New Carbide Ceramics: The New Favorite Of Supersonic Aircraft Coatings

A supersonic transport (SST) is a vehicle that travels faster than the speed of sound. In general, vehicles with a Mach number below 1 are classified as subsonic, a Mach number above 1.2 is supersonic and a Mach number in excess of 5 is hypersonic. Supersonic aircraft have attracted the interest of many aircraft manufacturers because they travel faster and, in certain respects, more efficiently than conventional civil aircraft. However, developing economically feasible and reliable supersonic aircraft faces numerous challenges with current aeronautical technologies.

Current Research on Supersonic Aircraft

* Heat

It is known that the vehicle is exposed to high temperatures caused by aerodynamic heating, engine exhaust gases and solar radiation in outer space. When an aircraft flies for extended periods, its speed can reach up to three times the speed of sound. The high-temperature materials must demonstrate good heat resistance, creep resistance, thermal fatigue endurance, high oxidation resistance and resistance against thermal corrosion in both air and corrosive environments, as well as structural stability over long durations at high temperatures. The aviation environment often includes both high temperatures and high-speed airflow with particulate abrasion.

For example, the surface of an aircraft may experience temperatures between 2 000 and 3 000 °C when travelling at Mach 5, and the coating material can suffer degradation at these temperatures. The heat accumulation problem on the aircraft surface must be resolved to develop a supersonic aircraft. Recently, scientists have discovered a new carbon–ceramic coating that could contribute to the advancement of supersonic aircraft.

* Coating Material

For an aircraft to fly at supersonic speeds, its surface components must be protected from damage due to high air pressure and friction on structural elements. Currently, ultra‐high temperature ceramics (UHTC) are used for the external coating of the fuselage because these non-metallic materials remain stable at high temperatures. Although the conventional ceramic coatings are heat resistant, they can be easily damaged.

Zirconium diboride is frequently used for high-temperature coatings on aircraft because it is oxidation resistant at high temperatures, has a low density and incurs low costs. However, a significant disadvantage is that the boron in zirconium diboride promotes dissolution when boron atoms oxidise, which can result in severe consequences.

New Carbide Ceramics as an Enabler for Supersonic Aircraft

Studies have shown that when any material is exposed to sufficiently high temperatures, its molecular chains weaken and detach. This exposure can lead to ablation when particles impact at high speeds.

Carbide is currently one of the most heat-resistant materials and is represented by the general formula MxCy. Based on the properties of M, carbides are divided into metal carbides and non-metal carbides.

Carbide ceramics, such as silicon carbide, zirconium carbide, boron carbide and tungsten carbide, are commonly used as structural ceramics. These ceramic materials possess high melting points, considerable hardness and chemical stability. They are applied in various industrial sectors.

The newly developed carbide coating material can provide a coating with a strong and oxidation-resistant structure. It resists both ablation and oxidation in high-temperature environments. Introducing ceramic into carbon-fibre-reinforced carbon matrix composites has proved to be an effective method to improve impact resistance.

The new coating is a ternary alloy composed of zirconium, titanium, carbon and boron. It is incorporated into carbon composites by a process known as reactive melt infiltration. Although the coating exhibits properties similar to other carbide ceramics, it is less prone to ablation given its relatively low boron concentration, and the carbon matrix prevents the material from fracturing under thermal shock. Experimental results demonstrate that the carbide coating has improved ablation resistance at temperatures between 2 000 and 3 000 °C.

Applications of the New Ceramic Hardmetal Coating

Currently, the new coating is widely applied in the aeronautics and astronautics sector, given that spacecraft are exposed to substantial temperature fluctuations when traversing the atmosphere. Consequently, this material offers a safer alternative to conventional coatings.

Boeing CEO Dennis stated that the new supersonic passenger aircraft could enter service within the next decade and reduce travel times by up to 700%. Civil aircraft currently operate at subsonic speeds. Once civil supersonic aircraft are realised, global travel times will be significantly reduced, thereby facilitating communication among people.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

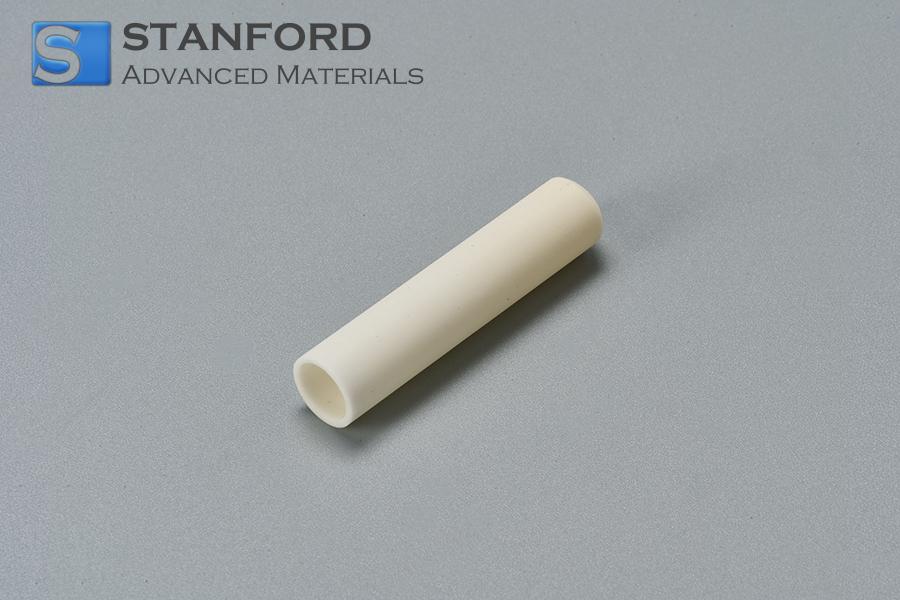

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento