From Laboratory to Life: Learning Quartz and Borosilicate Glass Properties

Introduction

Glass materials are at the focal point of our everyday lives and laboratory settings. They feature in equipment and machinery we use daily. They are central in research laboratories and industries for precision and safety. Quartz glass and borosilicate glass occupy pivotal positions in science, industry, and technology. They are chosen due to their unique properties.

What Is Quartz Glass?

Quartz glass consists mainly of silicon dioxide (SiO₂). It exists in two forms: natural quartz and synthetic quartz. Natural quartz is formed in the earth over thousands of years. Synthetic quartz is produced under controlled conditions for high purity.

Quartz glass is very pure and very transparent. It is transparent, which makes it perfect for optical applications. It is very thermally stable. Thermal stability brings minimal alteration to its structure. Quartz glass has low thermal expansion. It does not change its shape even when heated and cooled repeatedly. Quartz glass is very hard and chemical-resistant. These properties prove convenient in harsh environments and high-temperature processes.

Quartz glass is typically used where any contaminants would compromise precise measurements. Optic clarity is essential in most scientific devices and high-technology applications. Specialty optical components for spectroscopy and high-temperature furnaces are available to be utilised by laboratories using quartz glass.

What Is Borosilicate Glass?

Borosilicate glass is made by combining silicon dioxide, boron oxide (B₂O₃), and some minor oxides. The exact formula may vary from company to company. This type of glass became popular through products like Pyrex, which have been around for many decades.

The introduction of boron oxide gives this glass its unique properties. Borosilicate glass has greater thermal shock resistance. It withstands sudden changes in temperature without breaking. Its chemical resistance is moderate and accepts most laboratory chemicals. Its thermal expansion is lower than that of the usual soda-lime glass. This discourages breakage when the glass rapidly cools or heats up. Borosilicate glass is also tough mechanically, making it endure everyday uses like cooking and chemical storage.

This glass is commonly applied in products that need both strength and thermal resistance. It is found in laboratory beakers, flasks, and condensers. Its properties also make it frequently used in cookware in homes.

Differences between Quartz and Borosilicate Glass

The two glasses have varying properties. Below is an outline of their differences:

Thermal Properties:

• Quartz glass softens and melts at extremely high temperatures. Its low thermal expansion characteristics render it extremely useful for high-temperature applications.

• Borosilicate glass has a lower melting point than quartz. Its thermal shock resistance is a major advantage for laboratory and general purpose use.

Mechanical Properties:

• Quartz glass is very hard. It is also brittle. It will break on impact.

• Borosilicate glass is less breakable. It has good mechanical strength and can endure some shocks better.

Chemical Durability:

• Quartz glass is resistant to most chemicals like acids and bases.

• Borosilicate glass has moderate chemical resistance, which is sufficient for most laboratory applications but will be broken down by strong acids and bases over time.

Optical Properties:

• Quartz glass has good transparency and good ultraviolet (UV) transmittance.

• Borosilicate glass is also transparent but can have minor variations in UV transmission depending upon the additives in its composition.

Laboratory Applications

Quartz glass is used in laboratories because it is stable at high temperatures and pure. Scientists use quartz components in high-temperature furnaces. Its stable and clear state favours optical instruments. Some spectroscopy equipment uses quartz glass due to its precision.

Borosilicate glass is ubiquitous to most laboratory equipment. Beakers, flasks, and condensers are made of borosilicate glass. Its thermal shock resistance is an accident preventer when there is rapid temperature change. Chemical processing equipment also makes use of its resistance to wear and tear. The two glasses are used for different laboratory functions. Quartz glass is used for purposes that require very high purity and stability. Borosilicate glass is suitable for everyday laboratory applications and general chemical processing.

Industrial and Normal Uses

Quartz glass finds applications in modern use in everyday equipment and high-tech industries. It is found in fibre optics where accuracy and transparency are needed. Electronics and semiconductor manufacturing also rely on quartz glass. Quartz crystals are used in watchmaking for precise clockwork for watches.

Borosilicate glass is widely recognised in households and industries. Borosilicate glass cookware can tolerate heat. Laboratory products, which are common in schools, are made from this material. Lighting components frequently are made of borosilicate glass because of its resistance to thermal shock. Additionally, chemical storage flasks manufactured from borosilicate glass are reliable and durable.

Choosing between such types of glass depends on cost, hardness, and performance needs. Quartz glass has greater chemical purity and extreme heat resistance. Borosilicate glass achieves a balance between cost and performance for household and business utilisation.

Hands-On Experiments to Observe Properties

Simple experiments help understand these glasses better. The following experiments may be performed in a home or school laboratory.

Heat Resistance Demonstration:

Place some quartz and borosilicate glass in separate sources of heat. Observe how they handle changes in temperature. Quartz glass must withstand extreme heat and not lose its shape. Borosilicate glass is able to handle sudden change well.

Transparency and Refractive Index Observation

Both kinds of glass should be illuminated with a light source. The way light refracts through both materials should be observed. Quartz glass generally has clear and consistent refraction. Borosilicate glass is transparent but may show minute differences.

Add a drop of mild acid or base to each sample. Allow it to stand for a short time and rinse out the glass with water. Quartz glass is barely affected due to its high resistance. Borosilicate glass will probably exhibit minor reactions, attesting to its low resistance.

These tests illustrate how every type of glass acts under stress. They demonstrate why certain types are selected for particular use. A simple test demonstrates differences in heat stability, light transmission, and chemical resistance.

Conclusion

Quartz glass and borosilicate glass both have special properties which are appropriate for different applications. Quartz glass is superior in purity, temperature stability, and low thermal expansion. It is most appropriately used in high-temperature and high-precision settings in laboratories and industries. Borosilicate glass has better thermal shock resistance, moderate chemical stability, and good mechanical strength. It is extensively used in laboratory equipment, cookware, and industrial components. For more information and STEM experiments, please check Stanford Advanced Materials (SAM).

Frequently Asked Questions

F: Why is quartz glass appropriate for high temperatures?

Q: Its purity and thermal stability allow it to resist severe temperature changes with minimal expansion.

F: Why is borosilicate glass common in cookware?

Q: Its hardness and high thermal shock resistance enable it to be safe for use with cooking and pouring hot liquids.

F: How does quartz and borosilicate glass differ in chemical resistance?

Q: Quartz glass has higher chemical resistance while borosilicate glass offers moderate resistance.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

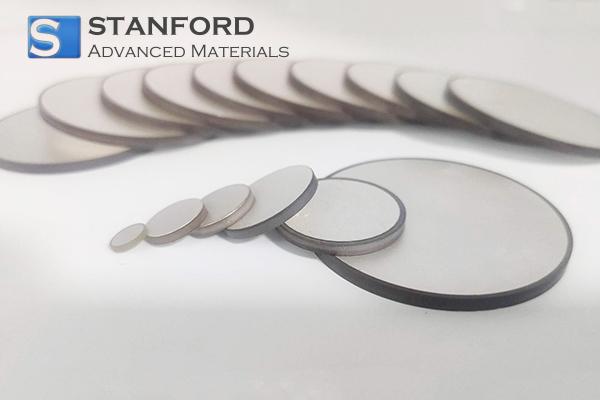

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Dr. Samuel R. Matthews

Dr. Samuel R. Matthews