List Of Sputtering Targets For Solar Energy

Description

Solar energy systems depend on thin films to capture light and convert it into electricity. Sputtering targets are used to deposit these films. The targets are usually composed of high-purity metal oxides or composite materials. They must exhibit the required electrical and optical properties. In addition, they are required to remain stable during the sputtering process. Manufacturers frequently select materials that have been validated over time.

List of Sputtering Targets for Solar Energy

One of the best-known targets is Indium-Tin Oxide. This material is used because it offers high transparency in the visible spectrum. It also provides reliable electrical conductivity. When used in solar cells, it produces a coating that does not interfere with light transmission. These targets typically achieve a purity level of over 99.99%. They are used to deposit films with thicknesses ranging from 100 to 200 nanometres, thereby contributing to an improvement in solar cell efficiency.

Another useful material is aluminium-doped Zinc Oxide. This oxide is preferred in solar energy applications because it is cost-effective and available in large quantities. Its optical transparency is comparable to that of Indium-Tin Oxide, and its electrical conductivity meets operational requirements. During sputtering, the film properties can be adjusted by varying the aluminium doping level. In many cases, manufacturers have determined that an aluminium concentration of between 1 and 3 per cent yields improved performance. This target is common in high-volume production and has demonstrated stability during continuous operation.

Zinc Oxide is also a common target material. It is valued for its high transparency and ease of processing. Zinc Oxide serves as both a conductive layer and a protective coating. In certain solar cell designs, a sputtered Zinc Oxide layer assists in regulating the light incident on the active layers. The material is produced with a purity level that ensures consistent film quality, typically above 99.9%. Practical examples have produced films with thicknesses between 150 and 250 nanometres. This control over film properties is essential for the production process.

A fourth material is Copper-Indium-Gallium Diselenide. This compound is used for thin-film solar cells because it exhibits effective light absorption and high conversion efficiency. In a sputtering target made of Copper-Indium-Gallium Diselenide, the components are carefully balanced. The resulting film has a uniform thickness optimised for light capture. In practice, reducing defects in the film remains an ongoing challenge. Over time, processing methods have been refined to improve film quality, thereby resulting in measurable improvements in solar cell efficiency.

In some sputtering processes, materials such as amorphous Silicon are used. Amorphous Silicon does not possess the ordered structure of crystalline Silicon. However, it can be processed more easily into thin films suitable for solar cells. The target for amorphous Silicon is prepared to ensure a high consistency in film thickness up to several hundred nanometres. Empirical data indicate improvements in performance when well-deposited amorphous Silicon layers are applied.

Quality Control of Sputtering Targets

Sputtering targets are subjected to strict quality control. They are examined for microstructure, purity, uniformity of film thickness and adhesion properties. Standardised procedures are implemented to ensure that each batch of targets meets the criteria required for solar energy applications. The experience of many technicians and engineers has contributed to these established protocols. These measures are essential for any production line that aims to achieve high efficiency.

Long-term performance data indicate that the selection of appropriate sputtering target material can have a measurable impact on the final efficiency of solar cells. Research institutions and manufacturing facilities maintain data that support the use of high-quality targets. Given that advances in thin film deposition technology allow even small improvements in target material to result in significant gains in solar energy generation, continued attention to material quality is justified.

Conclusion

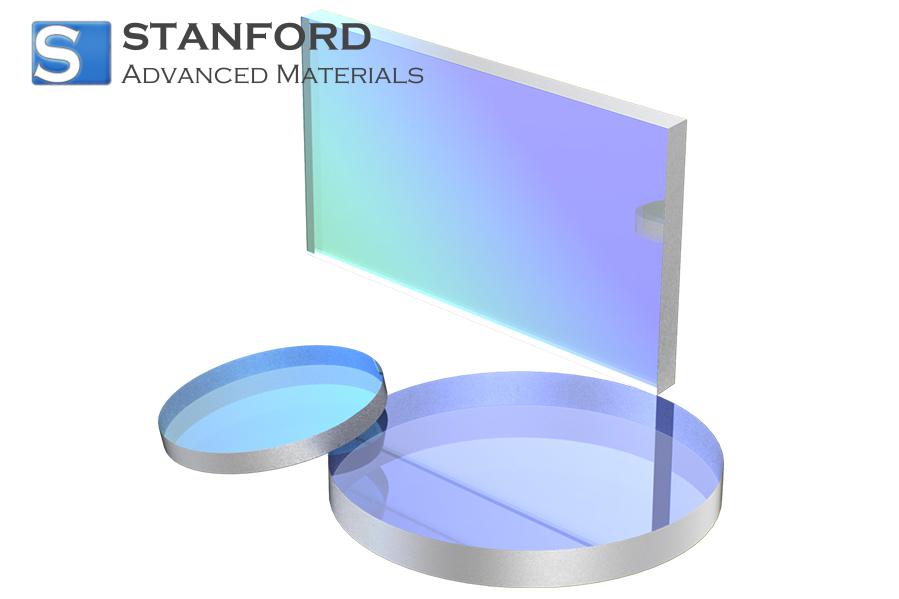

Sputtering targets occupy a central position in solar energy applications. They are essential for the deposition of high-quality thin films. In this article, high-purity materials such as Indium-Tin Oxide, aluminium-doped Zinc Oxide, Zinc Oxide and Copper-Indium-Gallium Diselenide have been discussed. These materials have been reliably used for several decades. Their properties and performance data clearly indicate their importance in practical applications. Further sputtering targets are available at Stanford Advanced Materials (SAM).

Frequently Asked Questions

Q: What is a sputtering target?

A: A sputtering target is a material used for the deposition of thin films in electronic components.

Q: How does sputtering contribute to solar energy generation?

A: Sputtering produces uniform, high-quality films that are essential for the efficient operation of solar cells.

Q: Are sputtering targets expensive?

A: They can be expensive, although improved technologies gradually reduce overall production costs.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento