Thermocouple Wire Explained: Principle, Parts, Types, And Selection

What is Thermocouple Wire?

A thermocouple wire is a temperature sensor formed by joining two dissimilar metals. When heated or cooled, the metals generate a small voltage. This voltage is produced due to the thermoelectric effect and is directly related to the temperature difference between the two junctions. The generated voltage is measured and converted into a temperature reading.

Thermocouple wires are used in industrial, scientific and commercial applications where precise temperature monitoring is required. They are common in processes that demand strict temperature control, for example in ovens or engines. Depending on the temperature range and the specific requirements of an application, different types of thermocouples are employed, a subject explained in more detail later.

Operating Principle of Thermocouple Wires

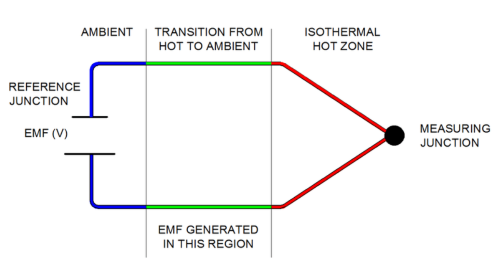

Thermocouple wires operate based on the Seebeck effect. This effect produces a voltage when two dissimilar metals are connected and subjected to different temperatures. The procedure is divided into four steps:

- Hot and Cold Junctions: One junction is placed at the measurement point (the hot junction) and the other is maintained at a known reference temperature (the cold or reference junction).

- Voltage Generation: The temperature difference between the two junctions results in a small voltage that is proportional to that difference.

- Voltage Measurement: The voltage is measured by an instrument such as a voltmeter or a dedicated thermocouple measuring device. Based on the measured voltage, the temperature at the hot junction is calculated.

- Output: The voltage, which varies according to the type of metals used, is utilised to determine the temperature at the hot junction.

[1]

[1]

Further reading: Positive or Negative? A Guide for Beginners to Thermocouple Wire Identification

Components of a Thermocouple Wire

A typical thermocouple wire consists of several principal components:

- Conductive Wires: The wires are manufactured from two different metals chosen for their thermoelectric properties. Common materials include:

- Copper (used in Type T thermocouples)

- Nickel-Chromium and Nickel-Aluminium (used in Type K thermocouples)

- Platinum and Rhodium (used in Type R, S and B thermocouples)

- Junctions: The thermocouple circuit comprises two junctions:

- Hot Junction: The measurement end at which the temperature is determined.

- Cold Junction (or Reference Junction): The end maintained at a known reference temperature.

- Insulation: The wires are often coated with materials such as glass fibre, Teflon or ceramic to prevent short-circuits. The insulation also maintains measurement accuracy by preventing electrical contact between the wires.

- Protective Sheath: Some thermocouple wires are fitted with a protective sheath made from materials such as stainless steel. This sheathing protects the wires from physical damage and chemical exposure, thereby maintaining their integrity in demanding environments.

Types of Thermocouples

Thermocouple wires are designed specifically for the thermocouple type with which they are employed. Each type utilises a unique combination of metals and operates over a specific temperature range. The common types are:

- Type K (Chromel-Alumel): This is the most widely used thermocouple type. It operates over a temperature range from -270°C to 1372°C and is employed in many industrial applications.

- Type J (Iron-Constantan): Type J thermocouples are suitable for temperatures from -40°C to 750°C. They are typically used for general temperature measurements.

- Type T (Copper-Constantan): These thermocouples are ideal for low-temperature measurements, operating from -200°C to 350°C. They are employed in cryogenics and the food industry.

- Type R (Platinum-Rhodium): Type R thermocouples are used for high-temperature measurements, generally between 0°C and 1600°C. They are used in scientific applications where precise measurement is required.

- Type S (Platinum-Rhodium): These thermocouples are similar to Type R with different proportions of platinum and rhodium. They are used in laboratory settings for high precision measurements.

- Type B (Platinum-Rhodium): Type B thermocouples are designed to operate at very high temperatures, up to 1700°C. Type B is applied in industrial high-temperature applications, for example in furnace monitoring.

- Type E (Chromel-Constantan): These thermocouples deliver a reliable output for low temperatures and operate from -200°C to 900°C.

- Type N (Nicrosil-Nisil): This type offers enhanced stability and oxidation resistance. It operates from -200°C to 1300°C and is used in precise industrial applications.

Selecting Thermocouple Wire

When purchasing thermocouple wire, it is important to select the correct type for the intended application. Whether the application is industrial, in research or in a laboratory, the correct thermocouple wire ensures accurate temperature measurements.

- Temperature Range: Ensure that the thermocouple wire meets the required temperature range.

- Material: Choose a wire made from materials appropriate for the operating environment. For high-temperature conditions, a Type K or Type S thermocouple may be required.

- Insulation and Sheathing: Select suitable insulation and protective sheathing based on the environmental conditions, such as exposure to chemicals, high humidity or extreme temperatures.

- Measurement Accuracy: Verify that the thermocouple wire fulfils the precision requirements of the application.

By selecting a thermocouple wire that meets the specific requirements of an application, accurate temperature measurements can be achieved in each environment. Stanford Advanced Materials (SAM) offers a range of thermocouple wires, including wires made from Platinum-Rhodium (Pt-Rh), Type J, Type K and tungsten-rhenium alloys. Detailed specifications and further information are available in our complete product catalogue.

Reference:

[1] Litteaur, Raymond. (2018). In Situ Verification Techniques for Multipoint Thermocouples in Pressure Vessels. 10.13140/RG.2.2.20703.30885.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento