Rachel Monroe leads the quality assurance team at Stanford Advanced Materials. With over 15 years in industrial material inspection and testing, she ensures every batch meets performance, compliance, and safety standards. Her work connects lab testing with customer satisfaction, bridging quality metrics and real-world reliability.

How to Store Sputtering Targets Properly: Moisture Protection and Best Practices

Sputtering targets may appear stable at first glance, but improper storage—particularly exposure to moisture—can lead to serious degradation: cracking, oxidation, contamination, and ultimately compromised performance in thin film deposition.

Highly engineered ceramics or metals can degrade due to long-term exposure to ambient air. The damage often begins invisibly, and by the time defects are observed, the target may already be unusable.

Why Proper Storage Matters

Sputtering targets are not everyday raw materials—they are precision-engineered, often fragile, and sometimes chemically reactive. A clean storage shelf alone is insufficient to guarantee their longevity.

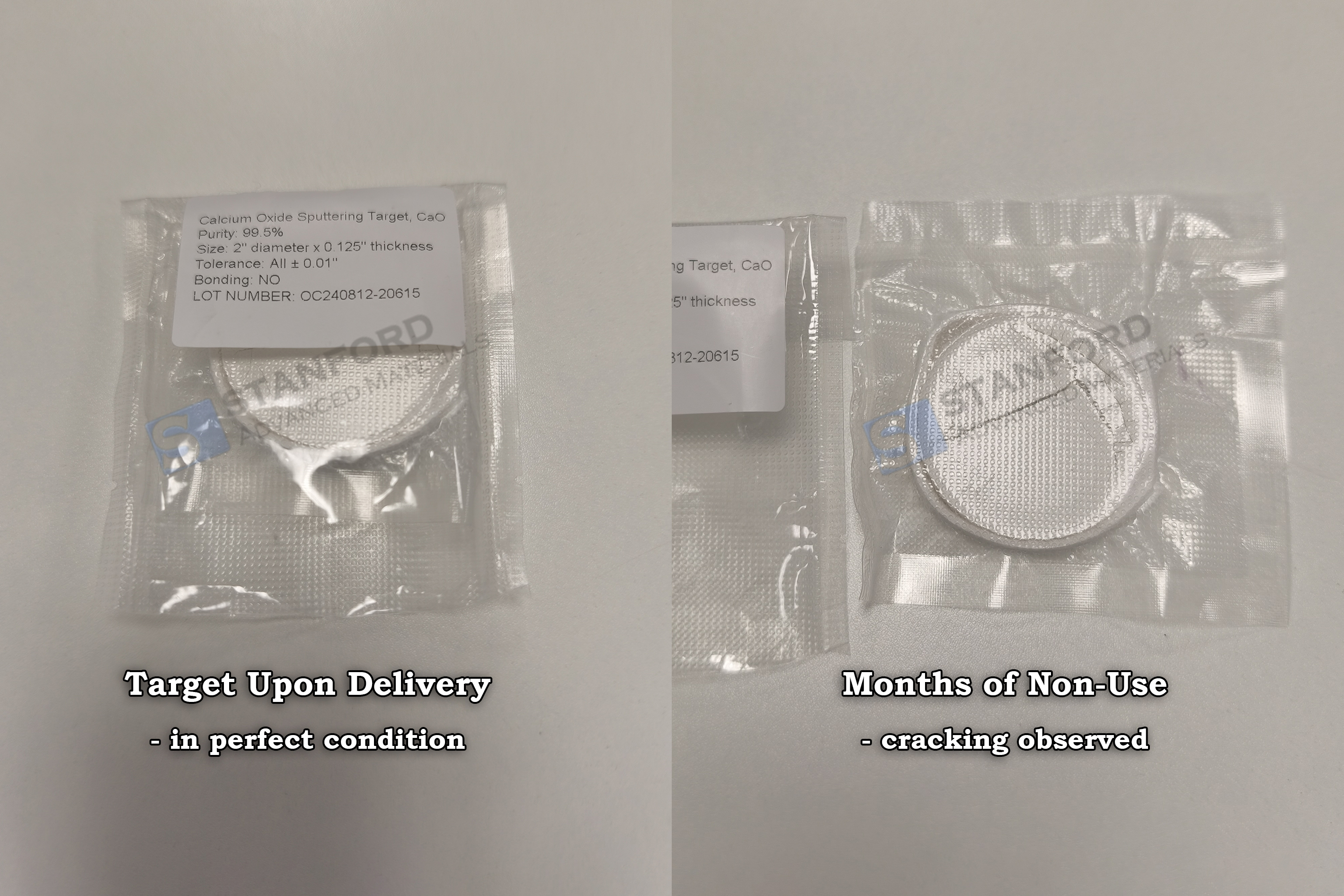

A recent example involved a Calcium Oxide (CaO) target that had been stored unopened for several months in its original packaging. By the time the customer was ready to use it, the target had developed visible cracks. Our investigation found no mishandling; rather, degradation occurred due to moisture sensitivity and delayed usage. To support the customer, we replaced the target free of charge and upgraded the packaging with a bonded backing plate.

This case is not isolated. It illustrates why storage conditions, packaging integrity, and material properties all matter—and why early preventive action is beneficial.

Want to know which materials are most sensitive? See the section below: "High-Risk Target Materials to Monitor."

General Storage Guidelines for All Sputtering Targets

Keep targets in a dry environment

Store targets in desiccator cabinets or humidity-controlled dry boxes. For moisture-sensitive targets, maintain relative humidity below 20%. Never store directly on open shelves.

Do not open vacuum packaging until ready to use the target

Breaking the vacuum seal exposes the material to moisture and oxygen. Once opened, degradation begins—even if the target appears acceptable.

Avoid temperature fluctuations

Avoid placing targets near vents, windows, or equipment that generates heat. Temperature changes can cause condensation, particularly inside sealed packages.

Use sensitive targets promptly

Once unpacked, use the target as soon as possible. For highly sensitive materials (e.g., CaO or NaCl), aim to use the target within 2–4 weeks of receipt.

Label storage and opening dates

Clearly mark or tag the date received and date opened. This assists all users in a laboratory setting to prioritise usage and mitigate risks associated with aging inventory.

High-Risk Target Materials to Monitor

Some sputtering targets require more than standard handling. These materials are prone to absorbing moisture, reacting with air, or changing structurally over time.

| Material | Risk Profile | Storage Recommendation |

|---|---|---|

| Calcium Oxide (CaO) | Highly hygroscopic; may crack easily | Vacuum-sealed; store in dry box; use within 2–4 weeks |

| Sodium Chloride (NaCl) | Absorbs water rapidly; may dissolve | Sealed storage; dry cabinet; avoid direct handling |

| Barium Fluoride (BaF₂) | Moisture-reactive surface | Dry storage; limit air exposure |

| Zirconium Oxide (ZrO₂) | Can degrade in humid environments | Store sealed; avoid extended storage |

| Magnesium Oxide (MgO) | Mildly hygroscopic; brittle | Store in dry box; inspect if unused for long |

| Hafnium Oxide (HfO₂) | Surface reactivity over time | Dry, sealed storage; minimal exposure |

| Nickel Oxide (NiO) | Prone to oxidation when exposed | Keep sealed; dry environment essential |

| Titanium suboxides | Reacts with moisture and light | UV-protected and moisture-isolated storage |

These materials are particularly vulnerable when exposed to air for extended periods. At Stanford Advanced Materials, we apply extra precautions to prevent such risks before they reach your location.

How SAM Ships and Protects Your Targets

Every sputtering target shipped by Stanford Advanced Materials (SAM) adheres to strict packaging protocols to ensure material safety during transit and storage:

-

Double-layer vacuum sealing for moisture-sensitive targets

-

Food-grade desiccant inside a sealed PP container

-

Foam cushioning for mechanical protection

-

Anti-moisture and "Fragile" warning labels on all packages

-

Lot tracking and QA inspection logged prior to shipment

Customers receiving SAM targets are advised to keep the packaging sealed until the material is ready for use. For long-term storage, we recommend transferring the unopened package into a dry cabinet immediately upon receipt.

Quick Reference Checklist of Target Storage

Store in <40% RH (ideally <20% for sensitive targets)

Keep vacuum seal intact until ready to use

Use moisture-sensitive materials within 2–4 weeks

Avoid temperature fluctuations in storage area

Label "Date Received" and "Date Opened"

Contact SAM for support if issues arise

This checklist can be printed and placed in laboratory storage areas as a daily reminder.

Conclusion

Preventing sputtering target damage relies on understanding the material, appropriate storage practices, and prompt action when needed.

At Stanford Advanced Materials, we extend our services beyond manufacturing. We assist our customers in protecting, handling, and maximising the value of every target they purchase. From packaging to post-sale support, our goal is to ensure your target performs as engineered—with no surprises or compromises.

If you require expert guidance on target storage, usage, or product selection, we are available to assist.

Get a quote today.

Also, see our sputtering target category here.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Rachel Monroe

Rachel Monroe