Iridium and Its Aerospace Applications: The Extreme Environment Metal

Introduction

Iridium is one of the world's rare elements—resilient and nearly indestructible. Its silvery-white luster and high physical stability have interested scientists and engineers for many years. It appears in the periodic table with the symbol Ir and atomic number 77 and is categorised as one of the platinum group metals (PGMs), which include platinum, rhodium, palladium, osmium, and ruthenium.

Although it makes up only 0.001 parts per million of the Earth's crust, iridium's combination of characteristics—such as melting point, corrosion resistance, and hardness—applies in the most demanding environments where durability is needed, particularly in aerospace technology.

Properties of Iridium: A Metal beyond Comparison

The physical and chemical characteristics of iridium are nearly unrivalled. It has a melting point of 2,446 °C and a boiling point of about 4,500 °C, ranking among the most refractory metals. Its density (22.56 g/cm³) is second only to osmium, which gives it a record mass per unit volume and strength.

Chemically, iridium is extremely inert. It resists corrosion by acids, oxidation, and most corrosive materials even at elevated temperatures. Unlike most metals, it does not tarnish in the atmosphere or react easily with acids or water, which has earned it recognition as one of the most corrosion-resistant materials known.

Mechanically, iridium is hard and brittle in its native form, but alloying—especially with osmium or platinum—allows for easier machining while maintaining greater durability. These alloys exhibit outstanding wear resistance and retain mechanical properties at temperatures at which most metals would vaporise or deform.

For these reasons, iridium is frequently used when materials must function reliably under extreme or highly reactive conditions, as in aerospace applications under high-temperature circumstances and in space exploration.

Further reading: Iridium: Element Properties and Uses

Iridium Alloys: Enhancing Performance through Synergy

Pure iridium is highly stable, but its brittleness complicates machining and fabrication. This issue is resolved through alloying with other metals, expanding its potential applications.

• Iridium–Platinum Alloys:

These are commonly used in aerospace and industrial thermocouples, employed as electrodes and as temperature-sensing junctions for conditions exceeding 1,800 °C. The addition of iridium improves the oxidation resistance of the alloy and its service life under severe conditions.

• Iridium–Osmium Alloys:

Due to their resistance to wear and hardness, these alloys are utilised in precision instrument pivots, bearings, and electrical contacts subjected to continuous mechanical stress.

• Iridium–Rhenium Alloys (Ir-Re):

The most significant aerospace alloy, Ir-Re combines iridium's heat resistance with rhenium's ductility. This produces a metal resistant to temperatures above 2,000 °C while maintaining toughness and creep resistance. The alloy is particularly important in rocket motors, especially for thrust chamber liners and nozzles exposed to high temperatures and reactive exhaust gases.

These iridium alloys are typically produced by powder metallurgy or chemical vapour deposition since iridium has a high melting point and is difficult to cast using conventional methods.

Aerospace Applications of Iridium

Iridium in aerospace engineering is mostly discreet but essential. Its exceptional stability in extreme thermal, chemical, and mechanical conditions makes it ideal for applications where any failure is unacceptable.

1. Rocket Engines and Propulsion Systems

The most significant aerospace application of iridium is in rocket engine hardware. The Ir-Re alloy is used in the lining of the thrust chamber, which is directly exposed to combustion gases exceeding 2,000 °C. Iridium provides an oxidation and erosion barrier against high-velocity exhaust.

A well-known application is NASA's utilisation of Ir-Re alloys in bipropellant rocket engines for deep space missions. The Voyager, Cassini, and New Horizons spacecraft all employed iridium-lined combustion chambers to ensure reliable long-duration thrust in the vacuum of space. These engines must perform accurately year after year without maintenance—an assurance provided by iridium.

2. Satellite Power Systems and Communications

Iridium's application is not limited to propulsion. The element plays a significant role in the Iridium satellite constellation, a network of over 60 operational satellites facilitating global communications. Although the constellation's name derives from the element due to its 77 originally planned satellites (matching iridium's atomic number), iridium is also utilised in specific satellite components.

In contacts and connectors, iridium coatings resist oxidation while providing stable conductivity in the presence of radiation and thermal cycling in space. The qualities that make iridium suitable for engine chambers also ensure electrical integrity in space electronics.

3. Thermocouples and Sensors

In aerospace monitoring and testing systems, temperature measurement is critical. Iridium-platinum thermocouples measure extreme temperatures in rocket nozzles, turbines, and re-entry vehicles, remaining stable and precise up to 2,000 °C, unlike most sensor materials which would melt or deteriorate.

4. Spacecraft Re-Entry and Protective Coatings

Iridium is also sometimes employed as a protective coating on high-temperature components, particularly in re-entry vehicles and probes subjected to atmospheric friction. Thin, adherent iridium coatings with significantly enhanced oxidation and erosion resistance can be formed using chemical vapour deposition (CVD) processes.

An example includes iridium-coated rhenium satellite attitude control thrusters, which have demonstrated operational lifespans exceeding 10,000 ignition cycles—far surpassing the performance of standard nickel or platinum coatings.

Conclusion

Iridium remains at the forefront of material science and aerospace engineering. Its heat resistance, corrosion resistance, and resistance to mechanical abrasion makes it a key metal for space propulsion, sensors, and shield coatings. From the core of rocket engines to satellite circuitry, iridium shapes the future of aerospace silently and effectively. For more information, please refer to Stanford Advanced Materials (SAM).

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

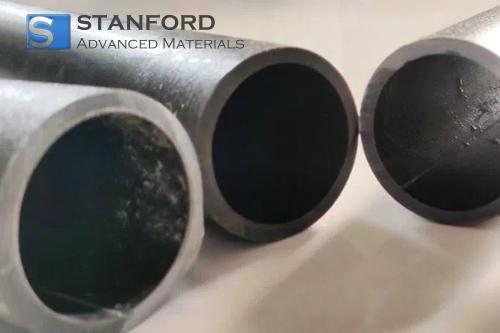

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento