Advanced Ceramics In Green Energy Technologies

The world is undergoing a profound transformation towards sustainable energy solutions, driven by the need to combat climate change, reduce greenhouse gas emissions, and transition to renewable sources of power. Among the most promising materials in this transition are advanced ceramics, which offer exceptional properties that make them indispensable in a range of green energy technologies.

1. Solar Energy Systems

The generation of solar energy has become one of the most accepted forms of renewable energy sources around the world. Advanced ceramics have an important role in enhancing the performance capabilities of solar energy cells and solar thermal systems.

- Photovoltaic Cells: Within solar photovoltaic cells, materials such as ceramic coatings help enhance the efficiency and lifespan of solar cells. The use of ceramic films has also been considered as a replacement for silicon materials in solar cells. The films help enhance the rate at which sunlight is absorbed and also work to minimise losses through heat dissipation.

- Solar Thermal Power Plants: In solar thermal power stations, advanced ceramics are employed in heat exchangers and solar absorber tubes. Ceramic materials such as ceramic composites have good resistance to elevated temperatures and harsh environments, thus enhancing the total efficiency of solar thermal power stations.

- Ceramic Coatings for Reflectors: Ceramic reflective coatings are applied to mirrors found in concentrated solar power plants. This technology is used to increase the reflectivity of the mirrors found in concentrated solar power plants.

2. Wind Energy

Wind energy is yet another component that is important in the renewable energy sector. Advances in ceramic materials have played an important part in various aspects of wind turbine components to produce more efficient and durable systems.

- Bearings and Gearboxes: The bearings and gearboxes used in wind turbines are prone to abrasion and mechanical stress. Silicon nitride and zirconia ceramics are used to produce bearings that are more durable and exhibit less friction. The ceramic materials are used to create bearings that are more effective and require less maintenance than before.

- Composites Used in Blades: Ceramic matrix composites are used for wind turbine blades to improve their strength properties. The addition of ceramics to composites enables wind blades to withstand harsh environments and forces of nature, making wind blades more durable.

3. Energy Storage Systems

Energy storage is a critical aspect of green energy systems, especially as intermittent renewable sources like solar and wind energy require efficient storage solutions to balance supply and demand. Advanced ceramics are pivotal in enhancing the performance of energy storage technologies, including batteries, supercapacitors, and flywheels.

- Lithium-ion Batteries: Using advanced ceramic materials in lithium-ion batteries makes them appropriate for use in electric vehicles (EV) and renewable energy storage systems. Ceramics in lithium-ion batteries improve performance by increasing safety, raising energy density, and increasing the lifespan of lithium-ion batteries.

- Solid State Batteries: One of the most promising areas in energy storage technology is the development of solid state batteries, which substitute traditional liquid electrolytes with ceramic materials. Solid state batteries exhibit improved safety and energy density and also enjoy a long lifespan. Solid state batteries of lithium ceramic and sodium ceramic are under development.

- Supercapacitors: Supercapacitors, relying on electrostatic field energy storage, require high-quality ceramics for electrodes and dielectrics in supercapacitors. Advanced ceramics enhance the charge and discharge cycle efficiency and storage capabilities of supercapacitors and make them potential storage devices for renewable energies.

- Flywheels: Flywheels are used for short-term energy storage and stabilisation in power grids. Advanced ceramics are used in flywheel rotors because of their high strength and resistance to wear and thermal shock. Ceramic materials improve the efficiency of flywheels, allowing them to operate at high speeds without degradation.

4. Fuel Cells

Fuel cells are an increasingly popular alternative to traditional combustion engines in transportation and stationary power generation, converting chemical energy directly into electrical energy. Advanced ceramics are central to the development of high-efficiency fuel cells, such as solid oxide fuel cells (SOFCs) and molten carbonate fuel cells (MCFCs).

- Electrolyte Materials: In SOFCs, high-performance ceramics function as the electrolyte material that facilitates the passage of oxygen ions from the anode to the cathode. Yttria-stabilised zirconia (YSZ), a ceramic, is mostly employed due to its high-temperature conductivity properties and stability.

- Anode and Cathode Materials: The anode and cathode in fuel cells are usually made of advanced ceramics. Ceramic composites are also used because they improve fuel cell efficiency by functioning effectively under higher temperatures and higher pressures.

- Durability and Efficiency: The use of modern ceramics in fuel cell components improves both the durability and efficiency levels of fuel cells. Ceramics tolerate extreme heat and corrosive properties associated with fuel cells and are therefore one of the vital materials used in efforts to develop clean energy technology.

5. Geothermal Energy Systems

Geothermal energy systems harness the Earth's natural heat to generate electricity. Advanced ceramics are used in geothermal power plants to enhance the performance of key components, such as turbine blades, heat exchangers, and piping systems.

- High-Temperature Resistance: Ceramics, especially silicon carbide (SiC) and zirconia-based composites, are used in geothermal applications due to their ability to withstand extreme temperatures encountered in geothermal wells. These materials prevent corrosion and degradation, ensuring the longevity and reliability of geothermal energy systems.

- Improved Efficiency: Advanced ceramics also improve the thermal efficiency of geothermal systems by enhancing heat transfer properties in heat exchangers and preventing energy loss in high-temperature environments.

Conclusion

Advanced ceramics are indispensable in the development and optimisation of green energy technologies. Their exceptional thermal, mechanical, and electrical properties make them ideal for use in solar, wind, energy storage, fuel cell, and geothermal energy systems. As the demand for sustainable and efficient energy solutions grows, advanced ceramics will continue to play a pivotal role in shaping the future of green energy. For more advanced ceramics, please check Stanford Advanced Materials (SAM).

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

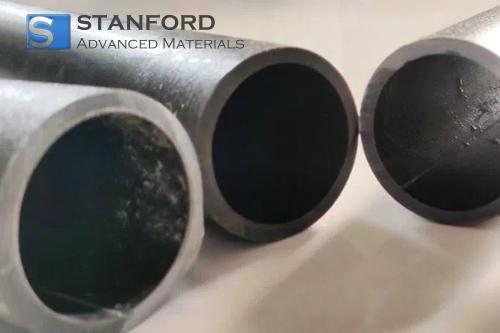

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento