ni-Fe, W-Ni-Cu, W-Co, W-WC-Cu and W-Ag. They are used in the fabrication of armoured vehicles, heat sinks, switchgear and circuit breakers, given their high specific weight, strength, thermal conductivity, electrical conductivity and ease of processing.

2. Application of Tungsten in the Electronics Field

Tungsten exhibits considerable ductility, a low evaporation rate, a high melting point and strong electron emission. It is widely used in the electronics and power supply industries.

For example, Tungsten wires have high luminous efficacy and a long operational life. They are used in the production of filaments for incandescent lamps and iodine-tungsten lamps.

Furthermore, tungsten wire is used in the manufacture of direct-heating cathodes and grids in electronic oscillator tubes and cathode heaters in various electronic devices.

3. Application of Tungsten in the Chemical Industry

Tungsten compounds are employed in the production of certain types of dyes, pigments, inks, lubricants and catalysts.

For example, sodium tungstate is used in the manufacture of metallic tungsten, tungstic acid and tungstates, as well as in producing dyes, pigments, inks and electroplating solutions.

Tungstic acid is used as an etchant and dye in the textile industry and as a catalyst in the production of high-octane petrol. Tungsten disulfide is used in organic syntheses as a solid lubricant and catalyst in the production of synthetic petrol; bronze-coloured tungsten oxide is used in painting.

Tungsten Oxide

4. Application of Tungsten in the Medical Field

Due to its high hardness and density, tungsten alloys are suitable for medical applications such as X‑ray and radiation shielding. Standard medical products include X‑ray anodes, anti‑scatter plates, containers for radioactive substances and shielding cases for syringes.

5. Application of Tungsten in the Military Sector

Owing to its non‑toxic and environmentally friendly properties, tungsten has been used as a substitute for lead and depleted uranium in the manufacture of projectiles, thereby reducing environmental impact. It is also employed for its high hardness and heat resistance, which improves the performance of military products.

In military applications, products include tungsten alloy projectiles and kinetic energy penetrators.

Tungsten is also used in aerospace, navigation, nuclear energy, shipbuilding, the automotive industry and other sectors.

Conclusion

Thank you for reading this article. We hope it has provided a clearer understanding of the applications of tungsten. For further information on tungsten and Tungsten alloys, please visit Stanford Advanced Materials to obtain additional details.

Stanford Advanced Materials (SAM) is an international supplier of tungsten products. It has over two decades of experience in the manufacture and distribution of tungsten and tungsten alloys. The company offers tungsten products that meet customers' R&D and production requirements. We believe that SAM will be your chosen supplier and business partner for tungsten products.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

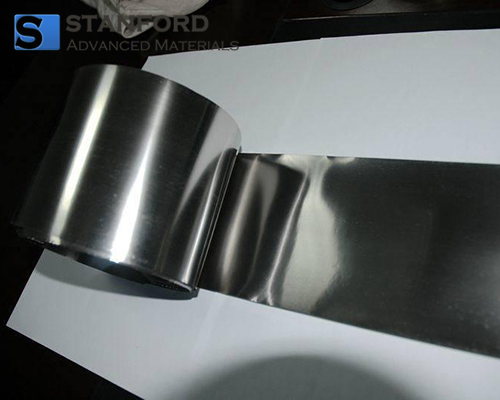

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento