A Comparison Between Tantalum And Multilayer Ceramic Capacitors

Introduction

Tantalum capacitors (Ta) and multilayer ceramic capacitors (MLCC) are two capacitor types used frequently in electronic applications. Although the technologies and materials used for manufacturing tantalum capacitors and MLCCs differ significantly, their basic functions remain identical. In a role akin to a temporary battery, capacitors maintain a constant direct current voltage by providing stored charge. Capacitors are also used as single–pole filters in bypass circuits. When combined with resistors and inductors, they form higher–order filter circuits.

Although both tantalum and MLCC capacitors operate as storage devices, substantial differences exist from production to usage parameters. Before comparing these differences, it is necessary to review fundamental details about capacitors. The capacitance of a parallel–plate capacitor is calculated using the following equation:

C = εr * ε0 * A / d

C = capacitance (F)

A = overlapping area of the plates (m²)

εr = relative dielectric constant (determined by the material between the plates)

ε0 = electric constant (8,854 * 10⁻¹² F·m⁻¹)

d = distance between the plates (m)

Capacitance is one of the most critical parameters when selecting a capacitor. Given the small separation, extensive plate area and high dielectric constant of Ta₂O₅, tantalum capacitors typically offer a high capacitance per unit volume.

This article compares tantalum capacitors and MLCCs in terms of impedance characteristics, parasitic inductance (ESL), equivalent series resistance (ESR), temperature effects and microphonic phenomena. Comparisons are limited to capacitors with similar capacitance values and dimensions.

Basic Information about Tantalum and MLCC Capacitors

What is a Tantalum Capacitor?

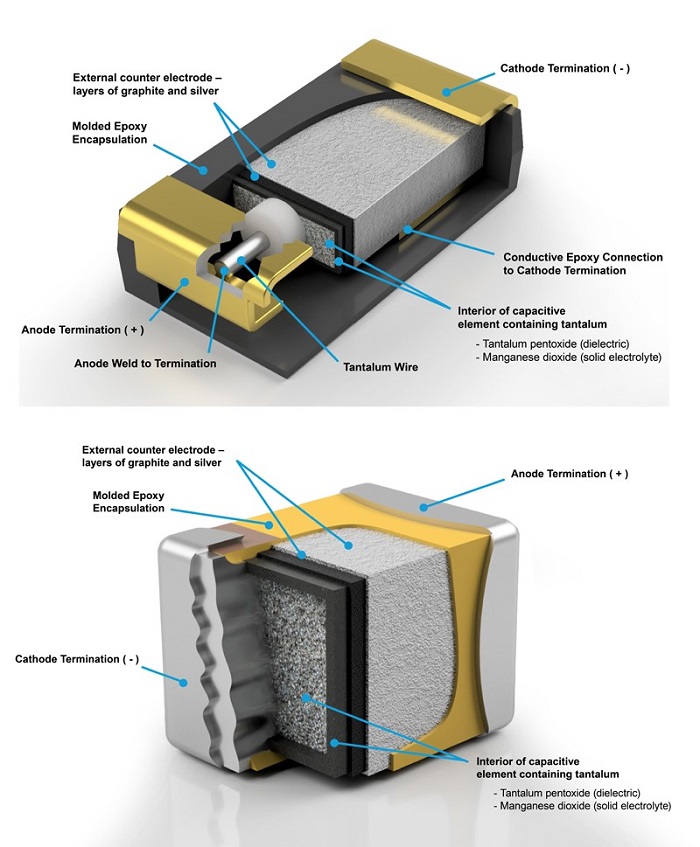

Tantalum capacitors utilise tantalum powder and wires as their primary materials. Tantalum powder is pressed around a tantalum wire to form a pellet that acts as the anode for the capacitor. Because the pellet is porous, it can store a large amount of charge. Consequently, tantalum capacitors exhibit high capacitance per unit volume. A dielectric is formed by the creation of Ta₂O₅ on the anode surface. The final step involves forming a cathode by depositing a MnO₂ layer using Mn(NO₃)₂.

Figure 1a shows a conventional tantalum capacitor with a tantalum wire connecting the anode to the circuit. Figure 1b presents a smaller tantalum capacitor introduced in recent years. Its anode is produced by pressing a tantalum wafer with tantalum powder [2].

Figure 1a & b: A cast tantalum capacitor (top) and a microchip tantalum capacitor (bottom) [2]

What is a Multilayer Ceramic Capacitor?

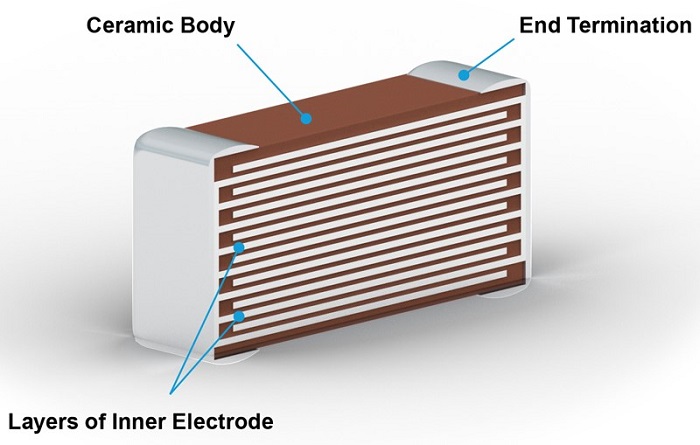

In contrast to tantalum capacitors, ceramic capacitors employ a thicker dielectric layer and smaller plate overlap, resulting in a lower capacitance per unit volume. TiO₂ and BaTiO₃ are the two materials most commonly used in MLCCs. Figure 2 outlines the components of an MLCC.

Figure 2: A multilayer ceramic capacitor [2]

MLCCs are divided into two groups: Class 1 and Class 2. Class 1 ceramic capacitors use materials that are resistant to temperature fluctuations. Consequently, their capacitance does not change significantly between temperatures such as –25℃ and 80℃. Such capacitors are generally manufactured with TiO₂ and exhibit a relatively low εr.

By contrast, Class 2 capacitors are temperature dependent. They are produced using ferroelectric materials such as BaTiO₃, Al₂SiO₅ and MgO:XSiO₂. Although Class 2 capacitors have a relatively high εr, they lack the precision and stability required for some applications.

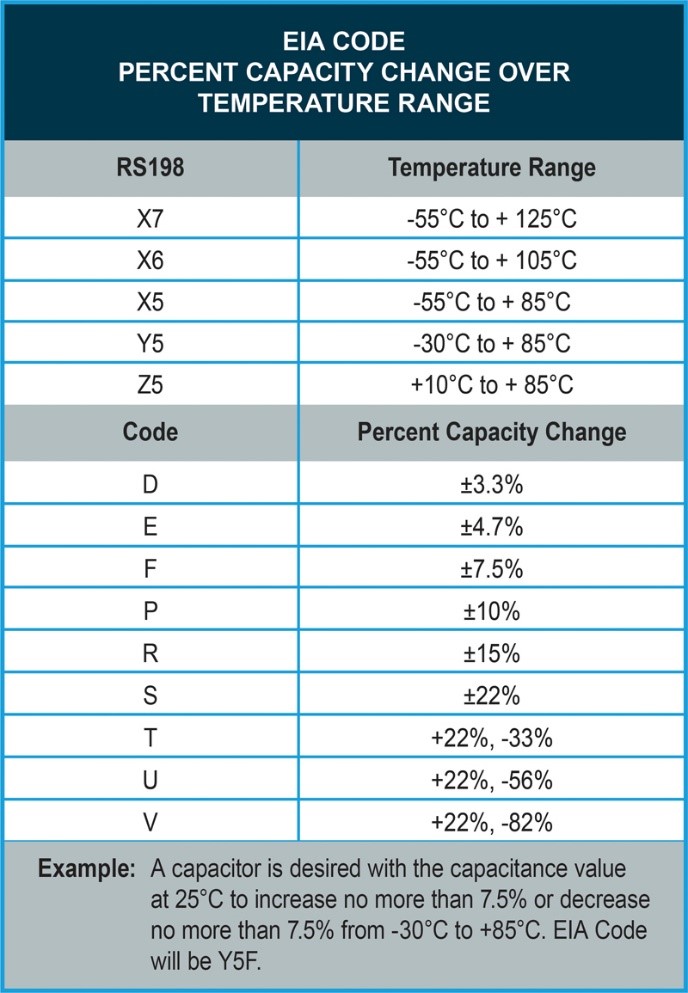

For ceramic capacitors, the EIA code is used to indicate capacitance stability over a given temperature range. Figure 3 details the meaning of each code. For example, X7R specifies that the capacitance may vary by ±15% from –55℃ to 125℃.

Figure 3: EIA Code Table [2]

What is the Difference Between Tantalum Capacitors and MLCCs?

Impedance and Equivalent Series Resistance

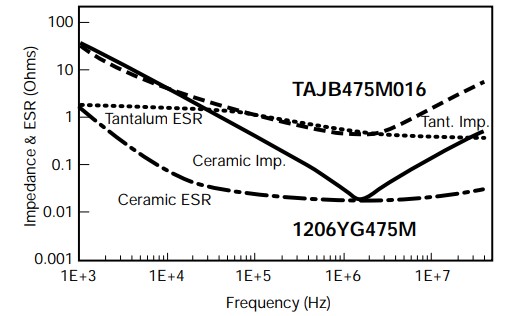

The impedance, parasitic inductance (ESL) and equivalent series resistance (ESR) are key figures for evaluating capacitor performance. ESL and ESR are measured with impedance analysers. Lower ESL and ESR values result in better performance in circuit conditions. Figure 4 illustrates the impedance and ESR of a 4.7µF, Y5V, 16V MLCC and a 4.7µF, 16V tantalum capacitor [1].

Figure 4: Impedance and ESR characteristics for 4.7µF tantalum and ceramic capacitors [1]

At low frequencies the impedance values are equivalent, thereby confirming similar capacitance values. As frequency increases, the ESR of the ceramic capacitor is considerably lower than that of the tantalum capacitor. Both capacitor types exhibit a “V”–shaped impedance curve; initially, the curve declines due to the capacitive effect, and then it rises because of the inductive element. In Figure 4, the ceramic capacitor clearly shows a lower parasitic inductance, largely due to the leadframe design typically used for tantalum capacitors [1].

Temperature Effects

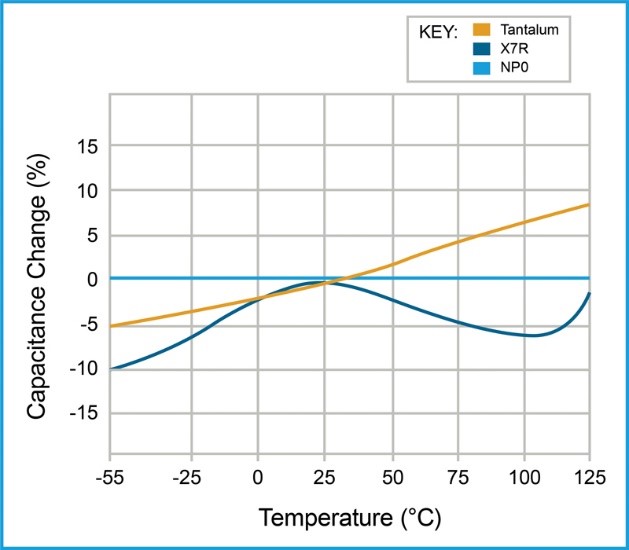

Class 1 ceramic capacitors are minimally affected by temperature changes, whereas Class 2 capacitors are temperature dependent. Figure 5 shows that the capacitance of tantalum capacitors changes in a linear manner with temperature, while the capacitance of Class 2 ceramic capacitors changes irregularly.

Figure 5: Capacitance variation with temperature for tantalum, Class 1 and Class 2 ceramic capacitors [2]

Microphonic Effects

In audio applications, the microphonic or piezoelectric effect is an important considerationpt; padding: 0cm 5.4pt 0cm 5.4pt;" valign="top" width="184">

Price

ü

Stanford Advanced Materials (SAM) provides both tantalum and multilayer ceramic capacitors. Should you require assistance in selecting the appropriate capacitor for your application, please consult our technical staff with your detailed specifications.

References:

Cain, J. (n.d.). Comparison of Ceramic and Tantalum Multilayer Capacitors.

Zedníček, T. (2022, 01/06/2022). The Basics and Benefits of Tantalum and Ceramic Capacitors. Passive Components Blog. Retrieved 11/01/2023, from https://passive-components.eu/the-basics-benefits-of-tantalum-ceramic-capacitors/.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento