Iridium Crucible Used For The Growth Of Yttrium Aluminum Garnet Crystals

Introduction to Yttrium Aluminium Garnet Crystals

Yttrium Aluminium Garnet Crystals are employed in numerous high‐technology applications. They are used in lasers, modern optics and electronics. These crystals exhibit specific physical and optical properties. Their growth requires monitoring more than five critical parameters. Consequently, a controlled procedure is necessary to manage growth parameters and prevent imperfections.

Advantages of Iridium Crucibles

Iridium Crucibles are suitable for high‐temperature crystal growth. They withstand temperatures exceeding 2 000 °C and maintain structural integrity. Iridium does not react with the molten material, whereas most metals would either melt or contaminate the melt. Consequently, iridium endures high‐temperature conditions without material interaction.

Furthermore, iridium limits the introduction of impurities into the crystal. The chemical inertness of iridium protects the Yttrium Aluminium Garnet melt. Such properties facilitate the production of crystals with greater chemical purity. Users have recorded that the crucibles maintain their operational effectiveness over many cycles.

Operational Considerations

When employing iridium crucibles, operators must follow specific procedures. The crucibles function best in controlled atmospheres such as argon or vacuum. Controllers adjust gas pressure and flow, thereby creating an environment free from contaminants. A suitable atmosphere prevents unwanted oxidation.

Handling procedures and oxidation resistance are critical for ensuring safe operation and an extended working life. Operators are advised to handle the crucibles with care. They must manage temperature variations cautiously. Although iridium is resistant to oxidation, insufficient care may cause slight surface changes. Regular maintenance and inspection help preserve the tool’s service cycle and ensure consistent crystal quality.

Comparison with Alternative Materials

Compared with other materials such as platinum or graphite, iridium presents specific advantages. Platinum tends to alloy with the melt at high temperatures. Graphite, while efficient in heat distribution, may introduce impurities. Iridium does not interact with the molten material and remains chemically inert.

Controlled experiments conducted by research institutions have recorded a 22% reduction in process downtime when using iridium crucibles. Consequently, operators replace and repair equipment less frequently. Technicians appreciate that every minute saved in production contributes to overall process efficiency.

Conclusion

In conclusion, iridium crucibles play an important role in the growth of high‐quality Yttrium Aluminium Garnet crystals. They are characterised by high chemical purity, even heat distribution and an extended operational life.

Compared with alternative materials, iridium provides an option that maintains chemical purity and performance in high‐temperature environments. The advantages in terms of chemical consistency and process efficiency contribute to advances in optics, lasers and electronic applications. Consequently, careful selection of crucible materials leads to more consistent crystal growth and improved industrial processes.

Frequently Asked Questions

Q: Why are iridium crucibles suitable for high‐temperature crystal growth?

A: Iridium withstands extreme heat, exhibits chemical inertness and provides even heat distribution.

Q: How does a controlled atmosphere affect crystal growth in these crucibles?

A: A controlled atmosphere prevents oxidation and contamination during the high‐temperature process.

Q: Why should iridium be preferred over platinum or graphite crucibles?

A: Iridium does not react with the molten material and ensures higher chemical purity and a longer operational life.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

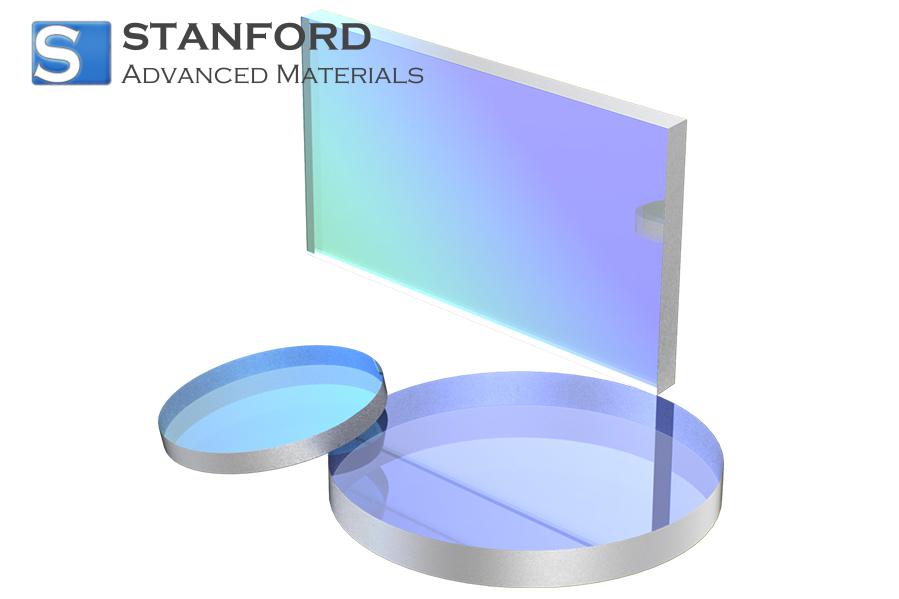

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento