What Are The Influencing Factors Of Wear Resistance Of Ceramics?

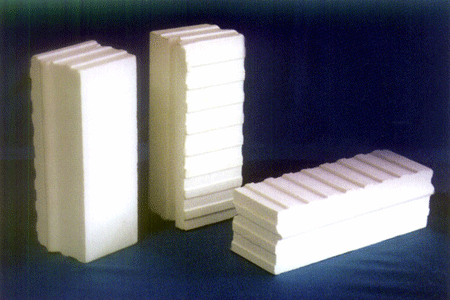

Wear‐resistant ceramic materials are widely used in sectors such as abrasive and polishing materials, wear‐resistant coatings, inner linings for pipes or devices, and structural components. Their wear‐resistant properties determine the safe service life of mechanical devices and components. Common wear‐resistant ceramic materials include Zirkoniumdioxid, Aluminiumoxid, cubic Bornitrid, Siliziumnitrid, Borcarbid and Siliziumcarbid.

To obtain ceramic materials with improved wear resistance, many researchers have examined the wear mechanisms and factors influencing wear. The wear behaviour of ceramics is affected by the material’s internal structure and by external factors such as load, temperature and atmosphere.

Effects of Mechanical Properties on the Wear Resistance of Ceramics

Early studies assumed that the hardness of ceramic materials was closely linked to wear resistance. Later investigations demonstrated that the relationship between hardness and wear is not definitive. For example, aluminium oxide ceramics exhibit higher hardness than TZP zirconia ceramics; however, their wear resistance is not necessarily higher than that of TZP ceramics.

Although hardness can reflect the bonding strength at grain boundaries to some extent, wear occurs when material chips off the surface. Consequently, hardness does not serve as a reliable predictor of wear. Some studies show that improvements in fracture toughness and hardness reduce the wear rate and increase wear resistance.

Effects of Microstructure on the Wear Resistance of Ceramics

The microstructure of a material influences its overall behaviour. Ceramics are sintered bodies composed of grains and intergranular phases. Their microstructure determines many of their macroscopic properties. Researchers have quantified that grain size, the composition of the grain boundary phase, stress distribution at the grain boundaries, porosity and other microstructural aspects affect wear resistance.

.jpg)

Grain Size

In industry, the mechanical properties of metals are improved by refining their grain size. This process, known as fine grain strengthening, increases the grain boundary area and creates a more complex grain boundary path. Consequently, the crack propagation path is lengthened and stress concentration is enhanced. Research has shown that grain refinement influences the wear resistance of ceramic materials.

Porosity

Porosity significantly impacts the properties of ceramic materials. Pores represent defects that cause stress concentration, accelerate crack propagation and reduce the bonding strength between grains. Under friction, pores may interconnect and form sites for crack initiation, thereby accelerating wear.

Grain Boundary Phases and Intergranular Impurities

Ceramics comprise grains, grain boundary phases and pores. During sintering, additives and impurities primarily accumulate at the grain boundaries as a second phase or glass phase. Their presence affects the bonding strength between grains. Under friction, cracks may develop at the grain boundaries. Reduced bonding strength leads to grain fracture, thereby resulting in severe wear.

In polycrystalline ceramics, additives typically occur at the grain boundaries in the form of a glass phase. Friction produces high temperatures that reduce the viscosity of the glass, thereby causing plastic deformation. If the stress at the adjacent grain boundary is insufficient, a crack forms, which leads to severe wear.

If an appropriate quantity of additives forms a second phase at the grain boundaries, the wear resistance of the material improves. For example, the addition of Zirkoniumdioxid to Aluminiumoxid produces alumina-stabilised zirconia, known as ZTA ceramics. The increase in critical stress induced by T-ZrO2 improves fracture toughness and strength. Zirkoniumdioxid and Aluminiumoxid inhibit grain growth and induce microcrystallisation, thereby further increasing wear resistance.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento