Tantalum Metal Foam: An In-Depth Guide

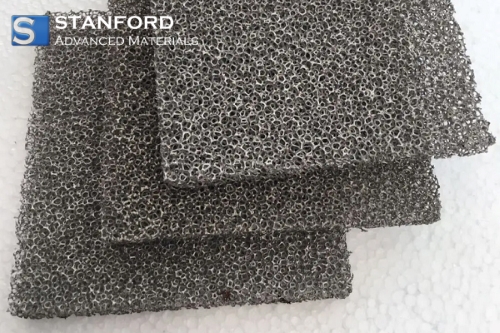

Introduction to Tantalum Metal Foam

Tantal (Ta) is a rare metal. It is hard and bluish‐grey. It has a melting point of approximately 3 017°C, displays high ductility and exhibits significant corrosion resistance against acids. These measured properties are employed in the electronics, aerospace and chemical industries.

Tantalum metal foam is a porous material produced from tantalum. This material merges the physical properties of tantalum with a porous structure that provides a high surface area, low density and enhanced mechanical characteristics. It is used in medical implants, heat exchangers, filtration systems, catalysts and energy storage devices.

This article discusses its features, applications and alternatives. Our aim is to present a clearer technical understanding.

Properties of Tantalum Metal Foam

Tantalum metal foam retains the intrinsic properties of tantalum. The measured key attributes are detailed below:

- Corrosion resistance: Tantalum metal foam retains the high corrosion resistance of tantalum. It is used in chemically corrosive environments where alternative materials may degrade.

- Biocompatibility: Tantalum is biocompatible and non-toxic. This quality renders tantalum metal foam suitable for medical implants. Its compatibility with human tissue ensures that adverse reactions do not occur.

- Thermal conductivity: Despite its porous structure, tantalum metal foam has adequate thermal conductivity. This allows efficient heat transfer, which is beneficial in applications requiring rapid heat dissipation.

- Mechanical strength: The foam structure provides a high strength-to-weight ratio. This attribute is beneficial when reduction in weight is necessary without compromising load-bearing capability.

- Large surface area: The porous matrix increases the available surface area. This improvement is quantifiable in catalytic processes and filtration, where more active sites support enhanced performance.

Manufacturing Methods

Various advanced methods are used to manufacture these metal foams, each enabling precise control over material characteristics.

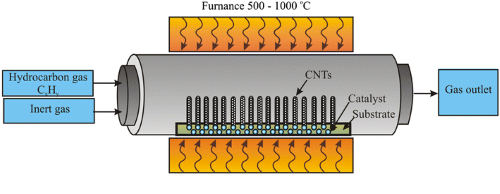

- Chemical vapour deposition (CVD):

In the CVD process, tantalum is deposited in a controlled environment on a substrate; a foam structure is thereby formed. This method permits precise control over parameters such as porosity and density.

[1]

[1]

- Powder Metallurgy:

In powder metallurgy, tantalum powder is compacted and sintered to produce a porous structure. This technique is versatile and enables production of tantalum metal foam with varying porosities and mechanical properties.

- Electrochemical Deposition:

In electrochemical deposition, tantalum is electrodeposited onto a scaffold. The scaffold is subsequently removed, leaving a foam structure. With this method, complex and uniform foam structures are produced.

Applications of Tantalum Metal Foam

Owing to its measured properties, tantalum metal foam is used in several advanced applications across various sectors. Its biocompatibility, extensive surface area, thermal conductivity and corrosion resistance offer benefits in the following areas:

- Medical Implants:

Tantalum metal foam is employed in medical implants such as bone and dental implants due to its biocompatibility. Its porous structure facilitates osseointegration, that is, the integration of bone with the implant, which improves stability and longevity.

- Catalysts:

The high surface area supports its use as a catalyst support. It can increase the efficiency of catalytic reactions within chemical processes.

- Heat Exchangers:

Owing to its adequate thermal conductivity and corrosion resistance, tantalum foam is appropriate for heat exchangers in chemically aggressive conditions found in processing plants.

- Filtration:

The porous structure enables efficient filtration of gases and liquids. It is utilised in processes that require high purity filtrates or where corrosion resistance is critical.

- Energy Storage:

Tantalum metal foam is employed in battery and supercapacitor electrodes. Its large surface area allows a faster ion exchange, thereby increasing both energy storage capacity and charge speed.

Alternatives to Tantalum Metal Foam

1. Titanium Foam

Titanium foam is recognised for its corrosion resistance, particularly in saline environments. This property renders it appropriate for maritime applications and medical implants. Titanium is biocompatible and is frequently used in biomedical implants, as it integrates with human tissue without eliciting adverse reactions. Its relatively lower weight compared with tantalum benefits aerospace applications that demand weight reduction.

Furthermore, titanium foam exhibits quantifiable mechanical strength. It is used in structural applications; however, its thermal conductivity is lower than that of tantalum. Consequently, its use in applications requiring high rates of heat dissipation is limited.

1. Aluminium Foam

Aluminium foam is significantly lighter than tantalum. Its low density renders it appropriate for the automotive and aerospace sectors, where reduced mass contributes to improved efficiency. Aluminium is also more cost-effective compared with tantalum in large-scale applications. Although aluminium foam provides adequate thermal conductivity, it is not rated for use in environments with extreme temperatures or severe corrosive conditions. Its structural and impact absorption properties serve well in automotive and construction industries.

2. Nickel-based Foams

Nickel-based foams possess high temperature resistance. They are used in aerospace and energy sectors. These foams provide measurable corrosion resistance, though in certain chemical environments their performance is lower than that of tantalum. Their electrical conductivity makes them suitable for use in batteries and fuel cells. Nickel is generally less expensive though heavier than tantalum; given that weight is critical in some applications, this factor may restrict its use. The combination of high temperature resistance and electrical conductivity renders these foams versatile in various industrial settings.

3) Foam Made from Stainless Steel

Stainless steel foam delivers adequate corrosion resistance, particularly in less aggressive environments relative to tantalum. Its high mechanical strength makes it appropriate for load-bearing applications in the automotive, aerospace and architectural sectors. Stainless steel is more cost-efficient compared with tantalum when budget constraints apply. Although its thermal conductivity is moderate and lower than that of tantalum, it remains sufficient for many applications. Its versatility allows its use in structural components, filters and heat exchangers. The choice between tantalum metal foam and its alternatives depends on specific requirements that include mechanical strength, thermal properties, weight and cost. Tantalum remains the preferred material for specialised applications that require its precise attributes.

Conclusion

Tantalum metal foam displays properties including corrosion resistance, biocompatibility, thermal conductivity and mechanical strength. These measured attributes support its use in biomedical implants, chemical processing, heat exchangers, filtration systems, catalysts and energy storage applications.

The outlook for tantalum metal foam is promising. Research is focused on improving manufacturing methods to reduce costs and increase production efficiency. Further investigations into tantalum metal foam will yield additional technical data for advanced applications. For further information, please visit Stanford Advanced Materials (SAM).

Referenz:

[1] Zaytseva, Olga & Neumann, Günter. (2016). Carbon nanomaterials: Herstellung, Auswirkungen auf die Pflanzenentwicklung, landwirtschaftliche und ökologische Anwendungen. Chemical and Biological Technologies in Agriculture. 3. 10.1186/s40538-016-0070-8.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento