Influence Of Nanomaterial In Soft Soil Stablization: Nanosilica & Nanoclay

Abstract

Engineers and planners frequently employ soil improvement methods by adding various stabilisers, which are generally used to enhance soil quality. Modern methods such as the addition of nanoparticles to weak natural soils to fill pores on the nano scale (between 1 nm and 100 nm) and to improve all geotechnical parameters are classed as nanotechnology. In this study, laboratory tests were conducted to quantify how stabilising soft soil with nano soil particles – Nanoton and Nanosilica – affects its geotechnical properties. The primary objective of this investigation was to assess how modest concentrations of Nanosilica and Nanoton (0.05%, 0.15%, 0.25% and 0.35%) improve the physical characteristics of the soil. The use of nanomaterial stabilisation resulted in measurable improvements in geotechnical parameters, including index values and technical properties, enhancing soil strength and the effective shear strength of the soft soil. Furthermore, the soil showed improved performance when treated with the optimal dosage of Nanoton. With 1% Nanosilica and 0.15% Nanoton, dry densities of 1.81 kN/m² were obtained. Following 28 days of curing, the unconfined compressive strength increased from 0.201 MPa to 0.821 MPa for samples treated with 1% Nanosilica and 0.15% Nanoton, as the pore spaces were filled by nanoparticles and the compressive strength of the soil improved. The stabilisation is advantageous for slopes associated with stability, transportation, geotechnical and civil engineering considerations.

Keywords

Nanosilica, Nanoton, unconfined compressive strength, Standard Proctor Test

1.Introduction

In most cases natural clayey soils cannot fulfil the load‐bearing requirements of modern geotechnical projects. Due to their high compressibility, considerable swelling and shrinkage potential, low permeability and reduced shear strength, soft soils pose significant engineering challenges. According to [2] soft soils display unpredictable behaviour and unfavourable technical properties. The process whereby materials are added to the soil or its natural properties are altered to improve technical parameters such as strength, durability and deformation resistance is termed soil stabilisation. Stabilisation techniques are generally classified into mechanical, chemical and physical methods. Generally, the strength and deformation characteristics of the subsoil can be modified by the addition of various treatment materials [7], [13], [12], [19] & [20]. These substances are grouped into composite hardeners, ionic soil stabilisers and inorganic binders. In chemical soil modification, inorganic binders (such as cement, lime, fly ash and mixtures thereof) are commonly used alongside other stabilising materials [3]. According to [18] cement‐treated soils exhibit a more brittle stress–strain response at lower initial mean effective stresses or with higher cement content, accompanied by an appreciable increase in both the elastic modulus and peak strength. As reported in [12], the incorporation of polypropylene fibres into cemented soils increases the fibre content which in turn raises the principal stress ratio at failure as well as the peak and residual shear strengths. In a series of experiments, [15] demonstrated that the addition of Nanosilica to clayey soils reduced the swelling index of the clay. Researchers with interests in technical applications—especially in civil engineering—have recently focused on nanomaterials and nanoparticles. Nanomaterials are a class of ultra‐fine materials with particle sizes between 1 and 100 nm and a high specific surface area. An increase in the overall surface area and their catalytic capability renders nanoparticles more reactive than their larger counterparts and facilitates the development of materials with new functionalities. Moreover, the high surface area of a nanoparticle improves contact between mixed components in nanocomposites, thereby increasing material strength. Consequently, they can be deployed to improve the properties of soils in various applications. A specific nanoparticle type, referred to as Nanosilica, consists of fine silicon dioxide particles. Nanosilica may offer several advantages when applied to clayey soils, some of which include improved soil quality. When clay is stabilised with additives such as fly ash, cement, silica fume and lime, the particles are microscopically small and have only marginal impacts on pore characteristics including compaction, shear strength, specific weight, plasticity index and permeability [4] [16]. These additives alone do not sufficiently enhance performance as the voids are only partially filled. Nanotechnology is therefore applied to fill soil pores on the nanoscale and densify the soil; this procedure consequently has a larger impact on permeability, specific weight, compaction, shear strength and the plasticity index. The size effect, quantum effect, surface effect and interfacial effect are the four principal structural properties of nanomaterials [6]. Nanomaterials offer various advantages for science, the environment, the economy and improved product quality. Among all nanomaterials, Nanoton has shown a notable performance with respect to soil index and technical properties. It has been demonstrated that the addition of extremely small amounts of Nanoton to the soil affects the liquid limit and the plasticity index [21]. Since their widespread adoption, the cost of nanoparticles has decreased significantly, thereby permitting their extensive use in the geotechnical industry.

In this study the effect of nanoparticles on clayey soil was investigated. Experiments were carried out on clay soils incorporated with Nanosilica and Nanoton. To determine the optimal ratio, the parent clay was initially amended with Nanosilica in increments of 0.7%, 1%, 1.2% and 1.5%. The samples were subsequently combined with Nanoton at dosages of 0.05%, 0.15%, 0.25% and 0.35%. A comparison was made between the properties of an untreated clay sample and a chemically stabilised clay sample. This paper presents an experimental investigation on the effectiveness of using nanomaterials (Nanoton and Nanosilica) to improve the strength properties and Atterberg limits of clayey soils. The experimental results quantify that the addition of a small quantity of nanomaterial significantly improves the geotechnical properties of soft soil.

2)Materials and Methods

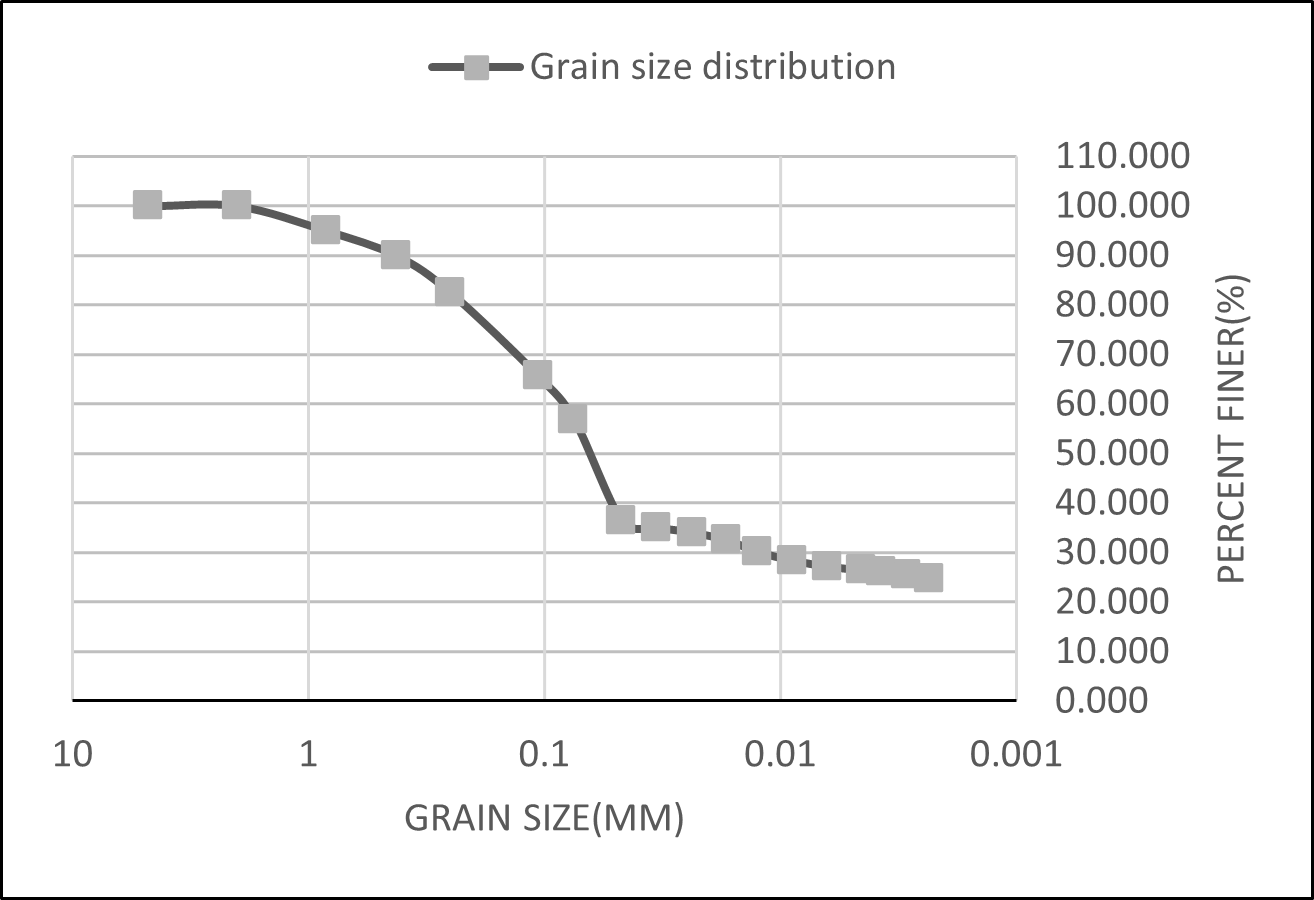

A sample of native soil was collected from Beel Dakatia. It is situated within the administrative boundaries of the Khulna District in the areas of Dumuria and Phultala, where 50% of the region is regularly inundated with water from 0.5 m to 2 m. The location is between longitudes 89°20′E and 89°35′E and latitudes 22°45′N and 23°00′N. The collected soil was clumpy, untreated and sampled in 25 kg bags. Subsequently, the soil was left to air-dry. Initially, the soil was moist; after air-drying, the clumps were manually broken down. The dried soil clumps were pulverised and then sieved in accordance with ASTM C136. The grain size distribution is presented in Fig. 1. As the quantity of the air-dried soil was insufficient for the experiments, it was oven-dried for 24 hours at 105 °C. The additives for this study were Nanosilica and Nanoton. Nanoton (600 g) was procured in Kolkata, India, and 1 kg of Nanosilica was obtained from Khulna Scientific Store, Khulna. The requisite amount for the tests was oven-dried for 24 hours at ambient temperature. Two types of specimens were prepared. Initially, 0.7%, 1%, 1.2% and 1.5% Nanosilica were mixed with the parent clay to determine the optimum Nanosilica content. Thereafter, Nanoton was added in respective proportions of 0.05%, 0.15%, 0.25% and 0.35% along with the optimised Nanosilica dosage to prepare the test specimens. For each test, four specimens were prepared using Nanosilica and Nanoton. The chemical composition of the utilised Nanosilica is detailed in Table 1.

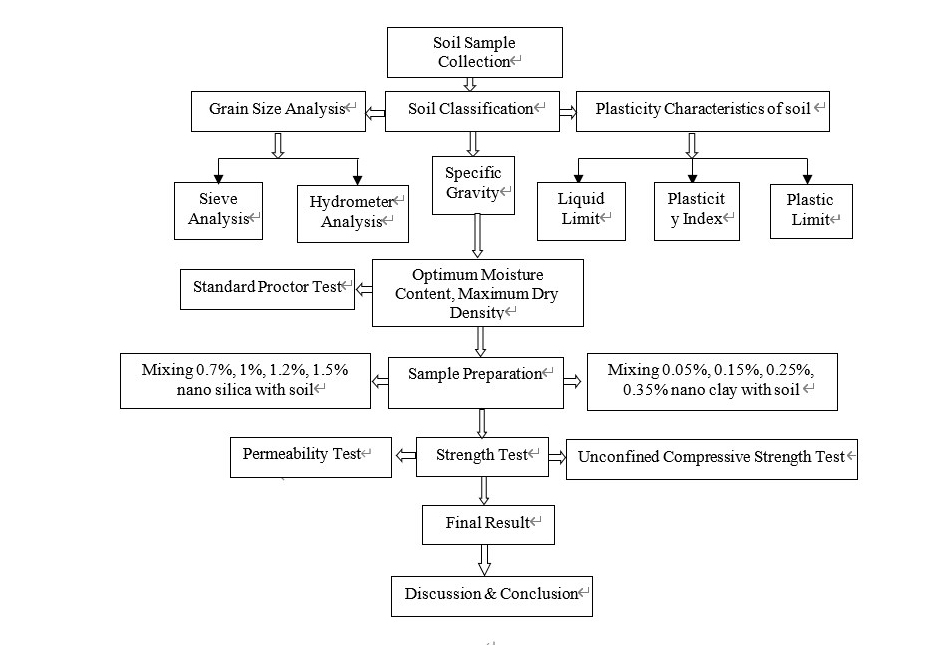

In this investigation, the parent clay sample was collected from the specified area and the specimens for testing were prepared in the laboratory. All tests were performed in the laboratory. The following flow chart illustrates the methodology employed in this study:

Table 1: Chemical Composition of the Utilised Nanosilica

|

Constituents |

Percentage of Component |

|

Silicon Dioxide(sio2) |

91.5% |

|

Magnesium Oxide (mgo) |

0.085% |

|

Calcium Oxide(cao) |

0.065% |

|

Sulphur Trioxide(so3) |

0.26% |

|

Aluminium Oxide (al2o3) |

0.085 % |

|

Sodium Oxide (na2o) |

0.97% |

|

Potassium Oxide (k2o) |

0.013% |

|

Titanium Dioxide (tio2) |

0.04% |

|

Iron Oxide (fe2o3) |

0.021% |

|

Calcium Oxide (cao) |

0.4% |

|

Manganese Dioxide (mno) |

0.003% |

Fig. 1: Grain size distribution of the test soil.

3Results and Discussion

3.1 Effect of Nano-Silica on the Stabilisation of Soft Soils

3.1.1Effect of Nano-Silica on the Atterberg Limits of the Soil

Fig. 2 illustrates the relationship between the liquid limit of the stabilised soil and the Nano-Silica content. Compared with the parent sample, the treated clay exhibited a lower liquid limit. The liquid limit increased with increasing Nanosilica content. The parent sample recorded a liquid limit of 43.25. The liquid limit for clay treated with 0.7% Nanosilica was 44.33. For a dosage of 1% Nanosilica the liquid limit was 44.64, while at 1.2% Nanosilica the value was 45.43. The maximum liquid limit was observed for the 1.5% Nanosilica-treated sample, reaching 45.86. In tests of the plastic limit, the value increased with the addition of Nanosilica. The parent sample had a plastic limit of 23.54, whereas with 0.7% Nanosilica the plastic limit increased to 25.98. The plasticity index varied with the different dosages. The parent sample recorded an index of 19.71 and the lowest plasticity index, 18.09, was observed for the optimally treated sample with 1% Nanosilica. The variation of the plasticity index is presented in Fig. 2d. According to Foad Changizi (2017), these results are consistent with the experimental findings. When estimating the potential settlement or consolidation of a soil under load, the Atterberg limits are employed as a field reference. If the field moisture content is near the liquid limit, significant settlement is anticipated; conversely, if it is near or below the plastic limit, the settlement will be reduced. Consequently, the application of 1% Nanosilica for soil stabilisation slows the rate of settlement. As a chemical additive, 1% Nanosilica thus optimises the properties of clay samples.

3.1.2Effect of Nano-Silica on the Compaction Properties of the Soil

A Standard Proctor Test was conducted. In this test the optimum moisture content decreased while the maximum dry density increased for the stabilised soil. The untreated clay showed an optimum moisture content of 18.6%. With increasing Nano-Silica content the optimum moisture content reduced, reaching 15.7% at 1.5% Nanosilica. The maximum dry density values were 1.75 kN/m², 1.766 kN/m², 1.78 kN/m², 1.77 kN/m² and 1.76 kN/m² respectively for untreated clay, 0.7%, 1%, 1.2% and 1.5% Nanosilica-treated soils. These findings compare well with those reported in [5] [1].

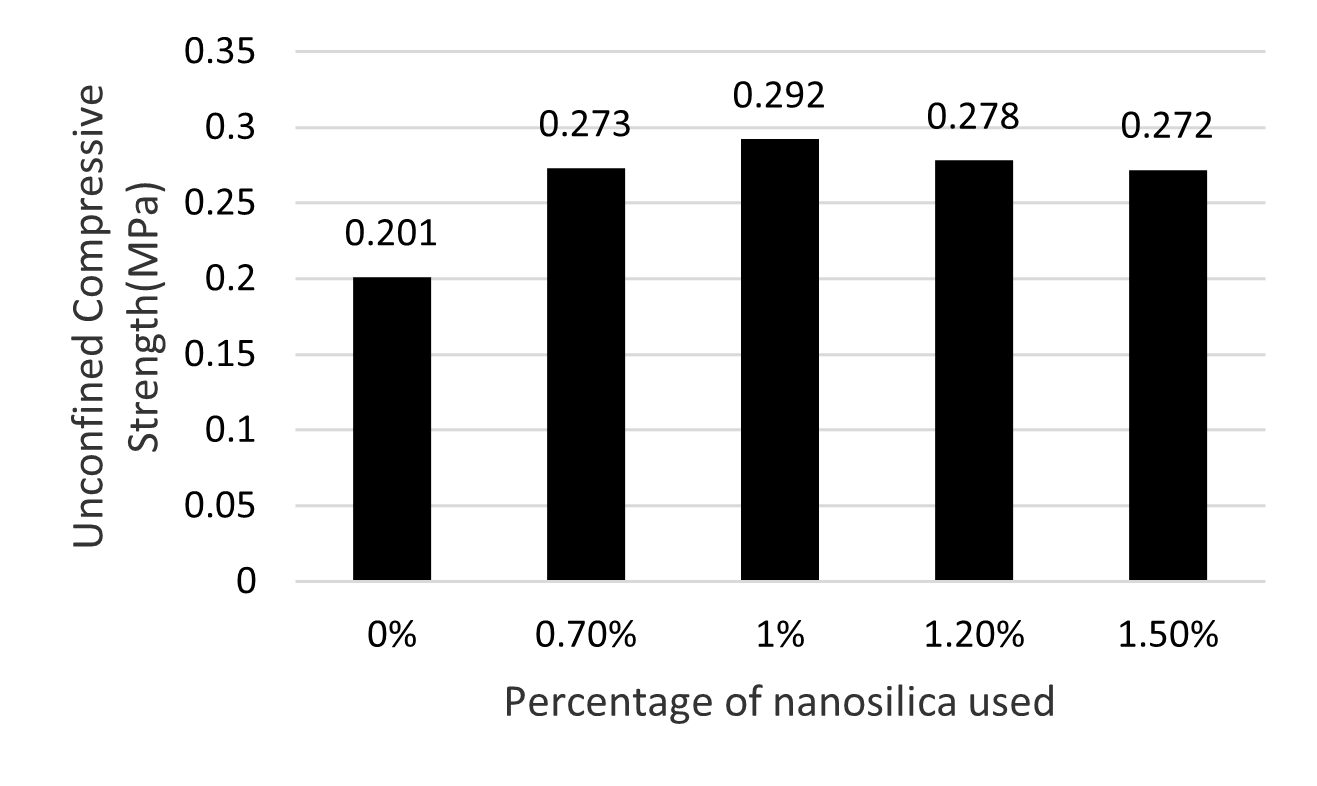

3.1.3Effect of Nano-Silica on the Unconfined Compressive Strength Test

The unconfined compression test (UCT) was performed to assess the mechanical properties of the soil. This test measured the undrained strength and stress–strain characteristics. The ratio of the 1-day strength for the Nanosilica-treated samples is presented in Fig. 4. Of all the percentages tested (0.7%, 1%, 1.2%, 1.5% of the soil’s dry weight), 1% Nanosilica produced the lowest plasticity index (a decrease from 21% to 19.5%) and achieved a significant maximum dry density (from 1.75 to 1.78 kN/m²). Therefore, 1% Nanosilica was selected as the optimal dosage.

Fig. 4: Unconfined Compressive Strength Test of the Soil Treated with Nanosilica

3.2 Effect of Nanoclay on Clayey Soil + 1% Nanosilica

3.2.1Effect of Nanoton on the Atterberg Limits of Soil + 1% Nanosilica

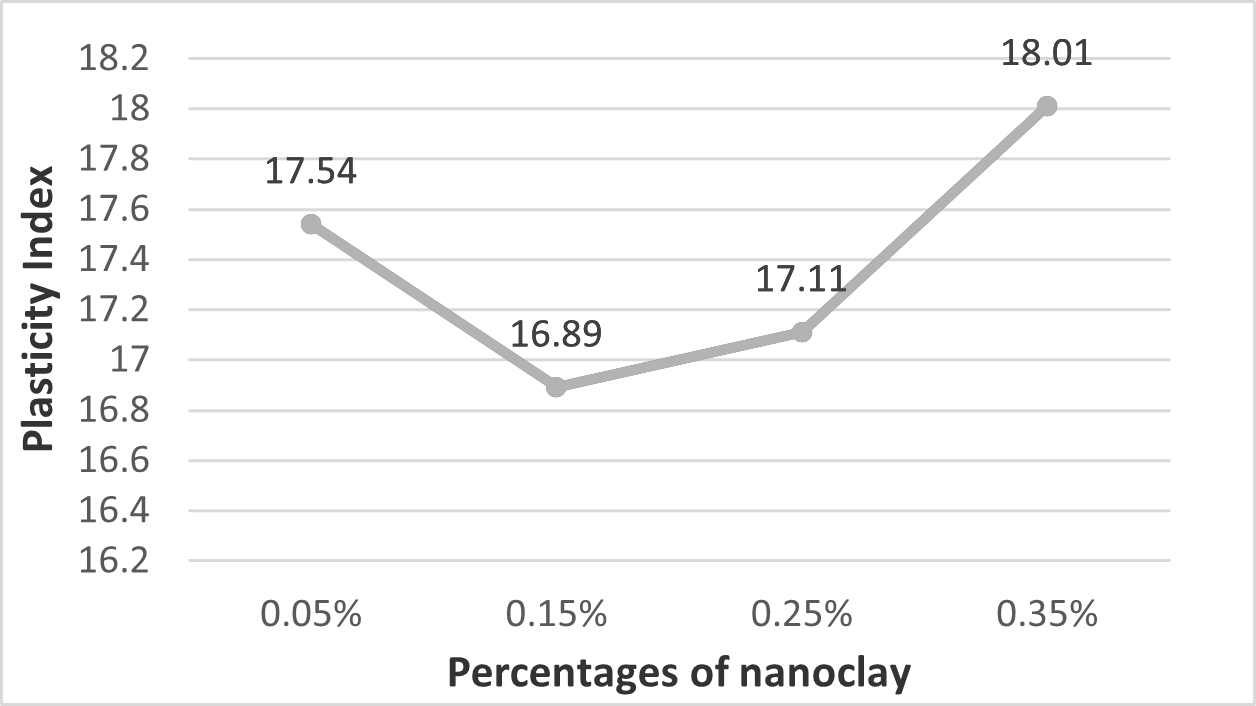

In our tests the liquid limit of the treated clay sample was lower than that of the parent sample. The liquid limit increased with the addition of both Nanosilica and Nanoton. The parent clay exhibited a liquid limit of 43.25. For clay treated with 1% Nanosilica + 0.05% Nanoton the liquid limit was 41.57. A dosage of 1% Nanosilica + 0.15% Nanoclay yielded a liquid limit of 41.89. With 1% Nanosilica + 0.25% Nanoton the value was 45.43, while the highest liquid limit of 45.86 was observed for the 1% Nanosilica + 0.35% Nanoton sample. In these tests the plastic limit of the stabilised soil increased; the parent sample recorded a plastic limit of 23.54, and with the addition of 1% Nanosilica + 0.05% Nanoton the plastic limit increased to 24.25. The plastic limit continued to rise with increasing Nanoton content. The plasticity index of the parent sample was 19.71, and the lowest plasticity index, 16.89, was obtained for the optimally treated soil (1% Nanosilica + 0.15% Nanoton) [8]. The variation of the plasticity index is depicted in Fig. 5.

3.2.2Effect of Nanoton on the Compaction Properties of Soil + 1% Nanosilica

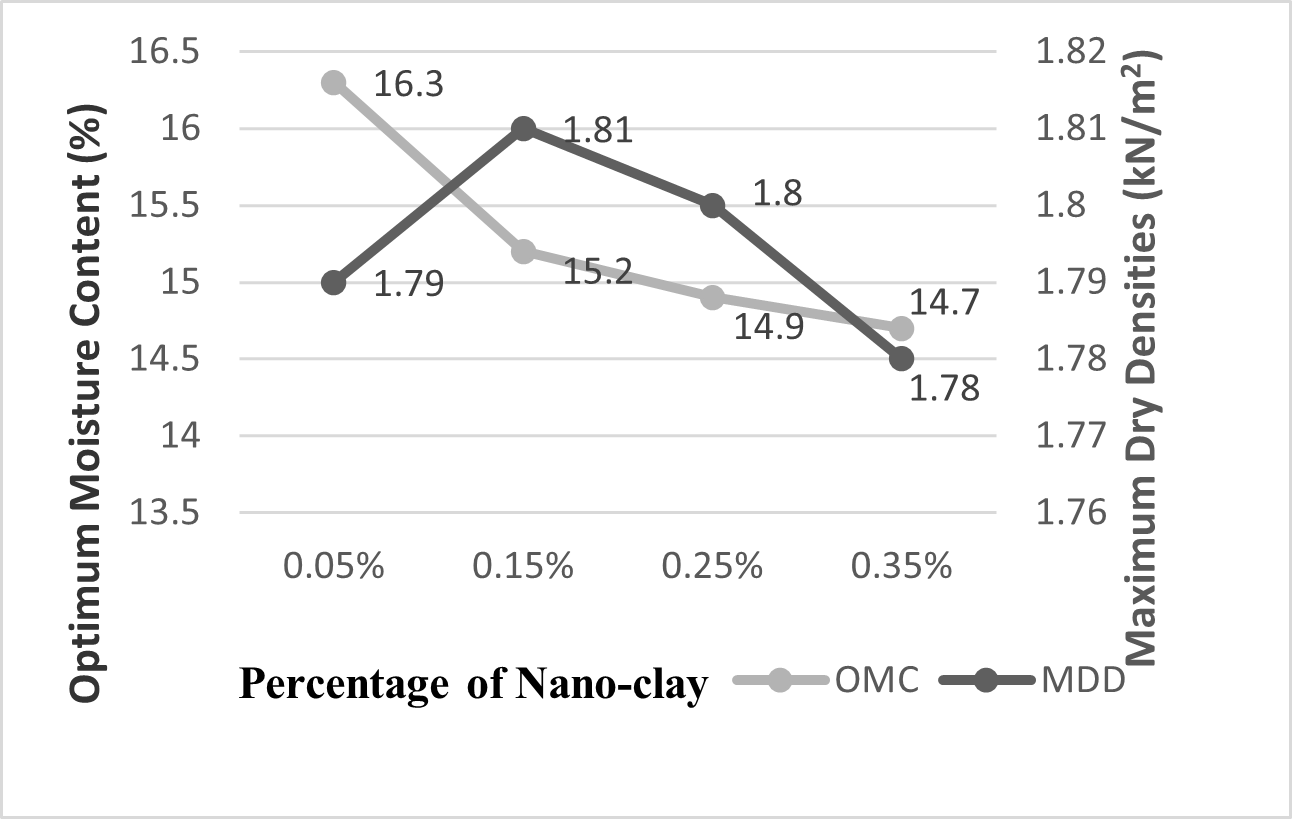

For the parent sample and for clay treated with 1% Nanosilica combined with 0.05%, 0.15%, 0.25% and 0.35% Nanoton, the optimum moisture contents were 16.3%, 15.2%, 14.9% and 14.7% respectively. Fig. 6 presents the compaction characteristics; these results conform with those reported in [11].

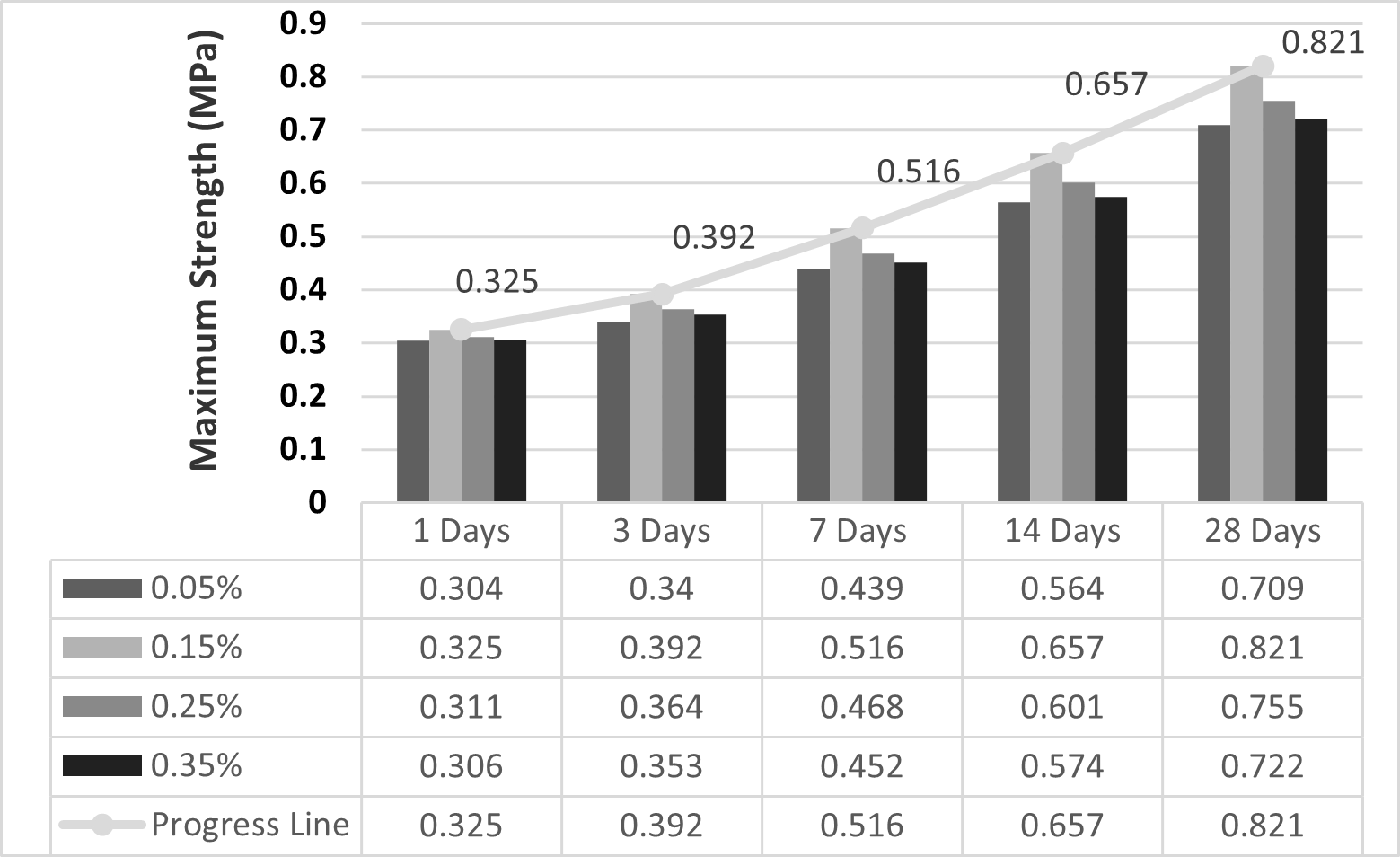

3.2.3Effect of Nanoton on the Unconfined Compressive Strength Test of Soil + 1% Nanosilica

To determine an ideal combination of Nanosilica and Nanoton, the optimal percentage of Nanosilica was combined with varying percentages of Nanoton. The UCT was conducted after 1, 3, 7, 14 and 28 days. A marked improvement was observed in the 14-day tests, attributable to the pozzolanic reaction. Once the optimal Nanosilica dosage was established, Nanoton was added in proportions of 0.7%, 1%, 1.2% and 1.5% to the optimal Nanosilica mixture. The maximum strength improvement was measured at 0.15% Nanoton, representing a 67% increase in strength. These results quantitatively confirm the findings reported in [11]. Consequently, the appropriate dosages of Nanosilica and Nanoclay for stabilising clayey soils were determined. The results are shown in Fig. 7.

Fig. 5: Plasticity Index (Clayey Soil + 1% Nanosilica + Nanoton)

Fig. 6: Compaction Characteristics of the Soil Treated with Nanoton

After 24 hours, the maximum strength improvement was 62% for the combination (1% Nanosilica + 0.15% Nanoclay). Among all percentages based on the soil’s dry weight, the 0.15% dosage produced the highest specific weight, the lowest plasticity index and the most significant maximum dry density. Therefore, a dosage of 0.15% Nanoclay was deemed optimal.

3.3 Effect of 1% Nanosilica + 0.15% Nanoton on the Permeability Test of Soft Soil

The soft clay was blended with the optimum moisture content, maximum dry density and the optimal dosages of Nanosilica and Nanoton in order to prepare specimens for evaluating permeability properties. The specimens were stored in sealed packaging to prevent moisture evaporation. The prepared specimens fulfilled the permeability criteria established in ASTM D2434 and were evaluated accordingly. In detail, the soft clay combined with 1% Nanosilica and Nanoton produced permeability parameters that were entirely different from those obtained in previous investigations [14]. The addition of the optimal dosage of Nanoton resulted in the filling of voids with nanomaterials at the nanoscale, rendering the soil essentially impermeable.

Table 2: Permeability Characteristics

|

Soil Type |

Untreated Soil |

Soil + 1% NS + 0.15% NC |

|

Coefficient of Permeability (cm/s) |

4.6*10-4 |

7.61*10-7 |

Fig. 7: Variation in Strength Improvement for Different Test Days (Clay + 1% Nanosilica + Nanoclay)

4.Conclusions

The following conclusions were drawn from the experimental study on the improvement of soft clay with Nanosilica and Nanoton, its index and technical properties:

- Low compressible clay (CL) is characterised by its Atterberg limits. The optimum moisture content (OMC) and maximum dry density (MDD) are 18.18% and 1.62 g/cc respectively.

- The unconfined compressive strength (UCS) of the clay was determined to be 0.201 MPa, and the coefficient of permeability was measured at 4.6×10-4 cm/s. The final consolidation settlement was approximately 4.4 mm, with a consolidation coefficient of 0.043 cm²/min, indicating highly compressible clay behaviour.

- The optimum moisture content, maximum dry density and percentage of Nanosilica (i.e. 0.7%, 1%, 1.2% and 1.5% of the soil’s dry weight) were evaluated with the soft clay.

- At 1% Nanosilica the maximum dry density increased to 1.78 kN/m² and the grain size distribution was affected.

- Among all the dosages, 1% Nanosilica produced the most quantifiable improvements.

- The sample treated with 1% Nanosilica exhibited the lowest plasticity index (reduced from 21% to 19.5%) and the highest maximum dry density (from 1.75 to 1.78 kN/m²) among the tested percentages. Therefore, a 1% dosage was selected as the optimal amount of Nanosilica to be added.

- The addition of Nanoclay influenced the grain size distribution and altered the liquid and plastic limits. The greatest reduction in the plasticity index was observed for soil treated with 0.15% Nanoclay.

- The maximum dry density increased to a maximum of 1.81 kN/m² when 0.15% Nanoclay was applied, affecting the grain size distribution.

- The highest specific weight, the lowest plasticity index and a significant maximum dry density were observed for soil treated with 0.15% Nanoclay based on the soil’s dry weight. For determining the optimal quantity of Nanoclay to be added, each trial used a 0.15% dosage.

- The treated soil exhibited essentially zero permeability as all the pores were filled with nanomaterials; hence, the optimal Nanoclay dosage rendered the soil impermeable.

References

[1] A. Mohamadzadeh Sani, M. A. (2010). Effect of Nanoclay Addition on the Geotechnical Properties of Silty Sands. Proc. of 4th International Conference on Geotechnical Engineering and Soil Mechanics, Tehran, 02/11/2010.

[2] A.M., A. W.-A. (2005). Application of the Electrokinetic Method as an Effective Approach for Soil Improvement. International Conference on Problem Soils GEOPROB 2005, Famagusta, N. Cyprus, 885-894.

[3] Cai, Y., & Shi, B. (2006). Effect of Polypropylene Fibres and Lime Addition on the Technical Properties of Clayey Soils. Eng. Geol. 2006, 230-240.

[4] Feynman, R. (1960). There is Plenty of Room at the Bottom. Eng. Sci. (California Institute of Technology), 22-36.

[5] Foad Changizi, A. H. (2017). Improvement of the Geotechnical Properties of Soft Clay Using Nano-Silica Particles. Proceedings of the Institution of Civil Engineers.

[6] Gao, L., & Ren, Z. (2015). Experimental Investigation of Clay Modified with Nano Magnesium Oxide. Soil Mech. Found. Eng. 2015, 218-224.

[7] Hejazi, S., Sheikhzadeh, M., Abtahi, S., & Zadhoush. (2013-14). Shear Modelling of Fibre Reinforced Soil Composites Based on Fibre Pull-Out Tests. Fiber Polym. 2013, 14, 277-284.

[8] Jamal M. A. Alsharef, 1. M. (2016). Potential for the Use of Nanocarbon Materials in the Stabilisation of Weak Soils.

[9] Jha, K. (2012). An Energy-Based Nano-Mechanical Properties Evaluation Method for Cementitious Materials. Florida International University, Miami, FL, USA, 2012.

[10] M, H. A. (2013). Effect of Fibre Reinforcement on the Triaxial Shear Behaviour of Cement-Treated Sand. Geotextiles and Geomembranes, 1-9.

[11] Meeravali Karumanchi, G. A. (2020). Enhancement of Consistency Limits, Specific Weight and Permeability Characteristics of Soft Soils Using Nanomaterials: Nanoclay. www.elsevier.com.

[12] Mirzababaei, M., Miraftab, M., Mohamed, M., & McMahon. (2013). Effects of Carpet Waste Fibre Addition on the Swell Characteristics of Compacted Clays. Geotech. Geol. Eng. 2013, 173-182.

[13] Mirzababaei, M., Yasrobi, S., & Al-Rawas. (2009). Effect of Polymers on the Swelling Potential of Expansive Soils. Proc. Inst. Civil Eng. Ground Improv. 2009, 111-119.

[14] Norazlan Khalid, M. F. (2015). The Influence of Nano Soil Particles on the Stabilisation of Soft Soils.

[15] QP, P. H. (2014). Impact of Silicon Dioxide Nanoparticles on the Swelling and Aqueous Stability of Nanoparticle Dispersions. Journal of Nanoparticle Research, 2137.

[16] R. Booker, E. B. (2005). Nanotechnology for Dummies. Wiley Publishing, 2005, 384.

[17] R. Zhu, S. L. (2010). A High-Resolution TEM Investigation of Nanoparticles in Soils. Environ. Soil Sci. Interfaces Earth Critical Zone, 282-284.

[18] Schnaid F, P. P. (2001). Characterisation of Cemented Sand in Triaxial Compression. Journal of Geotechnical and Geoenvironmental Engineering, 857-868.

[19] Soltani, A., Deng, A., Taheri, A., & Mirzababaei. (2017). A Sulphonated Oil for the Stabilisation of Expansive Soils. Int. J. Pavement Eng. 2017, 1285-1298.

[20] Soltani, A., Deng, A., Taheri, A., & Sridharan. (2019). Swell-Shrink-Consolidation Behaviour of Rubber-Reinforced Expansive Soils. Geotech. Test. J. 2019, 761-788.

[21] Z.H. Majeed, M. T. (2012). Effect of Nanomaterial Treatment on the Geotechnical Properties of a Penang Soft Soil. Asian Sci. Res. 2 (11) (2012), 587-592.

This is a submission for the SAM Scholarship 2024, submitted by Tausif Islam Chowdhury.

*Reporting Author

Tausif Islam Chowdhury* 1, Jhumana Akter 2, Musharrof Hossain Sunny3 & Fahim Shahariar Aditto4

1 University Student, Department of Civil Engineering and Management, Khulna University of Engineering & Technology, Bangladesh

2 Assistant Professor, Department of Civil Engineering and Management, Khulna University of Engineering & Technology, Bangladesh

3PhD Candidate, Department of Civil Engineering and Management, Khulna University of Engineering & Technology, Bangladesh

4PhD Candidate, Department of Civil Engineering and Management, Khulna University of Engineering & Technology, Bangladesh

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento