YAG Vs. YIG Crystals: A Comparative Analysis

1 Introduction

Garnet refers to a group of silicate minerals that crystallise in the cubic system. In nature, they display a varied range of colours and physical properties due to the presence of divalent and trivalent metal ions (e.g. Mg2+, Fe3+, Al3+). Their high hardness and chemical stability allow their use as gemstones and industrial abrasives. Recent scientific advances have led to the development of synthetic garnet materials by exchanging metal ions within the lattice. In particular, Yttrium Aluminium Garnet (YAG, Y3Al5O12), which contains Al3+ ions, is used in lasers (e.g. Nd:YAG) and optics because of its high thermal conductivity and broad optical transparency. Yttrium Iron Garnet (YIG, Y3Fe5O12) finds application in optical devices due to its magnetically induced effects. Although both belong to the garnet family, differences in composition result in marked variations in optical and magnetic functions. This paper compares the crystal structures, key properties, application scenarios, and selection criteria of YAG and YIG by analysing the following aspects:

- Structural differences: the impact of Al3+ and Fe3+ on lattice characteristics;

- Performance comparison: principal parameters involving optical, electromagnetic, thermal, and chemical stability;

- Application divergence: suitability for laser technology, microwave devices, magneto-optical modulation and other fields;

- Selection criteria: a framework based on working conditions, functional requirements and cost efficiency.

This analysis clarifies the functional differences and complementary potentials of the two material types. It provides scientific references for material selection in the development of optoelectronic, microwave and magnetic devices.

Fig. 1 Garnet Crystal

2 Material Properties and Crystal Structure

2.1 YAG (Y3Al5O12)

The chemical composition of Yttrium Aluminium Garnet (YAG, chemical formula Y3Al5O12) is closely linked to its crystal structure. It is essentially a synthetic garnet-like oxide crystal with a cubic system. YAG forms a highly symmetrical three-dimensional network with yttrium (Y3+), aluminium (Al3+) and oxygen (O2–) as the basic units. Yttrium ions occupy dodecahedral sites, and aluminium ions fill the octahedral and tetrahedral interstices. This network of [YO8]-dodecahedra, [AlO6]-octahedra and [AlO4]-tetrahedra, connected via common vertices, results in a high hardness (Mohs hardness of approximately 8.5) and mechanical stability. It exhibits a thermal conductivity of around 14 W/m-K and a spectral transmission range from 300 nm in the UV to 5 μm in the infrared. The non-magnetic properties of the aluminium ions and the ordered crystal lattice yield low intrinsic absorption from the visible to near-infrared range. YAG is therefore an efficient host for rare-earth ion dopants (e.g. Nd3+) which produce laser emission. Its high thermal conductivity aids in dissipating heat generated during laser operation, thereby reducing degradation caused by thermal lensing. These reliable optical and thermal properties make YAG suitable for high-power laser media, optical windows and radiation detection.

Fig. 2 Yttrium Aluminium Garnet (YAG) Crystal

2.2 YIG (Y3Fe5O12)

Yttrium Iron Garnet (YIG, chemical formula Y3Fe5O12) is a magnetic oxide crystal that is based on the garnet structure of the cubic system. It comprises yttrium (Y3+), iron (Fe3+) and oxygen (O2–) arranged in a magnetically functional lattice. Yttrium ions occupy dodecahedral positions, while Fe3+ ions are distributed over octahedral and tetrahedral sites. The Fe3+ ions at octahedral sites, in combination with the tetrahedrally coordinated oxygen, form a rigid lattice. This structure exhibits high symmetry and provides YIG with ferromagnetic properties (Curie temperature of approximately 560 K) and magneto-optical effects induced by 3d electron orbital coupling and spin order. When exposed to a microwave frequency magnetic field, the collective precession of the iron ion spins produces ferromagnetic resonance. The resulting adjustable permeability and energy absorption in the 1–100 GHz band are essential for devices such as circulators and isolators. The Faraday rotation effect in YIG, which rotates the plane of polarisation, is used in optical isolators and magneto-optical storage devices in the near-infrared range (1.3–1.5 μm). Furthermore, the microwave absorption characteristics are related to its lattice damping and magnetic anisotropy. Doping techniques (e.g. substituting Y3+ with Bi3+) can further optimise YIG to meet the requirements of 5G communication and radar systems. In summary, the magnetic function of YIG is closely linked to its electronic configuration, establishing its role as a necessary material in magnetophotonics and microwave technology.

Fig. 3 Yttrium Iron Garnet (YIG) Crystal Substrates

2.3 Structural Comparison

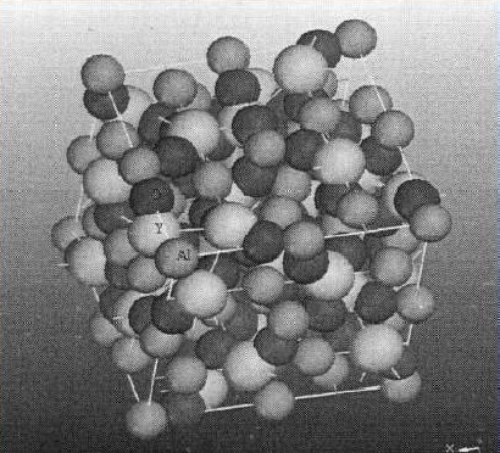

Yttrium Aluminium Garnet (YAG, Y3Al5O12) and Yttrium Iron Garnet (YIG, Y3Fe5O12) belong to the garnet family with cubic symmetry. The key differences stem from the distinct chemical properties of Al3+ and Fe3+, which occupy crucial lattice positions. In YAG, Al3+ ions are distributed between octahedral and tetrahedral sites, forming a highly symmetric and non-magnetic Al–O network. The 3s²3p⁰ electron configuration of Al3+ results in a lack of unpaired electrons and minimal optical absorption. The strong Al–O bonds also provide high binding energy and ordered lattice structure, thereby ensuring broad optical transmission from 300 nm to 5 μm and a thermal conductivity of around 14 W/m-K. These attributes are essential for high-performance laser media and optical windows. Conversely, in YIG, Fe3+ ions exclusively occupy octahedral sites. The 3d⁵ electrons generate a high-spin state that, through superexchange interactions with neighbouring ions, establish long-range ferromagnetic order. This magnetic lattice produces ferromagnetic resonance and significant Faraday rotation (up to 200°/cm in the near-infrared). Consequently, YIG is widely used in microwave devices and magneto-optical systems. Although each material has distinct functions, the possibility to adjust the garnet structure allows for the development of composite materials (e.g. YAG–YIG heterostructures) for future integrated photonics and multiphysics devices.

Fig. 4 Garnet Crystal Structure Model

3 Comparison of Key Performance Characteristics

3.1 Optical Properties

YAG and YIG exhibit distinct optical properties. YAG’s optical behaviour relies on laser amplification. The non-magnetic nature of Al3+ and the ordered lattice produce minimal optical loss between 300 nm and 5 μm. It is the preferred medium to be doped with rare-earth ions, for instance Nd3+. Neodymium-doped YAG (Nd:YAG) typically has a fluorescence lifetime of approximately 230 µs, facilitating adequate accumulation of excited states. With a damage threshold exceeding 1 GW/cm², it generates stable near-infrared laser radiation at 1064 nm. YAG is used in industrial cutting, medical surgery and research in ultrafast laser systems. Its broad transmission window permits usage in windows, lenses and scintillator materials across UV to mid-infrared wavelengths, even under high temperatures or radiation environments.

YIG’s optical properties are defined by magneto-optical effects. The 3d⁵ electrons of Fe3+ produce a Faraday effect that rotates the plane of polarisation. For example, in the 1550 nm communication band, YIG can achieve a Faraday rotation of approximately 200°/cm. This property is exploited in optical isolators to enforce unidirectional light transmission and prevent laser destabilisation from reflected light. While YIG does show some absorption in the visible range due to d–d transitions, it maintains a transparent window in the near- to mid-infrared (1.2–5 μm). Adjustments by doping (e.g. substituting Bi3+ for Y3+) further improve its magneto-optical response. The technical differences relate directly to the mechanisms by which light interacts with these materials: YAG utilises photon resonance with rare-earth energy levels while YIG employs photonic coupling with magnetic moments. Consequently, YAG predominates in laser emission and optical transmission, whereas YIG is essential for non-reciprocal optical devices.

Fig. 5 YAG Metal Laser Welding Machine

3.2 Electromagnetic Properties

Differences in electromagnetic properties arise from the distinct electronic behaviour of Al3+ and Fe3+. YAG exhibits insulating properties with a high specific resistance (greater than 10^16 Ω-cm) and a low dielectric loss factor (tan δ less than 10⁻⁴) in the microwave band. These characteristics make it suitable for high-frequency circuitry, RF windows and encapsulation of high-power lasers. For instance, in a laser diode substrate, YAG effectively limits leakage current and copes with prolonged exposure to high-frequency fields.

In contrast, YIG’s electromagnetic characteristics are dominated by the magnetic properties of Fe3+. Its octahedrally coordinated Fe3+ ions, via superexchange, produce a saturation magnetisation of approximately 178 emu/cm³ and an adjustable microwave permeability. In a varying magnetic field, YIG produces ferromagnetic resonance with frequencies typically tunable between 1 and 100 GHz. These features make YIG suitable for microwave circulators, isolators and filters, especially in 5G base stations where unidirectional signal transmission is required. Although YIG exhibits a higher conductivity (approximately 10^8 Ω-cm), this is attributed to the d-electrons’ contribution in charge transport. The ferromagnetic resonance loss may be further reduced by appropriate lattice doping (e.g. Ga3+ substitution for Fe3+).

Thus, YAG serves effectively in scenarios where electrical insulation and high-frequency stability are needed, whereas YIG is used where magnetic activity and microwave signal processing are essential. Given that both materials have clearly defined electrical roles, their integration in composite substrates may provide benefits in specialised applications.

Fig. 6 Magneto-Optical Memory (MOM)

3.3 Thermal and Mechanical Properties

YAG exhibits a thermal conductivity of roughly 14 W/m-K and a low thermal expansion coefficient (approximately 8×10⁻⁶/K), due to the strong ionic-covalent bonds between Al3+ and O2– and the ordered crystal lattice. This enables rapid heat dissipation and minimises deformation due to thermal stress at temperatures exceeding 1 700 °C or during high-power laser operation. In Nd:YAG lasers, the high thermal conductivity controls deviations of laser modes caused by thermal lensing. The Mohs hardness of YAG is about 8.5, ensuring surface integrity even in adverse environments such as aerospace optics or high-energy particle detection.

YIG, by contrast, shows a lower thermal conductivity of between 3 and 5 W/m-K and a higher thermal expansion coefficient (roughly 10×10⁻⁶/K). This is partly due to the influence of d-electrons on lattice vibrations as well as additional lattice distortions from magnetostrictive effects. Although its Curie temperature is approximately 560 K, the ferromagnetic order weakens near this temperature and the magneto-optical effectiveness decreases. Hence, YIG is typically used at temperatures below 200 °C. The Mohs hardness of YIG ranges from about 6.5 to 7. Its mechanical performance is satisfactory given its application in microwave cavities or magneto-optical thin film devices. It should be noted that YIG’s magnetic parameters are temperature sensitive; with rising temperature, the saturation magnetisation decreases and the linewidth of ferromagnetic resonance broadens, thereby necessitating compensatory design measures or active temperature control in high-frequency applications.

The technical implications are as follows:

- YAG: In environments with high temperatures, significant heat flux or mechanical wear (e.g. laser welding heads, optical windows used in space research), its high thermal conductivity, low thermal expansion and high hardness offer distinct advantages.

- YIG: Despite its lower thermal management capacity, its tunable magnetic properties and microwave behaviour render it indispensable in systems dominated by magnetic fields such as 5G RF front ends and magnetic sensor applications. Thermal limitations are mitigated through appropriate designs.

3.4 Chemical Resistance

YAG exhibits excellent corrosion resistance due to its strong Al–O network. The robust chemical bonds between Al3+ and O2– retain the material’s stability in ambient or elevated temperatures. In humid environments or mildly acidic/alkaline media (pH 3–11), the surface undergoes minimal hydrolysis. Accelerated ageing tests at 85% relative humidity and 85 °C have shown a weight loss of less than 0.01% per annum without the development of discernible corrosion pits. This property makes YAG suitable for applications such as outdoor LIDAR and radiation detection in nuclear settings.

YIG displays a lower corrosion resistance as a result of the oxidation tendency of Fe3+, particularly at temperatures above 300 °C or in oxidising atmospheres. Over extended periods in humid air, a loosely attached oxidised layer may form, with a thickness of several micrometres per annum, causing a reduction in the Faraday rotation by 10–20%. Protective measures, such as a thin SiO2 coating or encapsulation in an inert atmosphere, are therefore required. YIG also reacts adversely in acidic environments (pH below 5), where H⁺ ions may erode Fe–O bonds and lead to lattice dissociation.

The technical compromises regarding environmental adaptation are summarised as follows:

- YAG: Its chemical inertness and high-temperature stability allow it to withstand moisture, salt mist, weak acids/bases (pH 3–11) and oxidising high-temperature conditions. It is therefore appropriate for long-term outdoor exposure and nuclear radiation detection.

- YIG: It requires protection from high-temperature oxidation and acid corrosion. However, under controlled conditions (dry or inert atmospheres, or vacuum encapsulation), YIG performs reliably. For example, hermetically sealed designs in 5G base stations or magneto-optical isolators can extend device lifetime significantly.

4 Analysis of Application Scenarios

4.1 Typical Applications of YAG

1. Laser Technology: The Foundation of Solid-State Lasers

In industrial cutting and welding, neodymium-doped YAG crystals serve as the gain medium in continuous or pulsed lasers. These lasers operate at power levels in the kilowatt range and are used for precision cutting of metals (for example, titanium alloys used in aerospace). The high thermal conductivity of YAG controls heat build-up and avoids thermal-induced distortions.

In medical surgery, near-infrared Nd:YAG lasers (1064 nm) are used for tissue interaction in operations such as retinal repairs, urological stone disintegration and tumour removal. Their output often meets energy requirements within tight temporal windows.

Fig. 7 Nd:YAG (Neodymium-doped Yttrium Aluminium Garnet)

Erbium-doped YAG emits in the mid-infrared at a wavelength corresponding to the water absorption peak (approximately 3 μm). This permits precise evaporation of the surface of biological tissue (for skin resurfacing or scar reduction) or of dental enamel. In such procedures, the reduction of thermal damage is quantifiable.

YAG is also used as a substrate in conjunction with laser diodes (for example, 808 nm pump sources) to improve electro-optical conversion efficiency by more than 30%, which benefits fibre-optic communications and industrial laser systems.

Fig. 8 Er:YAG (Erbium-doped Yttrium Aluminium Garnet)

2. Optics: Materials Suitable for Extreme Conditions

High-Power Laser Windows and Lenses:

YAG’s broad wavelength transmission (300 nm–5 μm) and a high damage threshold (greater than 1 GW/cm²) make it the material of choice for windows and focusing lenses in high-energy laser systems. These components are required to operate without thermal cracking or optical distortion.

Scintillator Detectors:

Cerium-doped YAG (YAG:Ce) emits green fluorescence at 550 nm with a response time of approximately 70 ns when exposed to high-energy particles (X‑rays or γ‑rays). It is employed in nuclear medicine (PET imaging), high-energy physics (particle detection) and security CT systems. Its radiation hardness is superior to that of conventional NaI(Tl) crystals.

3. Industrial and Medical Applications: Tools for Precise Energy Management

Industrial Laser Processing:

YAG lasers produce nanosecond pulses that are used for microvia drilling in printed circuit boards, surface texturing, and precision marking of medical devices. The beam quality (M² below 1.1) facilitates sub-micrometre processing accuracy.

Medical Aesthetics:

Q-switched Nd:YAG lasers are employed in tattoo and pigmentation removal. The 1064 nm wavelength targets melanin in the dermis with reduced absorption in the epidermis. Long-pulsed Nd:YAG lasers are used for hair removal, penetrating 4–6 mm and suitable for darker skin types.

Treatment of Dental Hard Tissues:

The Er:YAG laser (2940 nm) is strongly absorbed by water molecules. This leads to micro-explosions in enamel and dentin that facilitate cavity preparation with significantly reduced patient discomfort compared to traditional drills.

Table 1: Rationalisation of YAG Applications

|

Application Scenario |

Key Properties |

Challenges with Alternative Materials |

|

High-Power Lasers |

High thermal conductivity and minimal thermal lensing |

Lower thermal conductivity in sapphire, glass, and susceptibility to thermal cracking |

|

Scintillator Detectors |

Fast decay time and high radiation hardness |

Plastic scintillators age rapidly, and BGO crystals exhibit slower responses |

|

Medical Lasers |

Matches water absorption and tissue penetration depths |

CO₂ lasers (10.6 μm) exhibit surface-limited effects |

4.2 Typical Applications of YIG

1. Microwave and RF Devices: Regulating High-Frequency Signals

YIG exhibits ferromagnetic resonance properties that render it suitable for microwave signal processing. Its adjustable permeability and energy absorption in the 1–100 GHz band are essential in these applications.

Circulators and Isolators:

In radar, satellite communications and 5G base stations, YIG-based circulators adjust the ferromagnetic resonance frequency using an applied magnetic field, thereby achieving unidirectional microwave signal transmission and preventing reflection-induced interference. For example, in 5G massive MIMO arrays at millimetre-wave frequencies, YIG isolators maintain insertion losses below 0.5 dB and isolation above 20 dB.

Microwave Filters and Phase Shifters:

YIG’s frequency-dependent permeability is employed in bandpass filters, where the centre frequency can be tuned by varying a bias magnetic field. Its well-defined hysteresis makes it useful in phase shifters for radar systems, where microwave phase is controlled via the magnetisation state.

2. Magneto-Optical Devices: Modulating Optical Paths

The Faraday rotation effect in YIG, which rotates the plane of polarisation under a magnetic field, is central to optical communications and magneto-optical storage systems.

Optical Isolators and Circulators:

In fibre-optic communication systems, YIG-based optical isolators utilise the non-reciprocal Faraday rotation to force a specific polarisation state and achieve optical isolation greater than 30 dB, thereby protecting laser diodes from optical feedback. A YIG isolator designed for the 1550 nm band, with a rotation of up to 200°/cm and losses below 0.2 dB, serves as a standard component in high-speed optical modules.

Magneto-Optical Modulators and Storage:

Variation in the Faraday rotation angle in YIG induced by a magnetic field converts an electrical signal into a change in light intensity or polarisation state. This is applied in direct optical modulation or polarisation encoding in quantum key distribution. Studies on controllable magnetic domains in YIG films have also informed applications in magneto-optical storage, despite a shift in primary storage technologies to solid-state devices. Their high density and radiation resistance maintain potential in specific applications, such as space-based data storage.

3. Sensors: High-Sensitivity Magnetic Field Detectors

YIG’s magneto-optical response and sensitivity to external magnetic fields make it a material of choice for detecting weak magnetic fields and for magnetic imaging.

Magneto-Optical Sensors:

Sensors based on Faraday rotation, which can resolve magnetic field strengths with accuracies reaching the nanotesla range (with the geomagnetic field being approximately 50 μT), are utilised in geological surveys, biomedical applications (such as magnetocardiography) and in power grid fault localisation. For instance, bismuth-doped YIG (Bi:YIG) can enhance the Faraday rotation by a factor of 10⁴ °/cm, significantly improving sensitivity.

Microwave Magnetic Field Imaging:

YIG probes are used to map electromagnetic properties (e.g. dielectric constant, permeability) by scanning the microwave near-field of a sample and detecting shifts in ferromagnetic resonance frequency for applications such as IC defect identification or characterisation of metamaterials at sub-millimetre spatial resolution.

Table 2: Rationalisation of YIG Applications

|

Application Scenario |

Key Properties |

Limitations of Alternative Materials |

|

Microwave Circulators |

Tunability of high-frequency ferromagnetic resonance |

Narrow bandwidth in ferrites and high semiconductor losses |

|

Optical Isolators |

High Faraday rotation and low optical loss |

Terbium glass exhibits a low rotation angle; TGG crystals incur high costs |

|

Magneto-Optical Sensing |

Magnetic field sensitivity with linear response |

Hall sensors show significant temperature drift; SQUID systems require low operating temperatures |

4.3 Cross-Sectional Applications and Emerging Areas

Research on YAG and YIG addresses the integration of optical and magnetic materials. YAG is noted for its broad spectral transmission, high thermal conductivity and mechanical stability. YIG is valued for its ferromagnetic resonance and magneto-optical effects in microwave and photonic modulation. The combination of these materials offers opportunities for composite devices using heterogeneous integration techniques, such as ion slicing and thermal bonding. For example, on-chip optical isolators that combine magneto-optical YIG films with YAG laser media have demonstrated insertion losses of 2.78 dB and 0.35 dB in the 1.55 μm and 2.1 μm wavelength bands respectively, with isolation bandwidths of 83 nm and 84 nm. The high thermal conductivity of YAG (around 14 W/m-K) reduces the risk of thermal degradation in YIG within high-power laser systems. Researchers have also reduced the sintering temperature of YIG by doping with Bi3+, from 1 450 °C to 950 °C. Bi:YIG ceramics with a ferromagnetic linewidth under 200 Oe are now compatible with low-temperature co-firing (LTCC) technologies, which may support scaled production of microwave circulators and magneto-optical devices. Furthermore, multilayer YAG/Nd:YAG gradient composite laser ceramics have been joined by thermal compression to form a gradient heat dissipation structure. This arrangement has increased optical conversion efficiency by 19.85% and reduced thermal lensing by 50%, setting a model for managing heat in high-energy laser systems.

In the fields of quantum technology and ultrafast optics, YAG/YIG composites show potential in integrated quantum interfaces. Experiments at Stanford Advanced Materials have demonstrated magnetic vibron–microwave–photon coupling between two YIG spheres spaced 1 cm apart, mediated by superconducting circuits. Such demonstrations establish a physical foundation for distributed quantum networks. Studies using ultrafast pump–probe techniques have also observed periodic oscillations in photon distribution at α-quartz interfaces, which supports the design of optically controlled spin-wave devices. In the mid-infrared, the low absorption (α = 0.053 cm⁻¹) and high magneto-optical coefficient of YIG ceramics in the 2.1 μm band, combined with the durability of YAG, have enabled magneto-optical modulation of pulsed lasers with peak powers exceeding 10 GW. These findings extend the capabilities in molecular fingerprint spectroscopy and quantum key distribution.

Current practical implementations of YAG/YIG composites face challenges. Lattice mismatch issues arise due to differences in lattice constants (YAG: 12.01 Å vs YIG: 12.38 Å) and thermal expansion coefficients (YAG: circa 8×10⁻⁶/K vs YIG: circa 10×10⁻⁶/K). Such issues must be addressed through gradient doping or nano-heterojunction design. In addition, improvements in quantum coherence require suppression of lattice defect scattering in the magnetic YIG oscillators. Techniques such as the use of ultra-pure single crystals or encapsulation at temperatures below 4 K have increased spin coherence times from nanoseconds to microseconds. Combined modulation approaches using femtosecond pulses to temporarily alter magnetic states and real-time analysis of spin wave propagation are being explored. These approaches may guide the integration of topological magnetic and optically controlled spintronic devices in the future.

Future work on YAG/YIG composites is expected to enable developments in integrated photonics, quantum information and ultrafast technologies. Advances in atomic-scale interfacial techniques and functional coupling of macroscopic devices will likely accelerate applications in optical quantum computing, 6G terahertz communication and intelligent sensor systems, thereby reshaping aspects of future information technology.

Further Reading:

Case Study: How Ytterbium-Doped Yttrium Aluminium Garnet Impacts Optical Innovations

An Introduction to Seven Types of Synthetic Garnet Materials

GGG vs GGAG vs TGG Garnet Crystals: A Comparative Analysis

The Role of GGG, SGGG and NGG Garnet Boules

Yttrium Aluminium Garnet (YAG): From Laser Technology to Diverse Fluorescent Applications

5 Conclusion

The research comparing YAG and YIG outlines the limits of traditional functional materials. Heterogeneous integration using low-temperature co-firing techniques has yielded performance improvements in optical isolators, high-energy laser systems and microwave devices. Studies on quantum interfaces and ultrafast modulation have highlighted the potential for applications in distributed quantum networks and molecular-scale analysis. Although challenges remain in interface engineering and quantum coherence improvement, YAG/YIG composites are expected to be key in optical quantum computing, 6G communications and intelligent sensor systems. Advanced nanoprecision preparation methods will assist in transferring laboratory developments into industrial manufacturing and provide a redefined foundation for future information technology.

Further Reading:

Case Study: How Ytterbium-Doped Yttrium Aluminium Garnet Impacts Optical Innovations

An Introduction to Seven Types of Synthetic Garnet Materials

GGG vs GGAG vs TGG Garnet Crystals: A Comparative Analysis

The Role of GGG, SGGG and NGG Garnet Boules

Yttrium Aluminium Garnet (YAG): From Laser Technology to Diverse Fluorescent Applications

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento