Introduction To Heating Furnace: Principle, Types & Applications

Heating furnaces are indispensable in various industrial sectors, including the crystallisation and processing industries, where precise temperature regulation is critical. These furnaces convert different forms of energy into heat and transfer it to the materials through thermal radiation and convection. Temperature control in processes such as crystal growth and surface deposition has a direct effect on product quality. This article explains the fundamental principles of heating furnaces and presents several types with their specific features and applications. Familiarity with these types assists in selecting the most appropriate furnace for specific industrial requirements.

Basic Principle of the Heating Furnace

The basic principle of a heating furnace comprises: 1) the conversion of electrical energy into thermal energy through resistance heating, induction heating or radiant heating; or 2) the conversion of chemical energy into thermal energy through fuel combustion, followed by the uniform transfer of heat to the material.

The heating furnace is equipped with an internal combustion device for the combustion of fuel to produce high‐temperature exhaust gases. The exhaust gases are discharged via a chimney, and the waste heat may be used to preheat the air entering the combustion chamber, thereby improving the thermal efficiency. The furnace may also be fitted with an automatic control and monitoring system to accurately regulate both the temperature and the duration of the heating process. Continuous furnaces are generally fuelled by gas, heavy oil or coal dust, and sometimes by lump coal. To effectively utilise the heat from the exhaust gases, heat exchangers are installed to preheat the air and gas within the flue, or exhaust heat boilers are provided.

In forging and rolling production, the billets are typically heated in an oxidising atmosphere with a full combustion flame. The use of incomplete combustion to generate a reducing flame (i.e. a "self-protecting atmosphere") permits direct metal heating with minimal oxidation. This method, known as non-oxidising open-flame heating, is applied in rotary hearth furnaces and chamber furnaces.

The general construction of a heating furnace is determined by the temperature distribution within the furnace. The furnace length is divided into a preheating zone, a heating zone and a zone for uniform heating. The preheating section operates at a lower temperature and utilises the furnace gas heat to improve thermal efficiency. The heating section is the primary zone, where a higher furnace gas temperature facilitates rapid heating. The temperature difference between the furnace gas and the metal is kept to a minimum to ensure that the billets exit the furnace at a uniform temperature.

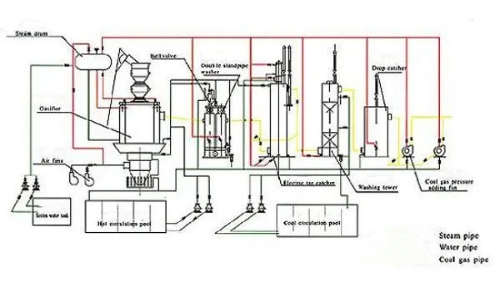

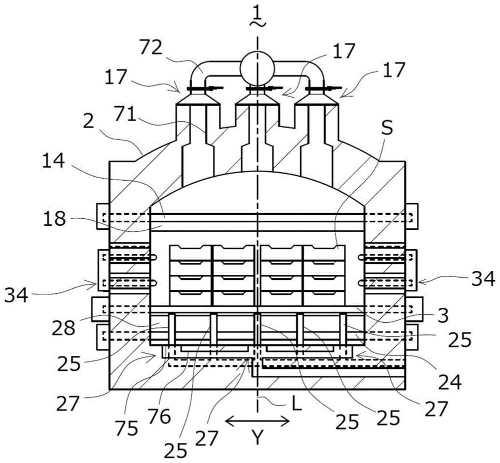

Fig. 1 Structure and Principle of a Vacuum Heating Furnace

Types of Heating Furnaces and Their Characteristics

The most common classification is based on the form and application of the heating furnace and distinguishes between continuous furnaces and chamber furnaces. Each category is further subdivided into specific types.

Continuous Heating Furnace

Most continuous heating furnaces are used for heating metal billets prior to rolling, and a few are employed in forging and heat treatment. The key feature is that billets are continuously introduced into the furnace in line with the rolling rhythm, while furnace gas flows continuously. Typically, the charge size, type and yield remain constant. The temperature of both the furnace and the metallic material does not vary over time but only changes along the furnace length.

Fig. 2 A Continuous Furnace for Stacked Saggars

Continuous heating furnaces include shock furnaces, step furnaces, rotary hearth furnaces and chamber furnaces. Among these, shock furnaces are frequently referenced in discussions of continuous furnaces.

1. Shock Continuous Heating Furnace

A shock continuous furnace operates by pushing the steel billets to transport the material into the furnace while maintaining continuous heating. The billets are pushed along the furnace floor or on sleds supported by water-cooled tubes; in the latter case, both sides of the billets are heated. The water tubes at the furnace base are usually covered with insulating material to minimise heat loss. To reduce the "black spots" caused by the lower portions of the billets contacting the refractory lining, this furnace is known as a "water-cooled furnace."

2. Step Continuous Heating Furnace

In a step continuous furnace, the billets are advanced in stages, supported either on the furnace floor or on water-cooled metal beams. This stepwise movement involves forward, downward and backward motions to transport the billets through the furnace. There are two main types of these furnaces:

- Stufenboden Furnace: A furnace with a fixed bottom and a stepped floor.

- Furnace with Stepped Beam: A furnace with a fixed beam and a stepped beam.

Compared with the shock furnace, this design offers the following advantages: 1) more flexible material transport, permitting the entire furnace load to be discharged if necessary; 2) billets on the furnace floor or beams are heated more rapidly and uniformly; 3) bulging and adhesion issues encountered in shock furnaces are eliminated, so that the furnace length is not limited by these factors.

3. Rotary Hearth Heating Furnace

A rotary hearth furnace consists of a fixed furnace body with a rotating hearth. The billets placed on the rotating hearth progress from the inlet to the outlet as the hearth turns. Depending on the shape of the hearth, these furnaces are classified into the following categories:

- Ring Furnace: Commonly used in foundries.

- Disc-shaped Furnace

The rotary hearth ring furnace has a production capacity of approximately 75 tonnes per hour. This furnace type is suited for heating materials that cannot be transported by the shock or step methods, such as round billets, wheel and rim billets, preformed die-forged billets and various other billet types and lengths.

A disadvantage is the low utilisation of the furnace hearth area, with a typical floor production rate of 350 to 400 kg/m² per hour.

4. Chamber Rapid Heating Furnace

A chamber rapid heating furnace comprises several heating chambers arranged in series. Each chamber is separated by transfer spaces equipped with billet rollers. The billets, whether single or double, pass through these heating chambers and transfer spaces and are heated throughout the process. Each heating chamber and its adjacent chamber form an "oven section", which is why this furnace is also known as a sectional furnace.

This furnace type permits rapid heating with low oxidation and decarburisation and is suitable for heating round billets and steel pipes. In conjunction with a planetary mill, it can heat continuous casting slabs; it may also be deployed for the local heating of specific steels.

The disadvantage is the low production capacity of the furnace unit and its low thermal efficiency.

Chamber Heating Furnaces

Chamber heating furnaces are used for heating metal billets or blocks prior to forging. The material remains stationary during heating. The furnace is not segmented and requires uniform temperature distribution throughout, especially for large billet heating using a cyclic temperature system (i.e. the furnace temperature is divided into preheating, heating periods and designated time intervals).

Fig. 3 A Type of Large Chamber Heating Furnace

Two types of chamber heating furnaces exist: those with a fixed floor and those with a wagon floor.

1. Chamber Furnace with Fixed Floor

The furnace floor area typically ranges from 1 to 10 m². Charging is usually performed manually or with simple machinery. Furnaces designed for heating larger workpieces may be equipped with dedicated charging machines. They are fuelled by coal, heavy oil or gas. Some furnaces feature openings in the furnace wall through which billets are inserted for heating; these are known as "seam furnaces" and are often used for heating small batches or for the local heating of long billets. The floor production rate is generally 300 to 400 kg/(m²·hour), and the unit heat consumption per tonne of steel is approximately (1,0 to 1,5) × 10⁶ kcal.

2. Wagon Floor Furnace

This furnace is employed in a forge for large ingots weighing from more than ten tonnes up to several hundred tonnes, whether of the chamber or tunnel type. The heated objects are placed on a wagon and loaded or unloaded outside the furnace using a workshop crane or other traction devices, thereby pulling the wagon into or out of the furnace. The furnace meets the requirement for uniform temperature distribution in large ingot heating; consequently, the auto-wagon floor furnace is often used for decentralised heating and decentralised exhaust extraction, with burners and exhaust outlets distributed along the furnace sidewalls.

Other Classification Factors

Heating furnaces can also be classified based on various factors beyond the basic types of continuous and chamber furnaces. These classifications include:

1. Construction of the furnace: Based on the external shape of the furnace, including box furnaces, sloping roof furnaces, cylindrical furnaces and vertical furnaces.

2. Process application: Based on specific industrial applications, including atmospheric furnaces, decompression furnaces, catalytic furnaces, coke furnaces, hydrogen furnaces and asphalt furnaces.

3. Method of heat transfer: Based on the type of heat transfer, including purely radiant furnaces, purely convective furnaces and convection–radiation furnaces.

4. Heating methods: Based on the heating method used, including single-sided radiant furnaces and double-sided radiant furnaces.

5. Form of combustion and air supply: Based on the combustion and air supply methods, including furnaces with bottom firing, side firing, forced air and natural air supply.

6. Fuel used: Based on the type of fuel, including oil burners, gas burners and dual-fuel burners.

7. Special types: Based on special purposes or operating environments, including lift heating furnaces, heat treatment furnaces, Vacuum Furnaces and atmospheric furnaces.

Conclusion

Heating furnaces are essential in industries that require precise temperature regulation, such as the crystallisation and various processing industries. An understanding of the fundamental principles, types and characteristics of heating furnaces assists in selecting the appropriate equipment for specific applications. Whether continuous or chamber furnaces are used, the choice of furnace affects the efficiency and quality of the heating process. Detailed advice and technical expertise can be obtained from experts at Stanford Advanced Materials (SAM), who can support the decision-making process.

References:

[1] R. R. Gilman, Czochralski and Floating Zone Crystal Growth of Modern Materials, Springer, 2012.

[2] G. Müller, "Handbook of Crystal Growth: Bulk Crystal Growth", Elsevier, 2014.

[3] Guo Qin-Min, Qin Zhi-Hui. Entwicklung und Anwendung der Aufdampfungstechnologie in der atomaren Fertigung. Acta Phys. Sin., 2021, 70(2): 028101. doi: 10.7498/aps.70.20201436

[4] R. F. C. Farrow, "Molecular Beam Epitaxy: Applications to Key Materials", Noyes Publications, 1995.

[5] L. L. Chang und K. Ploog, "Molecular Beam Epitaxy and Heterostructures", Springer, 2013.

[6] Lech Pawlowski, "The Science and Engineering of Thermal Spray Coatings", John Wiley & Sons, 2008.

[7] Robert C. Tucker Jr., "Thermal Spray Technology", ASM Handbook, Band 5A, ASM International, 2013.

[8] Gerd W. Becker, "Industrial Furnaces: Wärmebehandlungsanlagen", Wiley-VCH, 2014.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento