Hands-On STEM: Testing Hardness and Abrasion of Ceramic Materials

Introduction

Ceramic materials are known for their strength and wear resistance. Ceramic materials are used for everyday items such as tiles, dinnerware, and engine components. Their reliability arises from their hardness and resistance to wear. Testing these properties is a practical part of science and engineering education. Using tried and tested techniques, one can measure the durability of ceramics in a laboratory setting.

Understanding Ceramic Materials

Ceramics are inorganic, non-metallic solids. They are usually produced by heating raw materials at high temperatures. These materials possess a crystalline structure. This structure imparts unique qualities to ceramics. For instance, many ceramics resist heat and wear. They often do not conduct electricity, making them useful as insulators.

Common ceramic materials include alumina, zirconia, and silicon carbide. Data from various studies reveal that alumina can have a hardness measured at around 15 on the Mohs scale. Zirconia typically exhibits excellent toughness and a lower wear rate when compared to other ceramics. In practical applications, engineers may select zirconia for components that must withstand stress and contact wear.

Engineers and technicians have long relied on ceramics. Examples include brake discs and cutting tools. In construction, ceramic tiles are common because they resist abrasion from foot traffic. Academic tests often use known materials as standards to calibrate the instruments employed in hardness and abrasion tests.

A classroom experiment might involve comparing the properties of different ceramics. For instance, one might measure the surface hardness of an alumina specimen against that of zirconia. This provides a practical session that links theory with practical measurements.

Hardness Testing

Hardness is a measure of resistance to localised plastic deformation. In practical terms, hardness tests on ceramics indicate how far a tool or object can scratch or press into the surface. One of the most common hardness tests used is the Vickers Hardness Test. In this method, a diamond pyramid indenter is pressed into the material at a controlled force. The size of the indentation is measured subsequently.

Another common method is the Knoop Hardness Test. This test utilises a diamond indenter that produces an elongated mark. The choice between the two methods depends on the sample size and the nature of the ceramic material. A practical example from our laboratory involved using the Vickers method on a zirconia sample. Under a force of 9.8 newtons, the indent was measured, and the hardness value was calculated. The measured hardness values typically ranged between 1200 and 1600 Vickers Hardness Numbers. Such numbers indicate a high resistance to deformation.

Hardness testing requires careful sample preparation. The surface must be smooth and clean. Any surface cracks or impurities can lead to incorrect measurements. In a classroom experience, a senior technician once stressed that the first step is always to polish the surface. This simple step significantly enhances the reliability of the results.

Abrasion and Wear Resistance Testing

Abrasion testing measures a material’s resistance to wear. When you test for abrasion, you subject the ceramic to friction and compare how quickly the surface is worn away. One standard method is the Taber Abrasion Test. In this test, a rotating abrasive wheel is pressed against the ceramic surface. The wear is measured by the weight loss of the sample after a set number of cycles.

Another method employs a reciprocating wear tester. The ceramic specimen is placed on a moving platform while a constant force is applied to an abrasive material. The method is straightforward and provides clear data. For example, tests on a silicon carbide specimen demonstrated a weight loss as low as 0.05 grams after 1 000 cycles. This indicates that the material withstands abrasion effectively.

Engineers have long used these tests for both research and quality control. In an industrial case, manufacturers of dental ceramics utilised abrasion testing to ensure that crowns and bridges can endure wear from chewing. Similarly, automotive parts made of ceramics underwent tests for abrasion resistance to minimise wear over time.

Surface treatments and additives can modify the wear characteristics of ceramics. Adding a small proportion of yttria in zirconia assists in stabilising the structure. In experiments, ceramics with yttria exhibit improved resistance to wear without sacrificing hardness. The combination of microstructural studies and abrasion tests yields valuable insights into how ceramics behave under stress.

Applications of Hard and Wear-Resistant Ceramics

Many everyday items rely on hard and wear-resistant ceramics. One common application is in the production of tool inserts for machining. These inserts often experience high temperatures and friction. The superior hardness and abrasion resistance enhance the longevity of the tools.

Another example is in parts used for transportation. Ceramic brake pads and engine components benefit from high wear resistance. In one instance, a study indicated that ceramic brake pads exhibited a wear rate nearly 30 per cent lower than traditional materials. This results in longer life and reduced maintenance.

A third application can be observed in electronics. Ceramics employed in electronic devices often need to insulate as well as resist abrasion, especially in portable devices where drops are common. Engineers ensure minimal wear by selecting ceramics with appropriate hardness values and robust microstructures.

Medical devices also utilise ceramic materials. In dental implants, ceramics are selected for their biocompatibility and strength. A common hospital case report described the successful use of zirconia-based implants that combined both high hardness and resistance to abrasion. The long life of these implants makes them favourable even in routine dental procedures.

The testing methods outlined assist in selecting the right ceramic for each application. Hardness testing provides a measure of the material’s strength on a microscopic level. Abrasion testing assures that the material will withstand repeated stress. Both tests are simple to perform in a school or laboratory setup. They contribute to better material selection and enhanced product performance.

Conclusion

In summary, the testing of hardness and abrasion of ceramic materials is a key part of hands-on science education. Simple methods like the Vickers Hardness Test and Taber Abrasion Test yield clear and useful data. Ceramic materials such as alumina, zirconia, and silicon carbide demonstrate qualities that suit sharp edges, high foot traffic conditions, and high-demand electronic environments.

Real-life measurements reinforce that ceramics perform well when their microstructure is appropriately controlled. Practical classroom tests help students understand why certain ceramics are chosen over others for specific applications. Many students gain confidence after performing these tests. Their learning is enriched by real data and hands-on work.

Ceramics are versatile and widely used. Whether one works in construction, electronics, or healthcare, hard and wear-resistant ceramics play a vital role. Testing these materials helps improve performance, reduce costs, and increase product life. With simple experimental setups and clear data, students and practitioners alike can better understand the properties of ceramics.

Frequently Asked Questions

F: What is hardness testing on ceramics used for?

Q: It measures a ceramic’s resistance to deformation and scratch marks through controlled indentation.

F: What does abrasion testing evaluate in ceramic materials?

Q: Abrasion testing assesses the material’s wear resistance by measuring weight loss after friction.

F: Can hardness and abrasion tests be performed in school laboratories?

Q: Yes, both tests employ straightforward methods and equipment suitable for educational settings.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

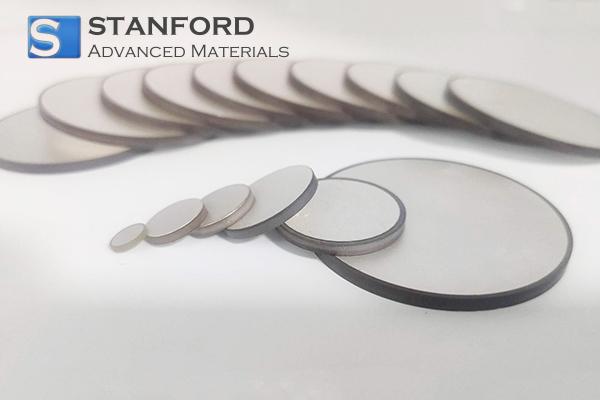

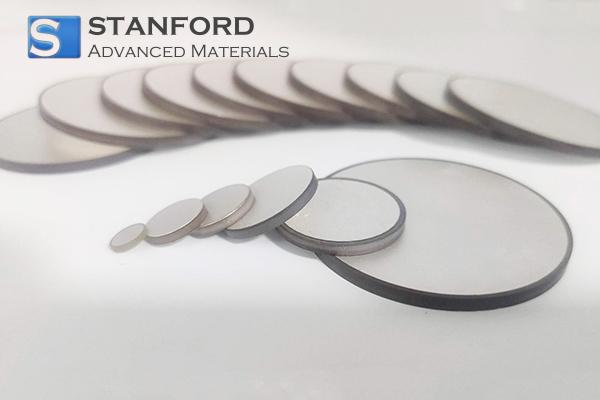

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Dr. Samuel R. Matthews

Dr. Samuel R. Matthews