Heating Furnaces For Crystal Growth Application

Introduction

As essential equipment in the crystallisation industry and other manufacturing sectors, heating furnaces provide a defined thermal environment for temperature control. By converting various forms of energy into heat and transferring this heat to materials by means of thermal radiation and convection, temperature variations during processes are accurately managed. In crystal growth and surface deposition, precise temperature control directly affects the quality of the final product. A detailed introduction to the role of the furnace in these processes can assist in resolving uncertainties regarding the selection of heating furnace equipment. If necessary, consult the advisers at Stanford Advanced Materials (SAM).

1. Melt Growth Methods

1.1 Czochralski Method

The Czochralski method (CZ method) is a principal technique for the growth of monocrystalline silicon and other single-crystal materials. The furnace is used to provide the high-temperature environment required to maintain the uniformity and stability of the molten material, which in turn directly affects the quality of the finished crystal.

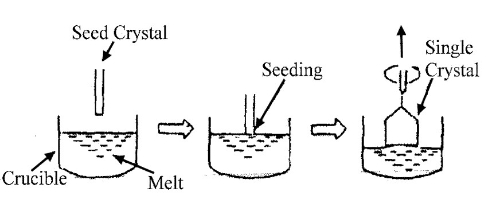

The basic steps of the Czochralski process include melting the initial material, for instance by heating polysilicon until it is fully liquefied. Thereafter, crystallisation is initiated by contacting the molten surface with a thin rod (seed crystal) and gradually extracting the crystal from the melt through controlled rotation and withdrawal. By precisely regulating the pulling and rotation speeds during crystal growth, single crystals are gradually produced.

Fig. 1 Process of the Czochralski method

The functions of the furnace in the CZ method include:

1. Provision of a stable high‐temperature environment:

Temperature control: The furnace must operate stably at high temperatures exceeding 1 400 °C and is typically regulated to approximately 1 500 °C to ensure the molten state of materials such as silicon is maintained.

Uniform heating: To avoid temperature gradients within the melt, the furnace should supply a uniform heating environment to maintain constant temperature throughout the crystal growth period.

2. Maintenance of the purity of the melt:

Crucible material: Crucibles are normally manufactured from high-purity quartz or other inert materials so that no contaminants enter the melt.

Atmosphere control: The use of a protective atmosphere (for example, argon) or vacuum minimises oxidation and other gas-phase reactions that may affect crystal growth.

3. Design of the thermal field:

Configuration of the thermal field: By optimising the position of the heating elements and the arrangement of insulation around the crucible, the distribution of the thermal field may be precisely controlled. This has a direct effect on the flow and temperature distribution of the melt and, consequently, on the crystal growth rate and quality.

Control of the thermal gradient: During crystal growth, the furnace must maintain an appropriate temperature gradient to promote unidirectional crystal growth and reduce defects.

4. Dynamic temperature adjustment:

During crystal pulling: As crystals are withdrawn from the melt, the furnace adjusts the temperature in response to changes in growth rate and crystal diameter, thereby ensuring stable growth and uniform crystal shape.

Crystallisation and annealing: Upon completion of crystal growth, the furnace gradually lowers the temperature for the annealing process to reduce internal stresses and defects, thus improving the mechanical and electrical properties of the crystals.

The most commonly employed furnace types in the CZ method are resistance furnaces and induction furnaces. Most CZ crystal growth systems utilise resistance furnaces due to their high temperature regulation accuracy and simple construction. Typical heating elements include graphite and molybdenum wires, ensuring stable and uniform heating. In contrast, induction furnaces enable rapid heating and cooling for processes that require rapid temperature changes. The generation of uniform eddy current heating within the crucible via electromagnetic induction contributes to stable temperature maintenance of the melt. Fig. 6 and Fig. 7 illustrate the construction of vertical and horizontal heating furnaces, respectively.

Example Analysis

1. Growth of silicon single crystals: In the semiconductor industry, the CZ process is routinely employed to produce high-purity silicon single crystals that serve as the base material for integrated circuits. The furnace provides a precisely controlled high-temperature environment during this process to ensure the purity and uniformity of the silicon melt, thereby producing defect-free, large-scale single crystals.

2. Growth of oxide single crystals: The CZ method is also employed to produce oxide single crystals (for example, sapphire) that are critical in optical and electronic applications. The high-temperature stability of the furnace and its control over the temperature gradient are vital in minimising stresses and defects within the crystals.

1.2 Bridgman Method

In the Bridgman method, polycrystalline or high-purity powdered material is loaded into a crucible that is heated in a furnace until the material is molten. Subsequently, the molten material is cooled gradually and crystal growth is initiated by either moving the crucible slowly or by establishing a temperature gradient within the furnace, eventually leading to the formation of single crystals from seed crystals.

The furnace in the Bridgman method performs the following functions:

1. Provision of a stable high‐temperature environment:

Molten material: The furnace must operate reliably at high temperatures in order to completely melt the material. For example, silicon crystal growth requires temperatures exceeding 1 414 °C, while the growth of molybdenum crystals requires temperatures over 2 623 °C.

Uniform temperature: The furnace must provide even heating to stabilise the melting temperature and avoid fluctuations that could adversely affect crystal growth.

2. Control of temperature gradients:

Hot and cold zones: The design of the furnace must be capable of creating distinct hot and cold zones. Typically, the hot zone is located at the upper part of the crucible, while the cold zone is at the lower end or within the growth region.

Adjustment of the thermal gradient: Through modifying the power and position of the heating elements, both the magnitude and location of the temperature gradient can be controlled. This has a direct influence on the crystal growth rate and quality.

3. Dynamic temperature regulation:

Movement of the crucible: In the Bridgman method the crucible is typically moved downward at a constant speed, so that the molten material gradually crystallises while traversing the temperature gradient zone. The furnace must maintain stable temperature control throughout this movement.

Directed solidification: The furnace ensures the material solidifies directionally from the melt zone to the solid zone, thereby reducing crystal defects and internal stresses.

4. Preservation of melt purity:

Crucible selection: The crucible must consist of inert and high-temperature-resistant materials such as quartz, graphite, or platinum to avoid contaminating the melt.

Atmosphere control: Within the furnace, an inert atmosphere (for example, argon) or vacuum is maintained to prevent oxidation and contamination of the melt and to ensure crystal purity.

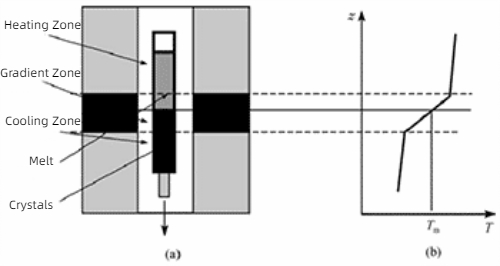

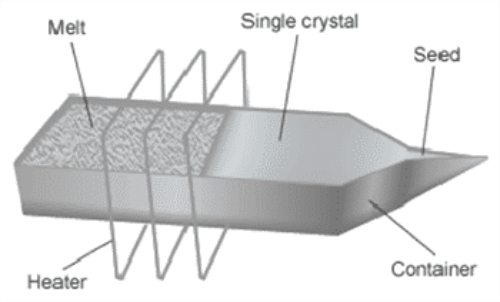

In the Bridgman process, vertical and horizontal furnaces are predominantly used. Vertical furnaces typically include heating elements arranged in upper and lower zones that permit precise temperature control in each zone, meeting the demands of the required thermal gradient for Bridgman crystal growth. Horizontal furnaces are designed for lateral thermal gradient control by moving the crucible sideways. They are utilised for the growth of certain materials, such as some high-temperature superconductors and metallic crystals.

Fig. 2 Schematic of a vertical furnace and temperature distribution

Fig. 3 Schematic representation of the horizontal Bridgman growth setup

Example Analysis

1. Growth of CdTe crystals: Cadmium telluride (CdTe) crystals are used in photodetectors and solar cells. In the Bridgman process, a furnace is required to melt CdTe at approximately 1 092 °C and to create a precise temperature gradient during slow cooling, thereby producing high-quality single crystals.

2. Growth of silicon crystals: High-purity silicon crystals are indispensable for electronic and optoelectronic devices. In Bridgman crystal growth of silicon, the furnace must maintain temperatures above 1 414 °C and ensure the appropriate temperature gradient to facilitate directional solidification and reduce defects.

2. Chemical Vapour Deposition (CVD)

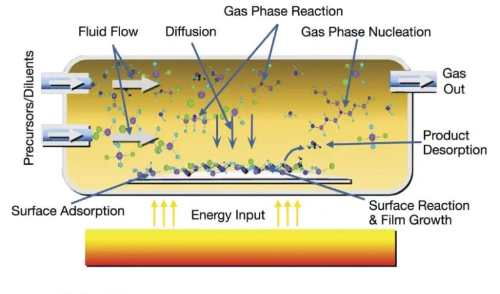

Chemical Vapour Deposition (CVD) is a widely used technique for fabricating high-performance films and coatings. The furnace plays a key role in the CVD process by establishing the necessary temperature conditions to facilitate the chemical reaction of the vapor-phase reactants on the substrate surface, thereby forming the desired film.

Fundamental steps in the CVD process involve introducing gaseous precursors into a reaction chamber, where the substrate is heated to an elevated temperature to promote the chemical reaction. The gaseous precursor reacts chemically on the substrate surface and forms a solid film, while the reaction by-products are then evacuated from the chamber.

Fig. 4 Principle of CVD

The functions of the heating system in CVD include:

1. Provision of the reaction temperature:

Substrate heating: The furnace heats the substrate to the required reaction temperature, which typically ranges between 200 °C and 1 200 °C depending on the deposited material and process requirements.

Heating of the reaction zone: The furnace maintains the temperature of the reaction zone to ensure that the gas-phase reactants effectively react at the substrate surface.

2. Facilitation of the chemical reaction:

Reaction kinetics: Temperature is a key factor affecting the kinetics of chemical reactions. By regulating the temperature, the furnace optimises the decomposition and reaction rates of the precursor compounds, thereby enhancing both the deposition efficiency and film quality.

Control of film characteristics: Different deposition temperatures can influence film properties such as crystal structure, composition and stress. Precise temperature control assists in achieving specific film characteristics.

3. Ensuring uniform deposition:

Temperature uniformity: The furnace must provide a consistent temperature distribution to ensure uniform film thickness and composition while avoiding inhomogeneities and defects.

Dynamic temperature adjustment: During deposition, the temperature is adjusted according to various phases and process requirements; the furnace should demonstrate a prompt dynamic response.

Typically, tube furnaces, chamber furnaces and induction furnaces are used for CVD. Tube furnaces are generally constructed from long quartz or ceramic tubes in which the substrate is positioned and heated by an external heating element. They are suitable for small-scale and laboratory CVD processes and offer good temperature and atmosphere control. Chamber furnaces resemble conventional furnaces with an internal heating chamber where the substrate and precursor react. Chamber furnaces are applicable for processing large substrates and mass production, providing a uniform temperature environment and high throughput. Induction furnaces utilise electromagnetic induction to heat substrates and are generally used in processes that require rapid heating and cooling. Their ability to heat quickly makes them suitable for high-temperature and short-duration deposition processes and they typically require less substrate material.

Example Analysis

1. Deposition of silicides: CVD deposition of silicide layers is generally conducted at elevated temperatures (approximately 600–900 °C). The furnace provides the necessary thermal environment to ensure that precursors (for example, silane and metal-organic compounds) react efficiently to form a homogeneous silicide film.

2. Deposition of diamond thin films: CVD deposition of diamond is typically performed at temperatures between 900 °C and 1 200 °C. The furnace maintains the temperature necessary for methane and hydrogen precursors to form diamond-based crystal structures on the substrate.

3. Deposition of gallium nitride thin films: CVD deposition of gallium nitride requires temperatures of approximately 1 000 °C. The furnace ensures that ammonia and gallium precursors react to produce high-quality GaN films.

3. Molecular Beam Epitaxy (MBE)

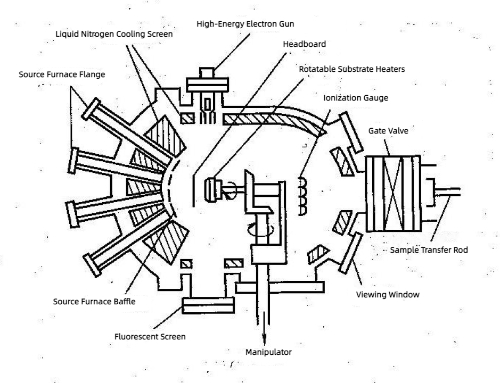

Molecular Beam Epitaxy (MBE) is a precisely controlled technique for the production of thin films with high purity and low defect densities, as well as other functional layers. A heated furnace plays a key role in the MBE process by providing the necessary temperature control for the evaporation of source materials and by precisely regulating the substrate temperature for high-quality epitaxial film deposition.

In MBE technology, epitaxial thin films are produced by evaporating atomic or molecular beams from the source material onto the substrate surface in a high or ultrahigh vacuum environment. The fundamental steps include generating molecular beams by heating the source material, thereby causing it to evaporate or sublime, heating the substrate to the required temperature to facilitate film growth, and controlling the flux of the molecular beam and substrate temperature to achieve an accurate deposition of the epitaxial layer.

Fig. 9 Schematic layout of the MBE growth chamber

The functions of the heating system in MBE include:

1. Heating of the source material:

Evaporation source: The furnace is used to heat the source material (for example, gallium arsenide, silicon, aluminium, etc.) to induce evaporation or sublimation under vacuum and produce a uniform atomic or molecular beam.

Temperature control: Evaporation temperatures vary depending on the material, typically between 500 °C and 1 500 °C. The furnace regulates the evaporation process temperature to ensure a stable evaporation rate and vapor flux density.

2. Heating of the substrate:

Temperature regulation: The substrate temperature is critical for determining the crystal structure and quality of the epitaxial film. The furnace heats the substrate to a designated temperature, typically between 200 °C and 800 °C, to promote atomic migration and alignment on the substrate surface, thereby enabling the formation of a high-quality epitaxial film.

Uniformity: The furnace must ensure even substrate heating to avoid temperature gradients that could lead to variations in film thickness or crystal defects.

3. Control of thermal deposition:

Heating from multiple sources: MBE systems are generally equipped with several furnaces to heat different source materials. Coordinated temperature control of these furnaces is essential for the accurate deposition of multilayer or alloy structures.

Dynamic adjustment: During the deposition process, the furnace temperature may be adjusted in real time to optimise the film’s properties according to current growth conditions.

In processes involving both heating for evaporation of the source material and maintenance of substrate temperature during deposition, various heating devices are used. The Knudsen cell (K-cell), a common evaporation source in MBE, contains the source material and is heated either by resistance or electron-beam methods. It provides a stable evaporation rate with precise temperature control and is suitable for the epitaxial growth of high-purity materials. Another type of heating device employed for source evaporation is the electron-beam furnace. The electron-beam furnace uses an electron beam to heat the surface of the source material to its evaporation temperature, making it suitable for high-melting-point materials due to its high heating power and rapid temperature response.

In contrast, substrate heating is usually integrated into the sample holder of the MBE system, heating the substrate via resistance or radiative methods. Substrate heaters offer precise temperature control and a uniform heating environment for a range of substrate materials and deposition requirements.

Example Analysis

1. Epitaxial growth of GaAs (gallium arsenide): During the MBE growth of GaAs thin films, the heating system is used to bring the arsenic and gallium source materials to their respective evaporation temperatures (approximately 400–600 °C and 1 200–1 500 °C) and to heat the substrate to around 600 °C, thereby facilitating the formation of high-quality GaAs epitaxial films.

2. AlGaAs/GaAs multilayer structures: Multiple furnaces in the MBE system heat the aluminium, gallium and arsenic source materials separately to achieve an accurate deposition of AlGaAs/GaAs multilayer structures through precise control of the evaporation rates and substrate temperature.

Conclusion

Heating furnaces perform a central function in various crystal growth processes such as the Czochralski method, the Bridgman method, Chemical Vapour Deposition (CVD) and Molecular Beam Epitaxy (MBE). Their ability to establish stable high-temperature environments, maintain melt purity, control temperature gradients and dynamically adjust temperatures is critical for the production of high-quality single crystals. Whether for use in the semiconductor industry for silicon single crystals or for the production of oxide single crystals, heating furnaces ensure precision and consistency. Understanding the specific process parameters and capabilities of various furnace types enables informed decisions to be made to achieve optimal results in crystal growth. For reliable and high-grade muffle furnaces, Stanford Advanced Materials (SAM) provides a range of options tailored to meet specific requirements.

References:

[1] R. R. Gilman, Czochralski and Floating Zone Crystal Growth of Modern Materials, Springer, 2012.

[2] G. Müller, "Handbook of Crystal Growth: Bulk Crystal Growth", Elsevier, 2014.

[3] Guo Qin-Min, Qin Zhi-Hui. Development and Application of Evaporation Technology in Atomic Fabrication. Acta Phys. Sin., 2021, 70(2): 028101. doi: 10.7498/aps.70.20201436

[4] R. F. C. Farrow, "Molecular Beam Epitaxy: Applications to Key Materials", Noyes Publications, 1995.

[5] L. L. Chang and K. Ploog, "Molecular Beam Epitaxy and Heterostructures", Springer, 2013.

[6] Lech Pawlowski, "The Science and Engineering of Thermal Spray Coatings", John Wiley & Sons, 2008.

[7] Robert C. Tucker Jr., "Thermal Spray Technology", ASM Handbook, Volume 5A, ASM International, 2013.

[8] Gerd W. Becker, "Industrial Furnaces: Heat Treatment Equipment", Wiley-VCH, 2014.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento