What Are The New Ceramic Membrane Materials?

Ceramic membranes display unique advantages in many demanding applications because of their high resistance to temperature, pressure and corrosion. They have become one of the fastest evolving and promising categories in petrochemistry, food technology, medical sectors, environmental technology, energy and metallurgy.

Conventional ceramic membrane materials such as Aluminium Oxide, Zirconium Dioxide and Titanium Oxide limit further applications in modern industry. They incur high costs and only a few material types are available. Consequently, the development of new and cost-effective ceramic membrane materials is significant for the adoption and dissemination of ceramic membrane technology.

Current research on new ceramic membrane materials focuses primarily on two aspects. Synthetic ceramic membrane materials include silicon carbide, mullite, cordierite, graphene and ceramic fibres. Natural ceramic membrane materials comprise natural zeolite, fly ash and kaolin.

Synthetic Ceramic Membrane Materials

* Silicon Carbide

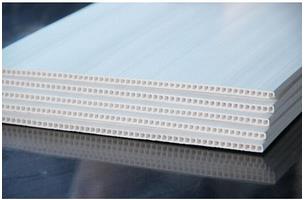

Silicon Carbide exhibits high strength, high thermal conductivity, resistance to corrosion, resistance to oxidation and a low cost. It maintains stable thermal and chemical properties under harsh conditions. Consequently, it represents a primary choice for developing ceramic membrane materials.

![]()

Manufacturing methods for ceramic silicon carbide membranes mainly include extrusion and slip casting. In comparison to conventional ceramic membrane materials, silicon carbide requires a lower sintering temperature and offers higher mechanical strength. It serves a broad range of applications in high-temperature and high-pressure systems.

* Mullite

Mullite is the only stable binary crystalline compound in the Al2O3-SiO2 system. It can be produced by thermal decomposition of aluminium silicate or by a high-temperature reaction between silicon dioxide and aluminium oxide. Mullite offers acid–base resistance, a low coefficient of thermal expansion and a high melting point. Consequently, it has received increasing attention. When compared to conventional ceramic film materials, the mullite ceramic membrane exhibits higher porosity and improved resistance to alkali.

* Cordierite

Cordierite has the theoretical chemical composition 2MgO-2Al2O3-5SiO2. It belongs to the hexagonal crystal system and comprises six-membered cyclic silicate crystals. It has a low coefficient of thermal expansion and a high decomposition temperature. It also offers low production costs and considerable performance. Consequently, it has received increased attention in the development of ceramic membrane materials. Compared to aluminium oxide ceramic membranes, cordierite ceramic membranes show better resistance to alkali corrosion, require a lower sintering temperature and incur lower manufacturing costs.

* Ceramic Fibres

Ceramic fibres combine high-temperature endurance, reliable chemical stability and long service life with the benefit of high porosity and a large specific surface area. During membrane manufacturing, ceramic fibres are randomly stacked based on their inherent form properties. This stacking produces an overall porosity that can exceed 70 %. The total porosity of the ceramic fibre membrane was almost twice that of the ceramic particle membrane. Consequently, the membrane flux increased and the permeability resistance decreased.

Some researchers used titanium dioxide nanofibres as raw material to fabricate double-layer TiO2 membranes on aluminium oxide supports by means of the dip-coating process. They added sols to the fibre layer to enhance adhesion between fibres. This measure reduced the formation of defect holes. At a sintering temperature of 480 ℃ and a pure water flux of 1 000 L/m²·h·bar, the molecular weight cut-off reached 32 000. The membrane performance exceeded that of conventional ceramic membranes.

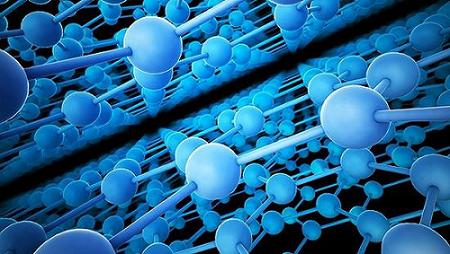

* Graphene

Graphene, also known as a monolayer graphite sheet, refers to a dense arrangement of carbon atoms in a honeycomb lattice. The carbon atoms are arranged in a two-dimensional structure that resembles a graphite monolayer. Graphene is the only two-dimensional atomic crystal currently identified. Its theoretical specific surface area reaches up to 2 600 m²/g. It exhibits high thermal conductivity and reliable mechanical properties, which has resulted in increased academic interest.

Natural Ceramic Membrane Materials

* Zeolite

Natural zeolite possesses a unique porous structure, an enhanced specific surface area and abundant hydroxyl groups on its surface. Processing natural zeolite into ceramic separation membranes can reduce production costs and provide an alternative method for manufacturing ceramic membranes.

* Fly Ash

Fly ash is a waste by-product from thermal power stations that poses environmental challenges. The content of Al2O3 and SiO2 in fly ash is approximately 8.65 %. When sintered at high temperatures, mullite is formed. Mullite exhibits high fire resistance, a low coefficient of thermal expansion, good chemical stability and thermal stability. Consequently, fly ash can be used to manufacture high-performance ceramic membranes and facilitate recycling.

* Kaolin

Kaolin (Al2O3-2SiO2-2H2O), also known as hydrated aluminosilicate porcelain earth, is an important non-metallic mineral resource. It has attracted growing attention in the field of ceramics due to its low cost and effective performance.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento