What Are The Uses Of Molybdenum

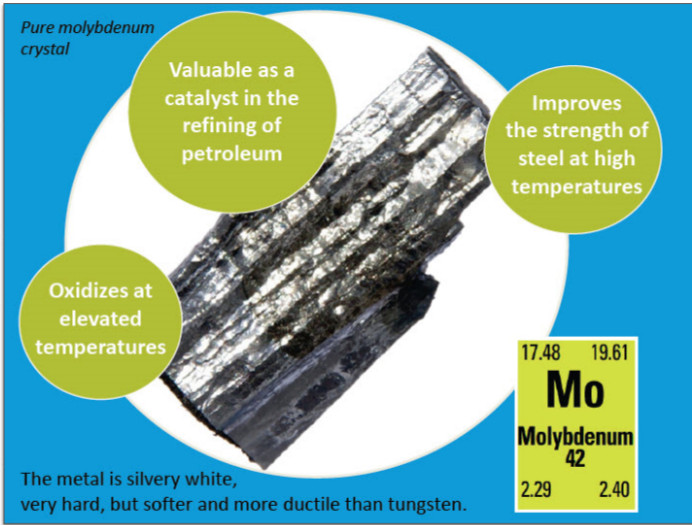

In 1782, Elm of Sweden used a mixture of linseed oil, charcoal and molybdic acid for sealed combustion. Consequently, molybdenum was obtained. Molybdenum is a silvery‑white metal. It is hard and ductile and does not undergo air corrosion at room temperature. It does not react with hydrochloric acid or hydrofluoric acid. Molybdenum is used chiefly in the steel industry (80 %) and in the chemical industry (approximately 10 %). Additionally, it is employed in the electrical and electronics industry, in medicine, in agriculture and in other sectors. Molybdenum

The Application of Molybdenum in the Steel Sector:

In the steel sector, molybdenum is used primarily in the production of alloyed steel, stainless steel, tool steel, high‑speed steel, cast iron and rolls. The addition of molybdenum increases the strength, ductility, corrosion resistance and wear resistance of steel. It also improves hardenability, weldability and heat resistance. Adding other elements to molybdenum, as in the molybdenum–lanthanum alloy and the TZM alloy, produces alloys that perform better than pure molybdenum.

The Application of Molybdenum in the Chemical Sector:

In the chemical industry, molybdenum is used as a lubricant, a catalyst, a pigment, a flame retardant and a smoke suppressant, as well as a corrosion inhibitor for organic polymers. The principal products include molybdenum trioxide, molybdenum yellow, molybdate and ammonium paramolybdate.

The Application of Molybdenum in Electronic and Electrical Sectors:

Molybdenum exhibits good electrical conductivity and high temperature resistance. Its coefficient of thermal expansion is comparable to that of glass. It is used in the production of core wire, lead wire, hooks and other components of spiral filaments. Molybdenum wire is used as the electrode wire for cutting tool machines that process various steels and cemented carbides. This method improves the precision of machine parts.

The Application of Molybdenum in the Medical, Livestock and Agricultural Sectors:

Molybdenum is one of the essential trace elements in the human body. An appropriate quantity of molybdenum supports human development, increases oxygen storage and inhibits tumour formation. Ammonium molybdate is used as the active ingredient in pharmaceuticals. In animals, molybdenum forms part of an enzyme complex. The addition of molybdenum supplements to feed meets the animals’ requirements. It is also a key trace element for plant growth. The application of ammonium molybdate can significantly increase the yield of flowers.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento