Case Study: Elevating Aerospace Excellence With Titanium 6242 Alloy

Aerospace Industry Challenge

The aerospace industry must obtain a balance between structural integrity, fuel efficiency and overall weight. Conventional materials do not satisfy these requirements, which has led researchers to investigate advanced alloy options. In recent years, titanium alloys have assumed increased importance due to their specific properties.

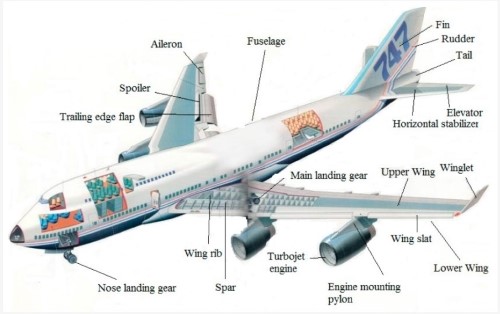

Figure 1. Aircraft Components

The Titanium 6242 Alloy for Aerospace Applications

Titan 6242 has been identified as a viable candidate for aerospace applications. Titanium 6242 (TI-6Al-2Sn-4Zr-2Mo-Si) is a medium-strength titanium alloy incorporating aluminium. It offers a notable strength-to-weight ratio and corrosion resistance. The alloy exhibits high strength, fatigue resistance and damage tolerance, thereby making it suitable for load-bearing structures in aircraft. Its corrosion resistance further ensures extended durability under harsh conditions.

Figure 2. Titanium 6242 Alloy

Owing to these attributes, Titan 6242 is applied in numerous aerospace components.

- Aircraft components: Titan 6242 is used in manufacturing critical components such as landing gear, wing structures, fuselage sections and engine parts. Its high strength-to-weight ratio and fatigue resistance help maintain the structural integrity of the aircraft.

- Aerospace fasteners: The alloy is employed in the production of fasteners, including bolts, screws and nuts. These fasteners secure the assembly of components under extreme operating conditions.

- Engine parts: Titan 6242 is utilised in engine construction. It withstands elevated temperatures and resists corrosion. Consequently, its use contributes to improved engine efficiency and reduces fuel consumption and emissions.

- Aerospace propellers: The alloy is applied in the manufacture of propellers for manned and unmanned aerial vehicles. Its lightweight and high strength properties enhance propeller performance and fuel efficiency.

- Structural elements: Throughout the aircraft, Titan 6242 is used in items such as bulkheads, frames and beams. Its strength and corrosion resistance contribute to the overall integrity and durability of the structure.

- Aerospace springs: The alloy is used in manufacturing springs for aerospace systems. Its high strength facilitates precise energy storage and release in critical applications.

Further reading: Titanium in the Aerospace Industry

The Results

Overall, the use of the titanium alloy Titan 6242 in aerospace applications is significant. The combination of high strength, corrosion resistance and fatigue properties permits the development of solutions that maintain structural performance while reducing weight. Manufacturers continue to evaluate new material options; Titan 6242 remains a primary option for many aerospace applications.

Stanford Advanced Materials (SAM) supplies titanium alloys with a defined purity and customisable material properties. Customised forms and component ratios are available. If interested, please submit an enquiry.

Reference:

[1] Gloria, A.; Montanari, R.; Richetta, M.; Varone, A. Alloys for Aeronautic Applications: State of the Art and Perspectives. Metals 2019, 9, 662. https://doi.org/10.3390/met9060662

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

.jpg)

Chin Trento

Chin Trento