Lithium-Sulfur Batteries Vs. Lithium-Ion Batteries: A Comparative Analysis

Introduction

Electric vehicles are undergoing significant modification, and the core of this change is provided by lithium–sulphur (Li-S) batteries. These batteries offer several quantifiable advantages over standard lithium-ion (Li-Ion) batteries. This article outlines the measured benefits that Li-S batteries offer compared with Li-Ion batteries, thereby contributing to a cleaner and more sustainable mode of transport.

Understanding Lithium-Ion Batteries (Li-Ion)

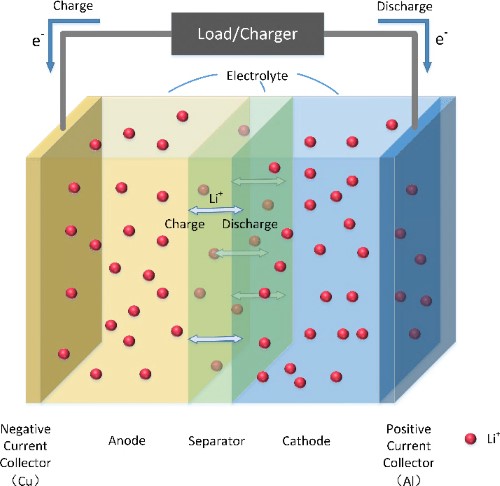

Lithium-ion batteries or Li-Ion batteries currently serve as the standard power source for a range of portable electronic devices. They operate based on the migration of lithium ions between the positive (cathode) and negative (anode) electrodes. During discharge the lithium ions move from the anode to the cathode, thereby generating electrical energy. Owing to properties such as a high energy density, extended lifespan and relatively low weight, lithium-ion batteries have become the standard choice for electric vehicles (EVs).

[1]

[1]

Figure 1. Lithium-ion Batteries (Li-Ion)

Lithium–sulphur Batteries (Li-S)

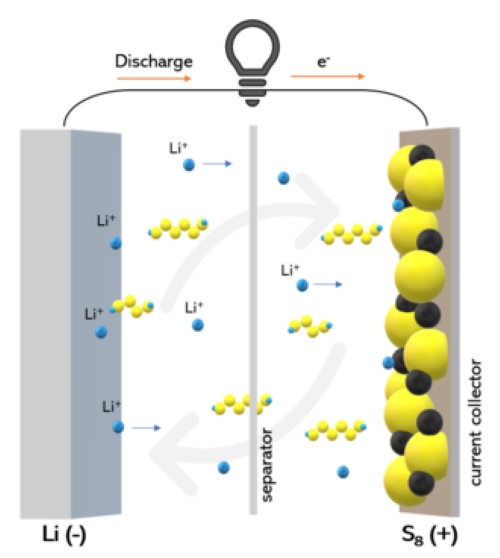

Lithium–sulphur batteries (Li-S) have emerged as a promising alternative to conventional lithium-ion batteries (Li-Ion) and are utilised in electric vehicles. Li-S batteries operate via a different electrochemical reaction; sulphur is employed as the cathode while lithium metal or lithium ions serve as the anode. In comparison to Li-Ion batteries, Li-S batteries offer a higher theoretical energy density, reduced weight and lower production costs, thereby making them attractive for electric vehicles and other applications.

[2]

[2]

Figure 2. Lithium–sulphur Batteries (Li-S)

Lithium–sulphur Batteries vs. Lithium-Ion Batteries

The following section lists the attributes and limitations of lithium–sulphur and lithium-ion batteries and describes their potential to influence the future of electric vehicles.

1. Energy Density:

Li-S batteries exhibit a theoretical energy density that exceeds that of lithium-ion batteries. Consequently, EVs equipped with Li-S batteries can potentially store more energy per unit volume and weight, thereby achieving extended driving ranges.

2. Weight Efficiency:

Sulphur, a key component in Li-S batteries, is abundant and light. The reduced mass leads to a lower overall vehicle weight and improved energy efficiency. Lighter electric vehicles thus require less energy to operate and can deliver an extended battery life.

3. Fast Charging Capability:

One significant characteristic of these batteries is their fast charging capability. The high conductivity enables shorter charging times, thereby resulting in charging durations that approach those required for fossil fuel refuelling. This capability addresses the issue of range anxiety among EV users.

4. Cost Reduction:

Sulphur is an inexpensive material, which reduces production costs for Li-S batteries in comparison with lithium-ion batteries that utilise materials such as cobalt, which are expensive and subject to supply chain constraints.

5. Environmental Impact:

Li-S batteries may have a lower environmental impact than their Li-Ion counterparts. Sulphur is readily available and cost-effective, and its extraction and processing require fewer resources compared with minerals such as cobalt. Moreover, the simpler composition of Li-S batteries may allow for more straightforward recycling and a reduced ecological footprint.

6. Cycle Life:

Lithium-ion batteries generally offer a longer cycle life than Li-S batteries. Historically, Li-S batteries have recorded a shorter cycle lifetime, primarily due to the dissolution of sulphur in the electrolyte during charge and discharge cycles. Researchers are actively working to improve the cycle life of Li-S batteries.

7. Safety:

Lithium-ion batteries have demonstrated safety in EV applications. Conversely, Li-S batteries have shown safety challenges, given that the formation of lithium sulphide may occur and is potentially unstable. Ensuring the safety of lithium-ion batteries remains a focus in ongoing research and development.

Further Reading: An Overview of Lithium Applications

Conclusion

In summary, the quantifiable advantages of lithium–sulphur batteries are likely to affect the field of electric vehicles. With a high energy density, reduced weight, lower production costs, fast charging capability and limited environmental impact, Li-S batteries offer a viable alternative to conventional lithium-ion batteries. As research and development progress, Li-S batteries are advancing, thereby supporting the move towards a cleaner and more sustainable future in electromobility.

Stanford Advanced Materials (SAM) is a leading provider of a range of products, including lithium-ion batteries and various advanced battery technologies. Please send us an enquiry if you are interested.

Reference:

[1] An Overview on Thermal Safety Issues of Lithium-ion Batteries for Electric Vehicle Application - Scientific Figure on ResearchGate. Available at: https://www.researchgate.net/figure/Schematic-of-the-Lithium-ion-battery_fig2_324929541 [Accessed on 07/09/2023]

[2] Lithium–sulphur Battery. (20/08/2023). In Wikipedia. https://en.wikipedia.org/wiki/Lithium%E2%80%93sulfur_battery

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento