Iridium Vs. Platinum: Choosing The Right Metal For Aerospace Components

Description

Components used in aerospace operate in severe environments. They encounter extreme temperatures, high loads and corrosive chemicals. Iridium and Platinum are metals with established performance. This article compares their behaviour and applications. The objective is to support the selection of a metal that meets design criteria and budget constraints.

Properties of Iridium

Iridium is a dense element. It has a melting point of approximately 2 446 °C. Its high melting point renders it suitable for components exposed to elevated temperatures. The density of Iridium, approximately 22.56 g/cm³, contributes to its mechanical strength. Consequently, turbine igniter plugs frequently incorporate Iridium tips, which can extend component lifespan and performance. However, Iridium requires careful handling during production, as it is brittle and sometimes necessitates specialised machining processes.

Properties of Platinum

Platinum is employed in industrial applications. Its melting point is around 1 768 °C and its density is approximately 21.45 g/cm³. The lower density can be beneficial in applications where weight is a critical factor. Platinum demonstrates corrosion resistance and chemical stability. In aerospace, Platinum is utilised in catalysts and sensor elements. Its improved formability may result in production cost savings and reduced waste.

Comparison of Costs

Cost is an important consideration when selecting between these metals. Iridium is rarer than Platinum, thereby leading to higher costs. An expensive material may be justified in high-demand situations if it provides long-term advantages. Conversely, Platinum may be preferred if budget constraints exist and the design permits a compromise in extreme thermal resistance.

Comparison of Mechanical Properties

The metals exhibit differences in mechanical properties. Iridium is employed in applications where even minor deviations can result in operational failures. Its high thermal stability and corrosion resistance make it suitable for high-temperature engine components. Platinum is softer but offers a balance of strength and ductility. Consequently, its ductility assists in absorbing vibrations and impacts encountered in aerospace configurations. Platinum is applied to reduce dynamic stresses in engines and machinery.

How to Decide

The selection between these metals depends on several factors. In certain designs, stiffness and thermal resistance are required, thereby favouring the use of Iridium. In other cases, improved formability and lower weight support the choice of Platinum. Designers must consider the operating environment to which each component will be exposed.

When selecting a metal for aerospace components, it is advisable to evaluate the operating environment, manufacturing processes and overall cost. Consequently, a thorough appraisal of these factors is necessary in a rigorous design process.

Conclusion

In summary, both Iridium and Platinum exhibit properties that render them suitable for aerospace components. Iridium possesses high thermal resistance and durability. Platinum provides improved formability and a lower weight.

Frequently Asked Questions

Q: What is the primary advantage of Iridium in aerospace?

Q: Iridium withstands high temperatures and oxidation, making it suitable for critical engine components.

Q: Why should Platinum be selected for certain aerospace applications?

Q: Platinum is easier to form, has a lower weight and maintains stability under varied conditions.

Q: How do engineers choose between Iridium and Platinum?

Q: Engineers consider temperature, weight, mechanical load and overall cost.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

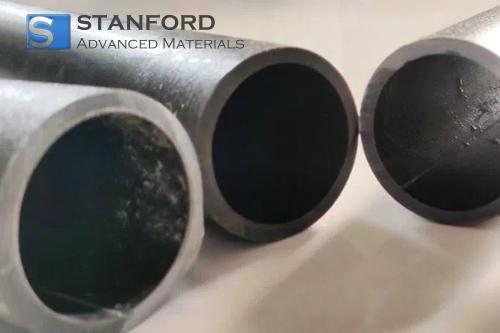

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento