Zinc-Aluminium Alloy Wire For Anti-Corrosion Applications

Introduction

Zinc–aluminium alloy wire (Zn–Al) is a material used in thermal spraying for corrosion protection. It is applied in various industrial processes.

This article details the composition, properties, manufacturing procedures and specific applications of zinc–aluminium alloy wires. The focus is on the wire’s role in corrosion protection through thermal spraying.

Composition and Properties

Zinc–aluminium alloys typically use zinc as a base metal with an aluminium content ranging from 5 % to 55 %. The composition is adjusted to meet application specifications. Standard formulations include Zn–5Al, Zn–10Al and Zn–22Al.

The addition of aluminium alters the alloy properties, balancing tensile strength, ductility and corrosion resistance.

The principal properties of zinc–aluminium alloy wire are outlined below:

- Corrosion resistance: Aluminium forms a protective oxide layer on the surface, thereby improving resistance to corrosive environments. This property is beneficial in outdoor and chemically aggressive conditions.

- Mechanical strength: The alloy exhibits sufficient tensile strength and hardness. It can withstand mechanical loads and deformation during service.

- Thermal conductivity: Zinc–aluminium alloys offer effective heat transfer. This facilitates efficient cooling in applications such as electrical components and heat exchangers.

- Electrical conductivity: Although its conductivity is lower than that of pure copper or aluminium, Zn–Al alloys deliver adequate electrical performance for selected uses.

- Workability: The wire is amenable to drawing, rolling and forming into various dimensions. This enables its use in different manufacturing procedures.

Manufacturing Procedures

The production of zinc–aluminium alloy wire involves several steps:

- Melting and alloying: The primary metals, zinc and aluminium, are melted together in a controlled ratio. The process is monitored to ensure uniform composition and to avoid contamination.

- Casting: The molten alloy is poured into billets or rods. Continuous casting methods are often used to standardise the material properties.

- Hot rolling: The billets are heated to a set temperature and passed through a series of rolls. This reduces the cross-sectional area and improves mechanical characteristics.

- Drawing: The rolled billets are drawn through dies to attain the required wire diameter. This step enhances both the tensile strength and the surface finish.

- Annealing: The wire is heat treated to reduce internal stress and to improve ductility. Annealing may be carried out at various stages to meet defined material characteristics.

- Coating and finishing: The wire may be coated with zinc or other protective layers. This procedure further increases corrosion resistance and improves the surface quality.

Important Applications in Corrosion Protection

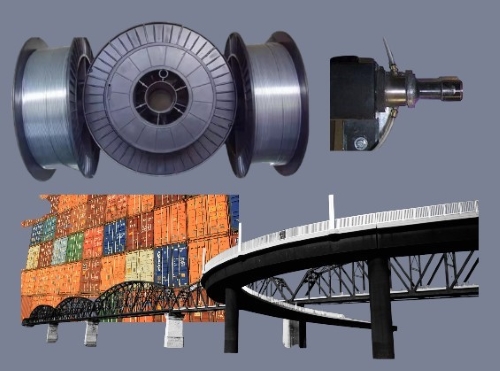

Zinc–aluminium alloy wires are used in several areas for thermal spraying as a means of corrosion protection:

1. Thermal Spraying for Corrosion Protection:

The Zn–Al wire is melted and sprayed onto component surfaces. This method is implemented in shipping, oil and gas, and infrastructure industries. The coating acts as a barrier against corrosion and extends the service life of the substrate.

2. Containers and Storage Tanks:

Both the interior and exterior surfaces of storage containers and tanks are coated with a Zn–Al alloy. This protects against chemical exposure and environmental factors. Industries such as petrochemicals, food processing and water treatment utilise this application.

3. Bridges and Superstructures:

Structures such as bridges and superstructures are exposed to severe weather conditions. Thermal sprayed Zn–Al coatings are applied to maintain structural integrity. This is particularly important in coastal and industrial regions where corrosion rates are high.

4. Electrical Iron Towers, Masts and Towers:

Electrical infrastructure, including iron towers and masts, receives Zn–Al coatings. The coating reduces maintenance needs and supports structural safety in power distribution networks.

5. Capacitors and Metal Brackets:

In the electronics sector, Zn–Al wire is used to coat capacitors and metal brackets. This treatment reduces corrosion and prolongs component lifespans. It supports the reliable operation of electronic systems.

6. Ductile Cast Iron Pipes:

Pipes used in water supply and wastewater systems are often coated with a Zn–Al alloy. The coating protects against corrosion from water and wastewater. This ensures the long-term function of piping networks.

7. Traffic Equipment:

Traffic equipment such as signs, barriers and railings are subject to environmental exposure. Zn–Al coatings provide a protective barrier against corrosion. This contributes to the longevity of traffic systems and aids in public safety.

Conclusion

The combination of corrosion resistance, mechanical strength and ease of processing makes zinc–aluminium alloy wire a material widely used in manufacturing and construction. Its use in thermal spraying for corrosion protection is well documented.

Industrial advancements continue to influence material demand. Demand for zinc–aluminium alloy wire is expected to increase as applications evolve.

Stanford Advanced Materials (SAM) supplies a range of zinc products. Their portfolio includes various zinc–aluminium alloy wires in different compositions and sizes at competitive prices. Customised products are available to meet specific industrial requirements. Please send an enquiry if you are interested.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento