Polylactic Acid and Polyhydroxyalkanoates Pellets

Global Plastic Pollution and the Need for Sustainable Alternatives

Plastic waste fills landfills and pollutes oceans globally. Abandoned plastics are an increasing problem in many countries, harming wildlife and natural habitats.

Recycling provides some benefits but does not fully resolve the issue. In many areas, recycled plastics lose their quality after a few cycles. The widespread use of fossil fuels in plastic production necessitates eco-friendly alternatives. Biodegradable alternatives present a feasible solution. Plastics that can naturally degrade could alleviate the burden on our ecosystem and contribute to cleaner environments.

Biodegradable Plastics: Polylactic Acid and Polyhydroxyalkanoates

Polylactic acid and polyhydroxyalkanoates are two of the most popular biodegradable plastics. They are produced through different natural processes. Polylactic acid is derived from renewable resources such as corn and sugar cane. Polyhydroxyalkanoates are produced via microbial fermentation. Both materials decompose without leaving harmful residues. Their chemical structures allow beneficial organisms or the natural environment to break them down into simpler forms. Most researchers and engineers regard these plastics as suitable replacements for conventional plastics.

Why Polylactic Acid and Polyhydroxyalkanoates Are Considered to be Environmentally Friendly

Polylactic acid decomposes through industrial composting, requiring heat and water to break down into carbon dioxide and water. Polyhydroxyalkanoates are unique in that most forms naturally degrade in soil and water with the aid of common bacteria.

Both plastics have a lower carbon footprint than traditional plastics, made from oil. They utilise renewable raw materials in production, reducing fossil fuel consumption.

Numerous tests indicate that these materials release fewer toxic chemicals once degraded. They do not leave behind hazardous chemicals that could harm local flora or fauna. The ease with which nature can manage these plastics offers hope for a cleaner, waste-free future.

What Happens When these Pellets Come into Contact with Soil, Water, or Microbes

Polylactic acid and polyhydroxyalkanoates pellets decompose upon contact with water, soil, or microbes. Polylactic acid decomposes gradually into lactic acid when exposed to water and the appropriate temperature. For polyhydroxyalkanoates, naturally occurring bacteria play a crucial role. Bacteria secrete enzymes that break down the long polymer chains into shorter segments, which are further decomposed into water and carbon dioxide. This process mimics natural degradation, such as that of plant material. The degradation rate of these pellets depends on environmental conditions. Temperature, moisture, and microbial populations significantly influence the rate of decomposition. Under ideal conditions, some polyhydroxyalkanoates fully degrade within weeks to months, while in cooler or drier areas, the process proceeds more slowly.

Polylactic Acid versus Polyhydroxyalkanoates Comparison

Polylactic acid and polyhydroxyalkanoates share many advantageous qualities; however, they also have notable differences. Polylactic acid requires higher temperatures for effective degradation, performing best in controlled heat and moisture conditions found in industrial composting facilities. Conversely, polyhydroxyalkanoates decompose more naturally, thriving in various conditions, including natural soil and water environments. Mechanical properties also vary; polylactic acid is generally stronger and stiffer, making it suitable for products such as cutlery and packaging, whereas polyhydroxyalkanoates are more flexible, commonly used in medical devices and films. Differences in production costs and processes exist as well, with polylactic acid having reached large-scale production while polyhydroxyalkanoates remain more specialised and occasionally more expensive to manufacture.

Applications and Impact

These biodegradable pellets find application across various sectors. In the food industry, polylactic acid is utilised in disposable cutlery, cups, and containers. The packaging industry capitalises on its strength and clarity. Polyhydroxyalkanoates are highly regarded in the medical field, being manufactured into drug delivery systems, sutures, and wound dressings. Some manufacturers employ them to create agricultural films, providing environmental benefits by reducing soil pollution. Municipalities may encounter fewer waste management challenges through the utilisation of these materials. Generally, products made from these polymers help reduce environmental impact. Empirical tests indicate that substituting fossil fuel plastics with these biodegradable options decreases greenhouse gas emissions. As a growing number of companies adopt sustainable practices, these biodegradable plastics are crucial in promoting a greener economy.

STEM Experiment Idea

A straightforward experiment illustrates the degradation process. Obtain a small quantity of polylactic acid pellets and a matching quantity of polyhydroxyalkanoates pellets. Place each in jars containing moist soil, maintaining a warm constant temperature. Observe any alterations in material consistency over several weeks, noting changes in shape, colour, and weight. Signs such as fragment formation or softening may be evident. A simple test using a pH test kit will also reflect changes as organic acids are generated.

The experiment provides a practical means of observing material breakdown and allows students to comprehend natural processes. It is suitable for school projects or science clubs, reinforcing significant concepts in environmental science and materials engineering.

Conclusion

Biodegradable plastics present a viable alternative in a world inundated with conventional plastic waste. Polylactic acid and polyhydroxyalkanoates are two such benefits in practice. Both are produced from renewable feedstocks and can naturally degrade under proper conditions. They contribute to reduced fossil fuel consumption and diminished strain on our planet. For further information and STEM experiments, please visit Stanford Advanced Materials (SAM).

Frequently Asked Questions

F: What materials are used to produce polylactic acid pellets?

Q: They are derived from renewable plant resources such as corn and sugar cane.

F: How do polyhydroxyalkanoates degrade in the environment?

Q: Natural bacteria secrete enzymes that decompose the polymer into carbon dioxide and water.

F: What are the benefits of these biodegradable plastics?

Q: They reduce fossil fuel consumption, greenhouse gas emissions, and environmental pollution.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

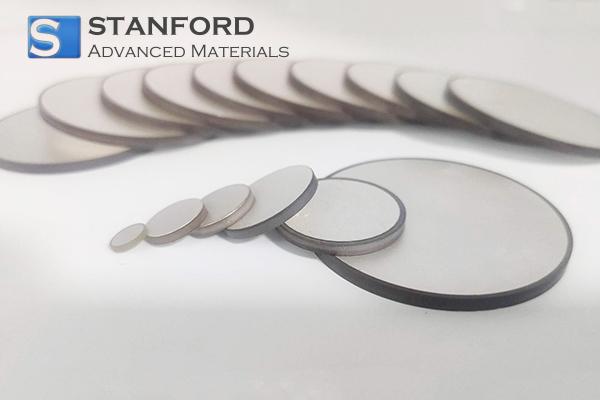

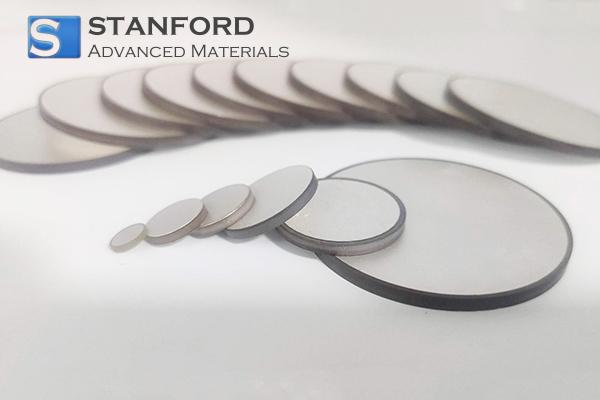

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Dr. Samuel R. Matthews

Dr. Samuel R. Matthews