Heat-Resistant Polymers: Polyethylene Terephthalate and Polyimide Films

Introduction

Heat-resistant polymers are the foundation of modern engineering and electronics. Polyethylene terephthalate films and polyimide films have supported scientists and engineers for decades. These films are highly resilient, exhibit improved heat resistance, and are very lightweight. This article will explore what these films are and their role in protecting electronics.

What Are Polyethylene Terephthalate and Polyimide Films

Polyethylene terephthalate films are produced from a widely used thermoplastic polymer. They are applied in packaging and even flexible displays. Polyethylene terephthalate films can withstand moderate temperatures and possess good mechanical properties. They exhibit a strength-transparency balance.

Polyimide films possess excellent thermal stability. Polyimide films are used in environments where temperatures exceed 400°C. Polyimide films typically serve as flexible printed circuitry or insulation for sensitive components in space vehicles. Their molecular structure confers exceptional heat and chemical resistance.

Both of these materials have existed for decades, with a history of continuous innovation. The difference in their properties arises from their distinct molecular configurations. In summary, polyethylene terephthalate is built from repetitive ester linkages, while polyimide consists of unique imide rings that create stronger linkages, thereby enhancing heat performance. Both polymers are greatly valued by engineers for their unique advantages.

How Polyimide and Polyethylene Terephthalate Films Shield Electronics

Electronic devices generate heat during operation, and even minor temperature increases can affect performance. Polyethylene terephthalate films act as heat-diffusing and insulating layers. In cold applications, these films help prevent short circuits and protect sensitive wiring.

Polyimide films are implemented in more aggressive environments. They serve as heat shields. Polyimide films provide both electrical and thermal insulation within flexible electronics. Polyimide films have a high melting point and can thus withstand extreme conditions. This protection is essential in high-performance equipment and aerospace applications, where malfunctions could result in significant costs or dangers.

The function of these films is evident. They isolate components from heat while allowing adequate signal flow. They also protect against chemical and water exposure. The combined properties make them widely applicable across various industries.

STEM Experiment: Thermal and Electrical Insulation of Polyethylene Terephthalate and Polyimide Films

One of the most effective ways to understand these polymers is through experimentation. By conducting thermal resistance, electrical insulation, and mechanical strength tests, you can observe how each film reacts under stress. These tests facilitate experiential learning and comparison of the two materials.

Physics and Engineering

• Thermal Resistance Test:

Place a sample of each film over a heat source such as a lamp or heating plate. Measure the surface temperature with a thermometer over time. Polyethylene terephthalate films will register an earlier increase in temperature. Polyimide films will exhibit lower temperatures due to their molecular structure, which inhibits heat transfer. Record temperature changes at regular intervals. This test simulates what occurs in an electronic device.

• Electrical Insulation Experiment:

Measure the resistivity of each film using a multimeter. Set the device on a high resistance scale and press the probe into the film's surface. The reading indicates dielectric strength. Polyimide films will yield a higher resistance reading, teaching why these materials are preferred in circuits prone to electrical breakdown.

• Mechanical Strength Comparison:

Conduct a trial with both films to compare tensile strength. Clamp both films in position and gradually apply weights. Determine which sample extends less when subjected to tension. While polyethylene terephthalate films can be quite flexible, polyimide films will maintain their shape under stress. A pull test can reveal critical information about each material's integrity.

Chemistry

• Molecular Structure Investigation:

Construct models using paper or clay to demonstrate each repeating unit. The model for polyethylene terephthalate will depict long chains of ester groups connecting them, while the polyimide model illustrates aromatic rings and imide groups. Building these models can help anticipate how and why a given structure withstands heat more effectively.

• Heat Stability and Decomposition

Demonstrate how each film reacts when exposed to temperatures beyond their tolerance. Polyethylene terephthalate will degrade at approximately 250°C, whereas polyimide films will resist temperatures exceeding 400°C before degradation. This demonstration must be conducted in a controlled environment using appropriate protective equipment.

• Polymerization Simulation:

Illustrate the polymerization process by linking objects such as paper clips or small beads together in a chain. This demonstrates how individual monomers combine to form long chains, emphasizing why the polyimide chain structure is so durable. Using solid models provides tangible representation of these abstract concepts.

Technology and Applications

• Real-World Connections

Flexible displays and packages commonly employ polyethylene terephthalate films. It is likely that you are reading from a touchscreen or using a plastic bottle containing these films. Polyimide films are utilised in environments where high temperatures are prevalent, such as in flexible printed circuit boards and spacecraft insulation components.

• STEM Challenge:

Create a challenge to construct a “heat shield” using polymer film strips to protect a small sensor from a heat source. Document measurements to evaluate which film offers superior protection. This challenge combines design with scientific testing, illustrating practical aspects of engineering.

• Data Recording

Incorporate devices such as thermocouples or basic Arduino sensors to record temperature variations during experiments. This approach adds a technological element to the experiments. It is feasible to teach data recording principles, blending physics, chemistry, and computer coding within one laboratory activity.

Conclusion

Polyethylene terephthalate and polyimide films are critical materials employed in heat-sensitive electronics today. Their molecular structures make them suitable for numerous electronic applications. Two experiments can clearly demonstrate the differences between them in terms of thermal resistance, electrical insulation, and mechanical strength. These practical experiments effectively bridge theoretical knowledge with real-world applications. For further details on STEM experiments, please refer to Stanford Advanced Materials (SAM).

Frequently Asked Questions

F: What is the main difference between polyethylene terephthalate and polyimide films?

Q: Polyethylene terephthalate films are suitable for moderate heat, whereas polyimide films are suited for high heat.

F: Are the two films applicable in flexible electronics?

Q: Yes, polyethylene terephthalate is common in flexible displays, while polyimide is used in printed circuit boards.

F: Why do electronic devices require these films?

Q: They provide protection from heat for components, offer electrical insulation, and enhance overall device reliability.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

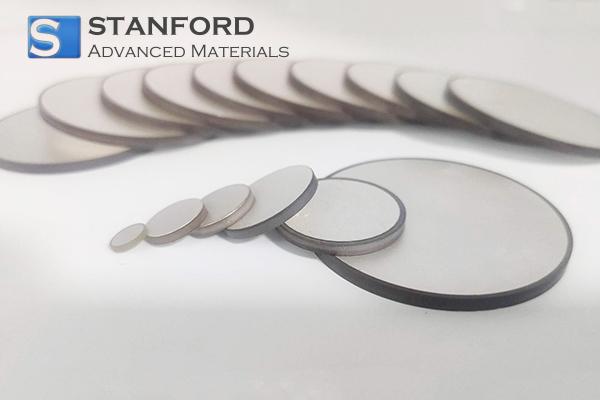

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Dr. Samuel R. Matthews

Dr. Samuel R. Matthews