Cemented Carbide Vs Tungsten Steel

For a long time, many assumed that cemented carbide is Tungsten Steel. In fact, quantitative differences exist between the two; consequently, this article examines the differences between cemented carbide and tungsten steel.

Cemented Carbide vs Tungsten Steel

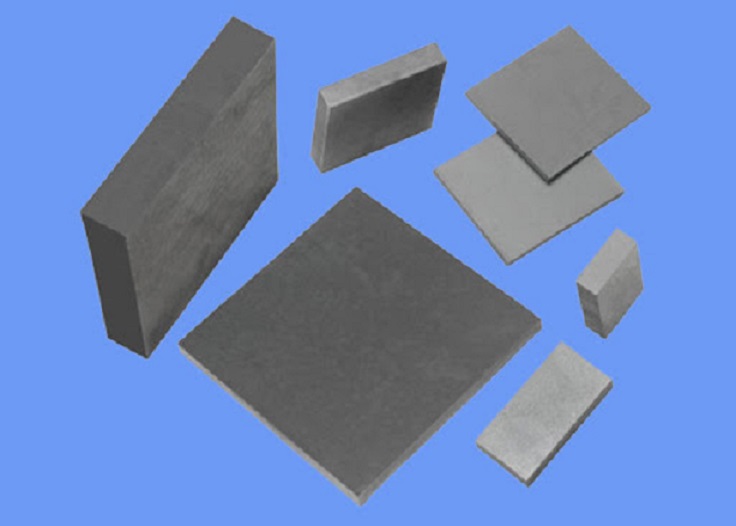

Cemented carbide is manufactured by sintering hard compounds of high-melting-point metals with binder metals using a powder metallurgy process. It is an alloy that maintains its hardness at 500°C and retains high hardness at 1 000°C. It exhibits high strength, good toughness and defined wear resistance.

The commonly used hardmetals are classified according to their composition and performance into three categories: tungsten–cobalt, tungsten–titanium–cobalt and tungsten–titanium–tantalum (niobium); among these, tungsten–cobalt and tungsten–titanium–cobalt are most frequently employed in production.

Tungsten steel, also recognised as tungsten–titanium alloy, high‑speed steel or tool steel, has a Vickers hardness rating of 10K and refers to a sintered composite material containing at least one metal carbide. Its main attributes are its high hardness and measurable wear resistance. It maintains high hardness at 1 000°C. The carbide component typically has a grain size between 0.2 and 10 micrometres.

Tungsten steel belongs to the category of cemented carbide; however, cemented carbide is not necessarily tungsten steel. Tungsten steel is produced by introducing tungsten raw materials into molten steel during the steel manufacturing process, with a tungsten content typically ranging from 15–25%. In contrast, cemented carbide is produced by sintering tungsten carbide with binder metals such as cobalt via powder metallurgy, and its tungsten content typically exceeds 80%.

In simple terms, any alloy with a hardness exceeding HRC65 can be classified as cemented carbide, thereby including tungsten steel; however, strictly speaking, cemented carbide does not necessarily imply tungsten steel.

Conclusion

Thank you for reading this article. We trust that it provides a clearer understanding of the differences between cemented carbide and tungsten steel. For further information, please visit Stanford Advanced Materials (SAM).

As a global supplier of tungsten products, Stanford Advanced Materials (SAM) has over 20 years of experience in the manufacture and sale of tungsten and tungsten steel. They supply tungsten products that meet the R&D and production requirements, and we are confident that SAM will be your preferred supplier and business partner for tungsten products.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

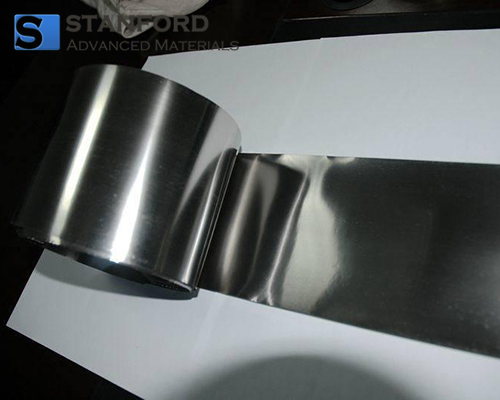

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento