Segregation In Alloy Casting: Types, Causes, And Mitigation

Introduction

Segregation in the casting of alloys is a critical phenomenon that affects the quality and performance of metals and alloys. It refers to the uneven distribution of alloying elements during the solidification process. This unevenness may cause measurable variations in the mechanical, chemical and physical properties, thereby reducing the overall performance.

Understanding the types, causes and measures to mitigate segregation is essential for producing high-quality alloys.

Types of Segregation

- Microsegregation:

Microsegregation occurs at a microscopic level within individual grains or between dendritic arms. During solidification, the dissolved elements tend to accumulate in regions that solidify last, most often at grain boundaries or in interdendritic areas. This can lead to local compositional variations that affect microstructural and mechanical properties.

- Macrosegregation:

Macrosegregation occurs at a macroscopic scale with significant composition variations throughout the casting or ingot. It can be visible to the naked eye and creates substantial fluctuations in the alloy properties. Macrosegregation is generally caused by the movement of the liquid phase during solidification, thereby resulting in an uneven distribution of the dissolved elements.

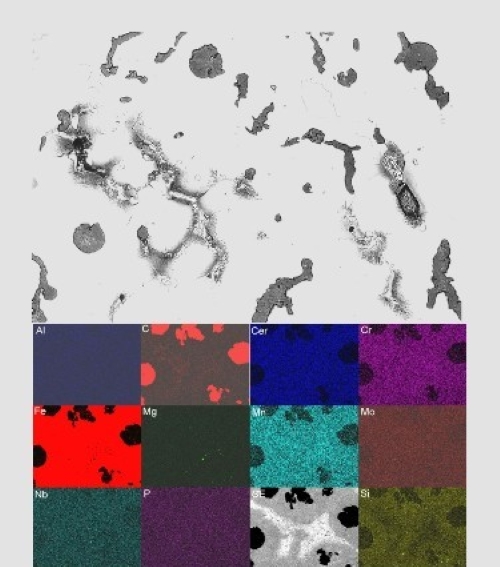

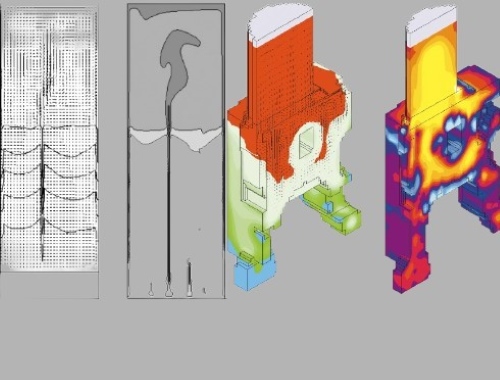

[1]

[1]

Causes of Segregation

1. Distribution Coefficient (k):

The distribution coefficient is defined as the ratio of the solute concentration in the solid phase to that in the liquid phase. When the coefficient is less than one (k < 1), the solute tends to remain in the liquid phase during solidification, thereby causing segregation. For example, in an aluminium-copper alloy, copper is more concentrated in the liquid phase during solidification.

2. Solidification Rate:

The rate at which an alloy solidifies influences the degree of segregation. Rapid cooling retains the dissolved elements within the liquid, which establishes a concentration gradient. Conversely, slow cooling allows time for the solute to redistribute, thereby reducing microsegregation while increasing the risk of macrosegregation, given the longer diffusion paths.

3. Density Differences:

Differences in density between the solute and solvent elements may cause segregation due to gravitational effects. Heavier elements settle at the bottom of the melt, whereas lighter elements tend to rise. Consequently, pronounced composition gradients may develop within the solidified alloy.

4. Thermal Gradients:

An uneven temperature distribution during solidification may lead to directional solidification, whereby the composition varies along the solidification front. Thermal gradients drive liquid flow within the melt, thereby increasing the extent of segregation.

5. Liquid Flow and Convection:

Natural or forced convection within the molten alloy can transport dissolved elements. Liquid flow, driven by thermal gradients, mechanical stirring or electromagnetic forces, leads to an uneven distribution of the alloying elements.

Mitigation Strategies

1. Control of Cooling Rate:

Adjusting the cooling rate is one of the most reliable methods to reduce segregation. Optimised cooling rates establish a balance between rapid and slow solidification. Controlled cooling profiles help maintain an even distribution of the solute. In directional solidification techniques, a regulated thermal gradient is applied to control solute distribution.

2. Stirring or Electromagnetic Processing:

Mechanical stirring or electromagnetic stirring improves the mixing within the melt. Mechanical stirring physically agitates the molten alloy, thereby promoting a homogeneous solute distribution. In electromagnetic stirring, electromagnetic fields produce liquid flow that enhances the distribution of solute and reduces segregation.

3. Grain Refinement:

The addition of nucleating agents or grain refiners encourages the formation of fine, equiaxed grains. This measure reduces the extent of segregation. For aluminium alloys, the addition of titanium or boron refines the grain structure, thereby leading to a more uniform distribution of the solute.

4. Directional Solidification Techniques:

Directional solidification techniques, such as zone refining, assist in controlling solute distribution. In zone refining, a molten zone is passed through the solid alloy, thereby allowing the solute to redistribute and reducing segregation. Control of the thermal gradient during solidification further produces a more uniform composition.

5. Homogenisation Heat Treatment:

Post-solidification heat treatment, known as homogenisation, promotes the diffusion of the solute and equalises compositional differences caused by segregation. The solidified alloy is heated to a temperature where diffusion is effective but remains below the melting point, thereby allowing solute redistribution.

6. Use of Alloys with Similar Melting Points:

Selecting alloying elements with similar melting points reduces the tendency for segregation. Alloys with closely matched melting points typically solidify uniformly, thereby minimising composition gradients.

Related Cases and Reports on Segregation in Alloy Casting

Below are several cases and reports that demonstrate the significance of segregation in various industrial and research contexts:

Case 1: Aerospace Industry – Titanium Alloys

"Control of Macrosegregation in Large Titanium Alloy Ingots" by J. D. Cotton and M. G. Burke describes how optimised vacuum arc remelting (VAR) processes and electromagnetic stirring techniques reduced macrosegregation in titanium alloy ingots. The study indicates that controlling solidification parameters and implementing effective stirring procedures improved the uniformity of the alloy composition, thereby enhancing the performance of aerospace components.

Case 2: Automotive Industry – Aluminium Alloys

"The Mitigation of Microsegregation in High-Strength Alloys for Automotive Applications" investigated microsegregation in aluminium-copper alloys. Researchers examined the effects of various cooling rates and homogenisation treatments on microsegregation patterns. They found that a combination of rapid cooling and subsequent homogenisation heat treatment reduced microsegregation, thereby achieving more uniform mechanical properties. These findings were applied to the manufacture of lightweight automotive components, with performance and durability improvements observed.

Case 3: Additive Manufacturing – Metal 3D Printing

"Microsegregation Control in Additively Manufactured Alloys" by A. D. Rollett and T. DebRoy investigated microsegregation in a number of additively manufactured alloys, including titanium and aluminium alloys. Researchers examined the effects of additive manufacturing process parameters, such as laser power and scanning speed, on microsegregation. They reported that optimising these parameters in combination with subsequent heat treatments significantly reduced microsegregation. The results support improved quality and performance of additively manufactured metal components for use in aerospace, medical and automotive applications.

Conclusion

Segregation in alloy casting has significant implications for the performance and reliability of metals and alloys. When metallurgists understand the types and causes of segregation, they can implement effective measures to prevent it and produce alloys with consistent properties.

Controlling the cooling rate, employing mechanical and electromagnetic stirring, grain refinement, directional solidification techniques, homogenisation heat treatment and careful alloy selection are all important measures to control and reduce segregation. These strategies must be tailored to specific alloy systems and applications to achieve quantifiable improvements in consistency. Further information is available at Stanford Advanced Materials (SAM).

Reference:

[1] K. J. B. R. W. C. .. P. V. (2001). Enzyklopädie der Werkstoffe: Wissenschaft und Technologie. https://www.sciencedirect.com/referencework/9780080431529/encyclopedia-of-materials-science-and-technology

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento