Precious Metal Catalysts For The Petroleum Sector

Introduction

Precious metals such as platinum, palladium, rhodium and gold are used as catalysts in many industrial processes due to their distinctive physical and chemical characteristics. These metals exhibit high corrosion resistance, high melting points and stable catalytic performance. They are able to withstand harsh conditions and maintain their catalytic properties over extended operational periods.

Precious metal catalysts are a standard component in the petroleum industry. They are employed in the refining of crude oil into usable products such as petrol, diesel and aviation fuel, thereby accelerating the refining process and increasing both yield and product quality. In this article we examine the various types of precious metal catalysts used in the petroleum sector and outline their technical advantages. The aim is to provide a clearer understanding of their properties and applications.

Figure 1. Precious Metal Catalysts

Types of Precious Metal Catalysts Used in the Petroleum Industry

There is a variety of precious metal catalysts employed in the petroleum industry. The main types and their applications are summarised below.

- Platinum catalysts: Platinum is frequently used in refinery processes, particularly during reforming. These catalysts are used to convert low-octane naphtha into high-octane petrol. They are also applied in isomerisation, whereby linear hydrocarbons are converted into their branched isomers.

- Palladium catalysts: Palladium is commonly employed in the petroleum industry, especially in hydrogenation reactions. These catalysts convert unsaturated hydrocarbons into saturated hydrocarbons, an important step in the production of diesel fuel.

- Ruthenium catalysts: Ruthenium catalysts are used in the petroleum industry for the production of ethylene, which is an essential precursor for many petrochemical products including plastics, synthetic rubbers and resins.

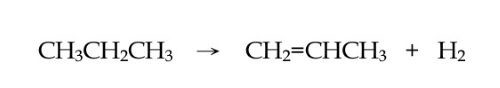

- Other precious metal catalysts: Precious metal catalysts are also employed in the dehydrogenation of propane (see Figure 2) and in the production of high-purity cyclohexane.

Figure 2. Dehydrogenation of Propane with Pt/Al2O3

Advantages of Precious Metal Catalysts in the Petroleum Industry

Precious metal catalysts offer numerous advantages in the petroleum industry. They enhance the efficiency of chemical reactions, reduce operating costs and decrease environmental impact. Additional advantages include:

- Enhanced efficiency: Precious metal catalysts accelerate reaction rates, thereby increasing processing efficiency and overall productivity.

- Increased yield: These catalysts contribute to higher yields of refinery products such as petrol and diesel by converting lower-grade feedstocks into higher-grade products.

- Improved quality: They facilitate the removal of impurities such as sulphur and nitrogen from feedstocks, which results in cleaner products.

- Longer catalyst lifespan: Precious metal catalysts generally have a longer service life than conventional catalysts, which reduces the need for frequent replacement and results in cost savings.

- Better selectivity: Precious metal catalysts are highly selective. They reduce the formation of undesired by-products and increase the purity of final products. For example, palladium catalysts are employed in reactions such as hydrogenation, cross-coupling and carboxylation due to their favourable selectivity. Additionally, platinum catalysts are used for the selective production of cyclohexane.

Further reading: Advantages of Precious Metal Catalysts

Conclusion

The application of precious metal catalysts has improved the efficiency, yield and quality of refinery processes. Platinum, palladium and ruthenium are the most frequently used catalysts in industrial applications. Given that there is an increasing demand for cleaner and more efficient fuels, these catalysts are expected to continue playing an important role in petroleum refining.

Stanford Advanced Materials (SAM) has extensive experience in the manufacture and distribution of various precious metal catalysts. We offer precious metal crucibles, precious metal wires and other precious metal products at competitive prices. Please send us an enquiry if you are interested.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento