Why Si₃N₄ Ceramic Balls Outlast Steel In Corrosive Environments

1. Chemical Stability and Corrosion Resistance

The fundamental advantage of Si₃N₄ ceramic balls lies in their exceptional chemical inertness. Steel, including stainless grades, relies on a thin passive oxide film for protection, which can be compromised by chlorides, acids, moisture, or high humidity, resulting in pitting and rapid corrosion. Once corrosion begins, the roughened surface concentrates stress and accelerates fatigue failure. Silicon nitride, in contrast, is a covalently bonded ceramic with no metallic phase and no dependency on protective films. It withstands attack from acids, alkalis, salts, and most solvents, forming a stable silica-rich surface layer in aggressive atmospheres. Consequently, corrosion progresses slowly, preserving surface quality and dimensional accuracy even after prolonged exposure.

2. No Rust, No Pitting, No Contamination

The absence of rust is one of the most evident reasons Si₃N₄ balls have a longer lifespan compared to steel. Steel corrosion generates rust particles that contaminate lubricants, increase friction, and act as abrasives that damage races and cages. This debris leads to vibration, noise, and premature bearing failure. Silicon nitride contains no iron and therefore cannot rust or pit in the conventional sense. Its surface remains clean, smooth, and chemically stable, preventing contamination of lubricants and surrounding components. This cleanliness is particularly valuable in precision systems such as semiconductor tools, medical devices, and high-speed spindles where even microscopic debris can disrupt performance.

3. Higher Hardness and Wear Resistance

Exceptional hardness provides Si₃N₄ ceramic balls with a significant durability advantage. With Vickers hardness typically between 1,400 and 1,700 HV, silicon nitride surpasses bearing steels in hardness and is highly resistant to abrasion, indentation, and micro-spalling. In corrosive environments, wear and corrosion often reinforce each other in a destructive process known as tribocorrosion. Steel surfaces weakened by corrosion are easily removed by contact stresses, exposing fresh metal to further attack. Silicon nitride largely avoids this cycle because it resists both chemical degradation and mechanical wear, resulting in a much slower material loss rate and significantly longer service life.

4. Low Friction and Favourable Tribological Behaviour

Lower friction is another key contributor to the extended life of Si₃N₄ balls. The dense, fine-grained microstructure of silicon nitride produces smooth rolling surfaces and a lower coefficient of friction than steel, particularly under boundary or mixed lubrication conditions. Reduced friction limits adhesive wear and minimises metal-to-metal contact in hybrid bearings. In corrosive or marginally lubricated systems, this behaviour reduces heat generation, slows lubricant breakdown, and suppresses corrosion-driven reactions. Over time, these effects translate into quieter operation, more stable running conditions, and markedly longer bearing life.

5. Thermal Stability and Resistance to High-Temperature Corrosion

High thermal stability enables Si₃N₄ balls to perform reliably where steel rapidly degrades. In hot, corrosive environments such as chemical reactors, kilns, and exhaust systems, steel loses hardness, oxidises more rapidly, and suffers dimensional changes from thermal expansion. Silicon nitride maintains high strength and hardness at elevated temperatures, exhibits low thermal expansion, and tolerates severe thermal shock without cracking. Its oxidation resistance remains effective even at high temperatures, preventing scale formation and surface damage. This combination makes Si₃N₄ ceramic balls suitable for applications where heat and corrosion act simultaneously to shorten the life of steel components.

6. Electrical Insulation and Protection Against Electrochemical Corrosion

Electrical insulation represents a decisive advantage in electrically active machinery. In motors and generators, stray currents passing through steel bearings lead to electrical pitting and fluting, a form of electrochemical corrosion that quickly damages rolling surfaces. Silicon nitride serves as an excellent electrical insulator, blocking current flow through the rolling elements and eliminating discharge damage at the contact points. By preventing electrical erosion altogether, Si₃N₄ ceramic balls can extend bearing life significantly in variable-frequency drives, high-speed spindles, and other electrically stressed systems.

7. Reduced Density and Lower Contact Stress

Lower density further enhances the durability of Si₃N₄ ceramic balls. Silicon nitride is approximately 40 per cent lighter than steel, which reduces centrifugal forces and contact stresses at high rotational speeds. Lower stresses slow crack initiation and fatigue propagation, particularly important in corrosive environments where surface integrity is already compromised. The integration of lighter weight and higher stiffness improves dynamic performance while directly extending fatigue life under aggressive operating conditions.

Conclusion

Si₃N₄ ceramic balls outperform steel in corrosive environments because they address corrosion, wear, heat, and electrical damage at their source. Their chemical inertness prevents rust and pitting, their hardness and low friction resist wear, and their thermal and electrical stability protect against high-temperature and electrochemical failure. Together with low density and contamination-free operation, these properties provide silicon nitride ceramic balls with a decisive and lasting advantage wherever steel bearings struggle to survive.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

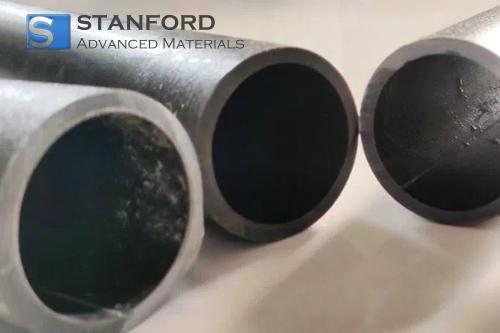

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento