Sodium Hyaluronate Production Methods: Bacteria Fermentation Or Rooster’s Crowns?

Introduction

Natriumhyaluronat, the salt form of hyaluronic acid, is a naturally occurring polysaccharide. This material is present in the vitreous humour, dermis, synovial fluid and other parts of the human body, where it retains moisture and provides cushioning. In scientific and clinical applications it is used to improve skin moisture, skin structure and overall appearance.

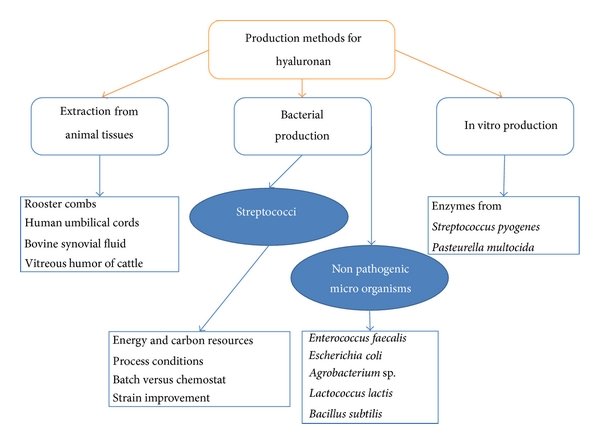

There exist two primary methods for producing Natriumhyaluronat, namely production from bacterial fermentation and extraction from rooster combs. In this article we detail these two methods and describe their respective advantages and disadvantages. We aim that readers gain a clearer understanding and may select the appropriate Natriumhyaluronat product for their research or enterprise.

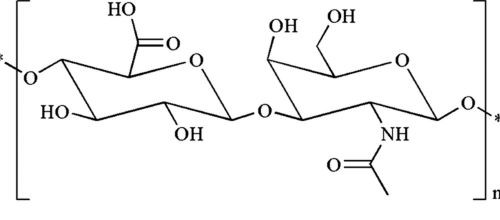

Figure 1. Chemical structure of HA

Production from Bacterial Fermentation

--The Fermentation Process

Bacterial fermentation is a widely used method for producing Natriumhyaluronat. In this method, bacterial strains such as Streptococcus equi or Streptococcus zooepidemicus are cultivated in a nutrient-rich medium. During their growth, the bacteria produce Natriumhyaluronat, which is then extracted and purified.

The microbial fermentation process is divided into the following steps:

- Initial product: Following fermentation, the bacteria are inactivated and the raw HA is precipitated using an organic solvent.

- Purification: The raw product is immersed in saline and further purified.

- Final product: The solution is subsequently precipitated with an organic solvent and dried to obtain the final HA product.

[2]

Figure 2. Production methods for Natriumhyaluronat

Further reading: Is hyaluronic acid extracted from animals?

--Advantages of Bacterial Fermentation

The fermentation method provides several advantages.

- Better customisation: One significant advantage is the ability to adjust the Natriumhyaluronat product to specified requirements. By modifying fermentation conditions, such as pH, temperature and nutrient composition, the molecular weight and viscosity can be tailored to precise specifications.

- Increased efficiency: Bacterial fermentation utilises nutrients effectively, thereby reducing production costs. The method also yields higher extraction rates, as cellulases and other enzymes facilitate cell disruption and HA extraction.

- Enhanced purity: The resulting Natriumhyaluronat exhibits a high level of purity. Smaller molecules, such as polypeptides and polysaccharides in nanometre sizes, are produced and are easily absorbed.

- Environmentally ethical: This production process provides a reliable supply of Natriumhyaluronat. Unlike animal-derived sources, no animals are used, thereby observing ethical and sustainable practices.

Further reading: How is the HA content analysed in the fermentation broth?

Extraction from Rooster Combs

--The Extraction Process

Rooster combs are another natural source for Natriumhyaluronat. The combs contain connective tissue with a high concentration of the substance.

This extraction method was initially applied for laboratory investigations. It was subsequently abandoned due to a low extraction yield, high costs and procedural complexity.

--Disadvantages of Extraction from Animal Tissues

Extracting Natriumhyaluronat from rooster combs yields a relatively high output. The combs are readily available and can be harvested without causing harm to the rooster.

However, this preparation method has several disadvantages.

- A primary concern is the potential transmission of diseases, such as Avian influenza, from the animal to humans.

- Another disadvantage is the degradation of Natriumhyaluronat. Enzymes present in animal tissues may break down the polymer chains during extraction.

- Furthermore, the use of animal-derived Natriumhyaluronat is inappropriate for individuals with specific dietary requirements, such as vegans and vegetarians.

Conclusion

In conclusion, both bacterial fermentation and extraction from rooster combs offer distinct advantages and disadvantages. The choice of production method depends on the product’s requirements and the manufacturer’s ethical considerations. By selecting an appropriate source and adjusting the production process, healthcare professionals and consumers can benefit from the effective properties of this polysaccharide.

Stanford Advanced Materials (SAM) supplies high-purity Natriumhyaluronat in the USA. A range of Natriumhyaluronat is available in medical, cosmetic, food and injection grades. The product is produced without animal testing, and is both vegan and kosher. Please contact us if you require further details.

Reference:

[1] Carmen G. Boeriu, Jan Springer, Floor K. Kooy, Lambertus A. M. van den Broek, Gerrit Eggink, "Production Methods for Hyaluronan", International Journal of Carbohydrate Chemistry, vol. 2013, Article ID 624967, 14 pages, 2013. https://doi.org/10.1155/2013/624967

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento