Heating Furnaces For Surface Deposition Application

Introduction

Heating Furnaces are necessary in Physical Vapour Deposition (PVD) and Thermal Spraying (TSP) surface coating processes. These processes produce thin films and coatings by transferring material from a source to a substrate. In PVD, techniques such as evaporation, sputtering and pulsed laser deposition depend on precise temperature regulation provided by heating furnaces to achieve high‐quality film deposition. Similarly, heating furnaces are required in TSP to heat the feed material to a molten or semi‐molten state, thereby facilitating the formation of dense, uniform coatings. This article investigates the role of heating furnaces in both PVD and TSP processes, emphasising their function in temperature regulation, material transfer and control of film properties.

Physical Vapour Deposition (PVD)

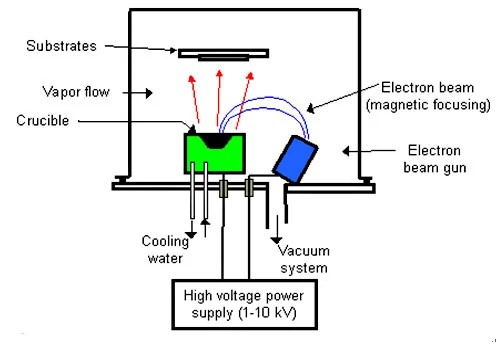

Physical Vapour Deposition (PVD) is a technique for the production of thin films and coatings by means of the physical transfer of material from a source to a substrate. PVD methods include evaporation, sputtering and pulsed laser deposition. A heating furnace plays a key role in the PVD process, as it provides the required temperature control to facilitate the evaporation or sputtering of the material, thereby ensuring a high‐quality film deposition.

PVD utilises a physical process to transfer material from a source to a substrate. The fundamental steps involve heating the source material, evaporating or sputtering it to generate vapour‐phase particles, transferring the particles onto the substrate surface in a vacuum or low‐pressure environment, and finally condensing the particles on the substrate to form a thin film.

Fig. 1 Schematic diagram of the PVD process

The functions of the heating furnace in the PVD process include:

1. Provision of the evaporation temperature:

Evaporation source: The furnace is used to heat the source material until it reaches the evaporation temperature and produces vapour. The evaporation temperature varies with the material, generally between 500°C and 3 000°C.

Temperature regulation: The furnace requires precise temperature control to ensure a stable evaporation rate and uniform vapour flux density.

2. Facilitating the sputtering process:

Target heating: In some sputtering methods, heating furnaces are employed to preheat the target so that it becomes more receptive to ion bombardment in order to generate vapour‐phase particles.

Substrate heating: Heating the substrate aids in enhancing film adhesion and crystallisation quality. Typical substrate temperatures range from 100°C to 800°C, depending on the material and the application requirements.

3. Control of the film properties:

Film structure: Temperature has a significant influence on the crystallographic structure, density and internal stress of the film. With precise temperature control, the film structure and its properties can be optimised.

Stress control: Furnaces may be utilised to reduce internal stresses in the film by regulating the substrate temperature, thereby preventing crack formation and delamination.

A resistance‐heated furnace with a resistance wire heating element is commonly employed in PVD and can be used for both the evaporation source and the substrate. It offers precise temperature regulation and is suitable for most PVD applications. Electron beam furnaces use an electron beam to heat the surface of the source material to the evaporation temperature. They are applicable for materials with high melting points, provide high heating power and exhibit a rapid temperature response. In addition, induction furnaces utilise electromagnetic induction to heat the source material or substrate. They operate rapidly and are suitable for processes requiring quick heating and cooling.

Example analysis

1. Thermal evaporation: This method is used for depositing metal films, semiconductor materials and organic substances. The source material (e.g. Gold, Aluminium, Silicon) is heated in a furnace until evaporation occurs, followed by deposition onto a substrate as a thin film. Typical temperatures range from 600°C to 1 500°C. 2.

2. Electron beam evaporation: Electron beam evaporation is utilised for depositing thin films of materials with high melting points such as tungsten, molybdenum and ceramic materials. An electron beam heats the source material to the required high temperatures for evaporation. Precise furnace temperature control ensures the formation of quality films.

3. Sputter deposition: Sputter deposition is widely used in the manufacture of optical coatings, semiconductor components and wear‐resistant films. Furnaces are employed to heat both the target and the substrate to improve sputter efficiency and film quality. The substrate is typically heated to temperatures between 100°C and 500°C, which facilitates crystallisation and enhances film adhesion.

Thermal Spraying

Thermal Spraying (TSP) is a process for producing a coating by heating a feed material and accelerating it until it impacts a substrate surface. A heating furnace plays a key role in thermal spraying as it provides the required thermal energy to heat the sprayed material to a molten or semi‐molten state, thereby ensuring a high‐quality coating.

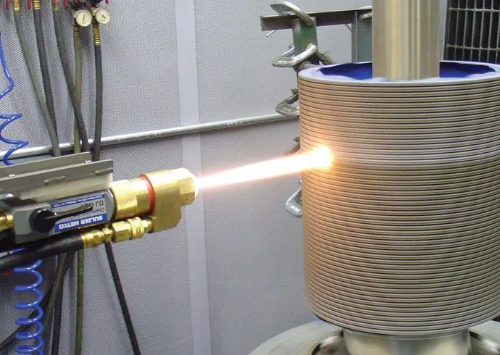

In thermal spraying, a powder or wire feedstock is heated to a molten or semi‐molten state and sprayed at high speed onto a substrate surface to form a coating. The fundamental steps include heating the feed material, accelerating the molten particles using a high‐pressure gas stream or an electric arc, and then cooling and solidifying the particles on the substrate to form a dense coating.

Fig. 2 Thermal Spraying Process

The functions of the heating furnace in thermal spraying include:

1. Providing the melting temperature:

Material heating: The furnace heats the coating material to a molten or semi‐molten state, usually within the range of 1 000°C to 3 000°C.

Temperature regulation: The heating temperature is controlled accurately to ensure that the material attains the correct flow behaviour and adhesion required for forming an even coating.

2. Facilitating particle acceleration:

Efficient energy transfer: The furnace delivers high energy so that the molten material particles receive sufficient kinetic energy to impact the substrate at high speed.

Uniform heating: The material particles are heated uniformly, thereby preventing coating defects caused by temperature inhomogeneities.

3. Control of the coating properties:

Coating structure: The furnace influences the microstructure and the macroscopic properties of the coating through adjustments of temperature and spraying parameters.

Coating characteristics: Optimisation of the heating process results in improved mechanical properties, corrosion resistance and thermal stability of the coating.

Thermal spraying is classified according to the heating method employed into arc spraying, flame spraying, plasma spraying and high‐frequency induction spraying.

1. Arc spraying: An arc discharge generates high temperatures (approximately 3 000°C) which melt the material. The molten material (e.g. Zinc and Aluminium) is sprayed onto the substrate to form a dense protective coating. This method is suitable for metal and alloy materials and is used in corrosion protection, conductive and wear‐resistant coatings.

2. Flame spraying: In flame spraying, the material is heated by a flame produced by the combustion of gaseous fuels (e.g. acetylene, hydrogen) with oxygen. The heated material is sprayed onto the substrate to produce an even coating. This process is simple and suitable for the rapid coating of large areas. It is applicable to metal, ceramic and polymer coatings and is frequently adopted for the repair and reinforcement of mechanical parts.

3. Plasma spraying: Plasma spraying utilises a high‐temperature plasma (up to 10 000°C) generated by arc heating to melt the material. The molten material is then sprayed at high speed onto the substrate, resulting in a coating with high density and good adhesion. This method is applicable for materials with high melting points, such as ceramics, and is employed for high‐temperature protection, wear‐resistant and biomedical coatings.

Fig. 3 Plasma spraying system

4. High‐frequency induction spraying: In this process, the wire is heated by a high‐frequency electromagnetic field until it melts, and then sprayed onto the substrate to produce a coating. High‐frequency induction heating offers rapid heating and precise temperature control. It is suitable for materials that require fast heating and is used for the production of high‐strength, wear‐resistant coatings.

Conclusion

Heating furnaces are indispensable for the success of PVD processes. They provide the necessary temperature control during evaporation, sputtering and other material transfer methods, and directly affect the quality of the deposited thin films. Maintaining precise temperature conditions results in stable evaporation rates, a uniform vapour flux and optimised film properties such as crystallographic structure, density and stress levels. Stanford Advanced Materials (SAM) supplies a range of muffle furnaces that fulfil the specific requirements of PVD applications, thereby facilitating the attainment of coating outcomes that meet industry standards.

References:

[1] R. R. Gilman, Czochralski and Floating Zone Crystal Growth of Modern Materials, Springer, 2012.

[2] G. Müller, "Handbook of Crystal Growth: Bulk Crystal Growth", Elsevier, 2014.

[3] Guo Qin-Min, Qin Zhi-Hui. Entwicklung und Anwendung der Aufdampfungstechnologie in der atomaren Fertigung. Acta Phys. Sin., 2021, 70(2): 028101. doi: 10.7498/aps.70.20201436

[4] R. F. C. Farrow, "Molecular Beam Epitaxy: Applications to Key Materials", Noyes Publications, 1995.

[5] L. L. Chang und K. Ploog, "Molecular Beam Epitaxy and Heterostructures", Springer, 2013.

[6] Lech Pawlowski, "The Science and Engineering of Thermal Spray Coatings", John Wiley & Sons, 2008.

[7] Robert C. Tucker Jr., "Thermal Spray Technology", ASM Handbook, Band 5A, ASM International, 2013.

[8] Gerd W. Becker, "Industrial Furnaces: Wärmebehandlungsanlagen", Wiley-VCH, 2014.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento