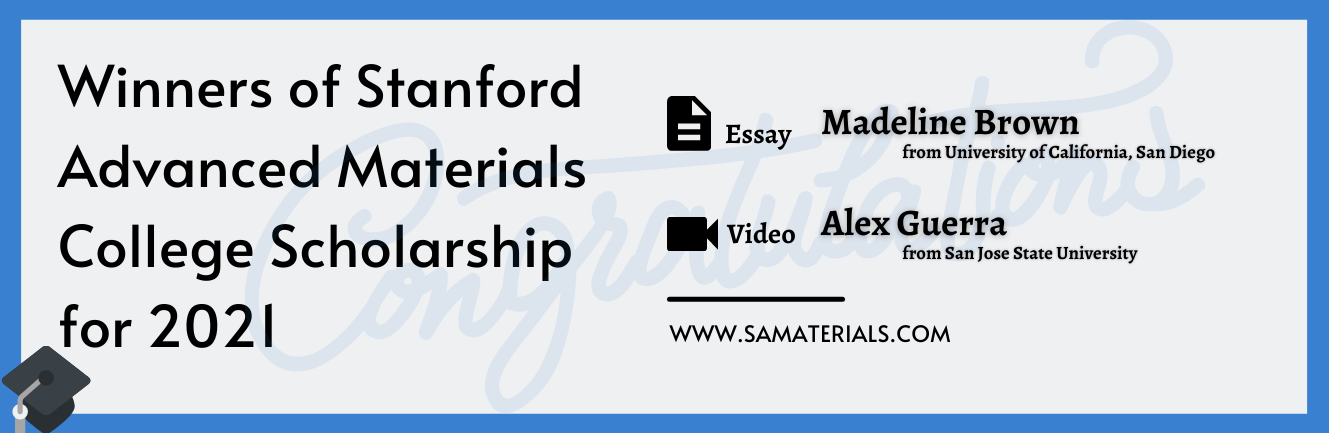

Winners Of Stanford Advanced Materials College Scholarship For 2021

The SAM-College Scholarship 2021 examines the effects of emerging technologies and new materials on modern society. Advanced materials offer improved performance; however, various technical problems persist. Consequently, SAM requested candidates to identify which technical problem may present the greatest challenge over the next decade. They were also asked to detail previous projects in which a technical issue was resolved using advanced materials.

In recent months, approximately 150 essays and 20 videos were received. All candidates submitted work that met the required standard, and we expect that their future efforts will generate valid scientific outcomes.

From these submissions, two winners were selected.

Madeline Brown

from the University of California, San Diego

Thank-you letter from Madeline Brown

Alex Guerra

from San Jose State University

Thank-you letter from Alex Guerra

Here are their submissions.

Essay – Madeline Brown

The Decline of the Scalpel: A Perspective on the Future of Surgery

Surgical practice has evolved over time, yet the method of making incisions remains standard. Modern procedures involve making incisions that expose the body to antibiotic‐resistant microbes. Each incision produces scar tissue and necessitates further care.

My interest in improving surgical methods began when my mother required a heart valve replacement. The operation was performed by making a small incision in her right forearm that provided access via an artery to the affected valve. After the procedure, my sibling and I stayed with her in the recovery area. I noted that she experienced persistent pain at the incision site. Daily cleaning and dressing changes were mandatory to prevent infection and manage scar tissue.

This prolonged discomfort prompted me to develop a method intended to minimise scar formation before tissue damage occurs. The method aims to obviate the need for conventional incisions.

The proposed solution comprises a drug delivery device made from porous silicon particles and a polymer matrix. The porous silicon particles are adjusted to incorporate specific pharmaceuticals, while the polymer restricts the particles to the designated site. For example, if a patient suffers an ischaemic stroke, porous silicon particles loaded with t-PA are guided through the bloodstream to the clot. The drug is delivered at an isolated target, thereby achieving effective action. Given that precision is required, porous silicon particles are produced using electrochemical etching. Subsequently, the particles are combined with polycaprolactone (PCL), an FDA-approved polymer that encapsulates the silicon nanoparticles. The polymer solution and drug-laden particles are mixed and sprayed with an airbrush. This process produces oriented fibres that form a patch. The patch can then be trimmed and inserted into the body via a trocar, thereby reducing injury associated with a large incision.

More complex procedures may require different combinations of particles and polymers. Each combination will require its own testing protocol. Collectively, these methods may reduce the risk of antibiotic-resistant infections and limit the accumulation of scar tissue.

Medical progress depends on recognising procedural limitations, regardless of their perceived scale. Given that current surgical methods sometimes cause additional patient discomfort, it is essential to reduce incision-related impact. Adopting minimally invasive techniques supports the commitment to "primum non nocere".

References

[1] Zuidema, J. M., Dumont, C. M., Wang, J., Batchelor, W. M., Lu, Y.-S., Kang, J., Bertucci, A., Ziebarth, N. M., Shea, L. D., Sailor, M. J., Porous Silicon Nanoparticles Embedded in Poly(lactic-co-glycolic acid) Nanofiber Scaffolds Deliver Neurotrophic Payloads to Enhance Neuronal Growth. Adv. Funct. Mater. 2020, 30, 2002560. https://doi.org/10.1002/adfm.202002560

[2] Qin, Z., Joo, J., Gu, L. and Sailor, M.J. (2014), Size Control of Porous Silicon Nanoparticles by Electrochemical Perforation Etching. Part. Part. Syst. Charact. 31: 252-256. https://doi.org/10.1002/ppsc.201300244

[3] Zuidema, J. M., Kumeria, T., Kim, D., Kang, J., Wang, J., Hollett, G., Zhang, X., Roberts, D. S., Chan, N., Dowling, C., Blanco-Suarez, E., Allen, N. J., Tuszynski, M. H., Sailor, M. J., Adv. Mater. 2018, 30, 1706785. https://doi.org/10.1002/adma.201706785

Video – Alex Guerra

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento