The Ultimate Guide To Crystal Materials

Crystals enable the conversion and interaction of electricity, magnetism, light, sound and mechanical force. They are essential materials in modern scientific and technological development.

Owing to the rapid progress in solid‐state microelectronics, there is a significant demand for a variety of crystal materials. These include semiconductor crystals, laser crystals, scintillation crystals, optical crystals, superhard crystals, insulating crystals and piezoelectric crystals. Crystal materials are at the forefront of materials science and are linked with sectors such as aerospace, electronics, laser systems, alternative energies and biomedicine. The diversity of crystal types and their applications is extensive.

This article briefly presents several common crystal materials and their practical applications.

Semiconductor Crystals

Semiconductor crystals are the primary fundamental material for the semiconductor industry. They hold a leading position in usage and significance.

In the 1950s, semiconductor technology commenced with germanium single crystals and silicon single crystals. These materials were used to produce diodes, transistors, field-effect tubes, silicon controllers and power tubes. The integration advanced from a few dozen units to thousands in large-scale integrated circuits, which improved reliability and reduced costs. Consequently, these developments facilitated their use in aerospace research, military electronics and civilian devices.

Second-generation semiconductor materials are compound semiconductors. Gallium arsenide (GaAs), indium antimonide (InSb) and indium phosphide (InP) are used for high-frequency, high-speed and high-power electronics in satellite, mobile and optical communications. Given that these materials are scarce, must be synthesised and incur higher production costs, they are gradually being replaced by third-generation materials.

Third-generation semiconductor materials consist of wide bandgap types such as silicon carbide (SiC), gallium nitride (GaN), zinc oxide (ZnO), diamond and aluminium nitride (AlN). They exhibit bandgaps greater than 2.2 eV, high critical electric fields, high thermal conductivity, high electron saturation velocities and enhanced radiation resistance. These characteristics render them more suitable for devices operating at high temperatures and frequencies.

Optical Crystals

Optical crystals are employed as components in optical systems. Examples include lithium halide crystal fluorides, calcium fluoride, magnesium fluoride and barium fluoride. They offer good transmission in both the ultraviolet and infrared ranges. Consequently, they are used in ultraviolet excimer lasers, select infrared laser windows, lenses, prisms and waveplates. Oxide crystals such as sapphire (Al2O3) and yttrium vanadate (YVO4) are also used in related laser components.

Laser Crystals

Lasers generate a highly collimated, monochromatic beam through defined optical resonators. Devices that produce laser light are termed lasers. Solid-state lasers are of considerable technical interest. Laser crystals are materials that convert external energy into laser light via an optical resonant cavity. They form the active medium in solid-state laser systems. Common laser crystals include Nd:YAG, Nd:YVO4, Nd:YLF, titanium-sapphire and ruby.

Scintillation Crystals

Scintillation crystals convert the kinetic energy of high-energy particles into light. These crystals emit fluorescence when struck by such particles. They are utilised for detecting X-rays, γ-rays, neutrons and other high-energy particles. Detection and imaging systems based on scintillation crystals are used in nuclear medicine, high-energy physics, security inspection, industrial non-destructive testing, space physics and nuclear exploration. The crystals are generally produced by synthetic methods. Common examples are BGO (bismuth germanate), CsI (cesium iodide) and PbWO4 (lead tungstate).

Superhard Crystals

Diamond is a natural mineral and the hardest known material. It is a single crystal of carbon formed under high pressure and temperature over extended periods in the Earth. Natural diamond yield is low; typically, 1 carat of crushed diamond is obtained from 4 cubic metres of ore, and large, flawless diamonds are very rare.

Synthetic diamond production has been studied since the 1950s using high-temperature, high-pressure (HTHP) techniques and chemical vapour deposition (CVD). In abrasive operations, when diamond is used to machine hard materials such as steel or sintered silicon carbide, the surface temperature of diamond may reach between 1 500 and 2 000 °C. Under these conditions, the hardness of diamond decreases quickly and oxidation occurs, resulting in graphitic material. Consequently, cubic boron nitride (CBN) was synthesised. CBN exhibits a crystal structure similar to diamond with slightly lower hardness but higher thermal stability. Its use in abrasives enables machining of hard materials with improved process control and chemical inertness. The choice between diamond and CBN depends on the specific application requirements.

Piezoelectric Crystal Materials

When crystals are subjected to mechanical force, they develop polarisation and surface charges; this is known as the positive piezoelectric effect. Conversely, when an electric field is applied, the crystal deforms. Only crystals without a centre of symmetry demonstrate the piezoelectric effect. The first piezoelectric crystal discovered was α-SiO2, which exhibits stable frequency behaviour. It is an appropriate material for manufacturing resonators, filters, transducers, optical deflectors, surface wave devices and various temperature, gas, light and chemical sensors. It is also used in devices such as quartz watches, electronic clocks, colour televisions, stereos and cassette recorders.

Recent developments have produced new piezoelectric crystals such as lithium niobate (LiNbO3) and potassium niobate (KNbO3) with chalcogenide structures. Their piezoelectric properties are applied in instruments in both military and civilian industries. These include blood pressure monitors, piezoelectric keyboards, delay lines, oscillators, ultrasonic transducers and piezoelectric transformers.

Insulating Crystals

A typical example of an insulating sheet is mica. Mica refers to phyllosilicate minerals that are electrically insulating, transparent, heat resistant, corrosion resistant, easily exfoliated and flexible. They are used in electric motors, household appliances, electronics, radios and other devices, thereby playing an important role in the economy and national defence. Although many types of natural mica exist, the industry primarily uses muscovite, followed by biotite.

Synthetic mica possesses excellent properties regarding purity, transparency, high-temperature resistance, corrosion resistance and electrical insulation. It is used as a single-crystal film in the following applications:

① Insulating frames in various vacuum devices, for example in gas pedals, ionisation chambers, magnetrons and electron tubes;

② Window materials, such as output windows for microwave tubes, viewing windows for high-temperature furnaces and acid- and alkali-resistant windows;

③ High-pressure boiler water level gauges in thermal power plants;

④ High-temperature-resistant capacitors, platinum wire surface thermometers and similar components.

Conclusion

Stanford Advanced Materials manufactures functional crystal materials for numerous applications. These materials include magneto-optical crystals such as TGG and TSAG; piezoelectric crystals such as LT (LiTaO3) and LN (LiNbO3); lanthanoid gallium silicate (LGS); scintillation crystals like Ce:LUAG and Ce:GAGG; laser crystal Nd:YAG and epitaxial single-crystal substrates such as GGG, SGGG and LaAlO3.

Crystal materials are used in devices including electrical and optical Q-switches, optical isolators and optical rotators. Optical isolators, including Faraday and fibre isolators, operate over wavelengths ranging from 450 nm to 1 100 nm.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

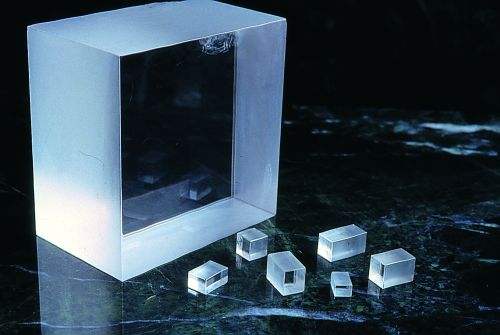

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento