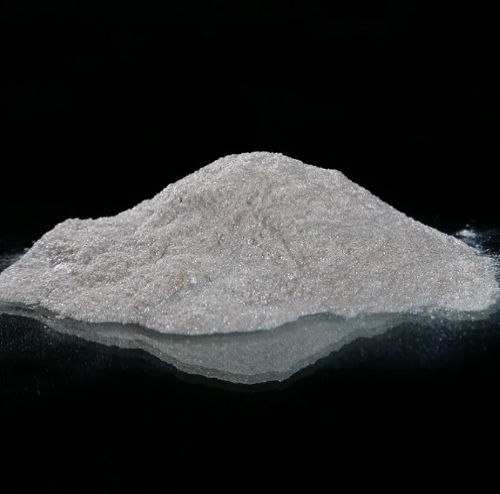

Diamond Powder For Optics: Precision Polishing And Finishing

Introduction

In the optics industry achieving ultra‐smooth and precise surfaces is crucial for lenses, mirrors and prisms. Diamond polishing powder is used because of its high hardness, fine particle size and uniform polishing performance. This document explains how diamond polishing powder is employed in optics and the reasons for its effectiveness.

Why Diamond Powder in Optics Is Required

Diamond polishing powder is used for its high hardness and controlled fine particles. It is the primary choice to polish optical components to the required standard.

- High Hardness: Diamond is the hardest known material. It allows the polishing of hard optical materials such as glass, sapphire and certain ceramics to achieve a near‐flawless finish.

- Precise Particle Sizes: Available in micron and submicron sizes, diamond powder permits controlled and consistent polishing. This precision is vital in optics, given that small surface imperfections can affect final performance.

- Flat, Scratch‐free Surfaces: Optical components require flat surfaces to ensure accurate light transmission and reflection. Diamond powder produces surfaces that reduce scattering and distortion in lenses and mirrors.

Applications of Diamond Powder in Optics

Diamond powder is used in the manufacture and finishing of optical components.

- Polishing of Lenses: In the final production phases, diamond powder is applied to remove surface irregularities and create a flat surface. This step is necessary for lenses used in cameras, telescopes, microscopes and other optical devices.

- Mirror Polishing: Precision mirrors require a flawless surface to ensure exact reflection. Diamond powder is applied to polish these mirrors, thereby reducing surface errors that could distort the reflected image.

- Polishing of Prisms: Prisms are used in applications such as spectrometry and imaging. The powder contributes to the required level of smoothness and clarity for accurate light refraction and transmission.

- Optical Fibre End Preparation: Diamond powder is used to polish the ends of optical fibres. A flat polished surface ensures efficient light transmission with minimal signal loss, which is important for high-speed data communication.

- Flat Optics and Waveguides: Flat optical components such as waveguides require ultra‐flat surfaces to guarantee effective light propagation and reflection. Diamond powder provides the fine finish needed to maintain these properties.

Types of Diamond Powder for Optics

Diamond powder is a practical abrasive used in polishing and finishing operations. The following types are employed in the optics sector:

- Monocrystalline Diamond Powder: This type consists of single crystals that yield sharp and precise cutting edges. It is generally used in the initial polishing stages when more material is removed to produce a flat surface.

- Polycrystalline Diamond Powder: Comprising many small crystals, this type provides a less aggressive cut. It is appropriate for later polishing stages to achieve a scratch‐free surface.

Frequent Applications of Diamond Polishing Powder

Diamond powder is used in several industries including metals, gemstones, ceramics and precision optics.

- Polishing of Metals: Diamond powder is used to polish hard metals such as tungsten carbide, stainless steel and tool steel in order to achieve a high‐gloss finish required for many industrial components.

- Polishing of Gemstones and Jewellery: It is used in the polishing of gemstones, particularly diamonds, to achieve a finish that highlights clarity.

- Glass and Optical Components: In the optics industry, diamond powder is applied in the polishing of lenses, mirrors and prisms to create surfaces that can transmit light precisely.

- Polishing of Ceramics: Diamond powder is used to polish ceramics, especially in electronic applications, where a flat surface contributes to improved performance and durability.

- Automotive and Aerospace Components: The use of diamond powder in the polishing of engine components or turbine blades helps to reduce friction and wear, thereby extending the life of these parts.

How to Use Diamond Polishing Powder

To use diamond polishing powder effectively, follow these steps:

- Mixing with a Carrier: Diamond powder is typically mixed with a carrier liquid such as water or oil to form a slurry. This slurry ensures an even application and consistent movement across the surface.

- Application: Apply the diamond slurry to a polishing cloth, pad or disc. The choice of applicator depends on the material and the required finish.

- Polishing Process: Move the tool with the diamond coating in a uniform, controlled manner across the surface. Continue until the desired flatness and shine is achieved.

- Use of Different Grits: Start with a coarser grade of diamond powder to remove surface imperfections. Thereafter, switch to finer grades to achieve the required level of smoothness and clarity.

Stanford Advanced Materials (SAM) supplies nano‐diamond powder in various sizes suitable for enhancing product performance in a range of applications. The ultra‐fine particles provide high hardness and are ideal for use in abrasives, polishing pastes and cutting tools where precision and an excellent surface finish are required. Custom adjustments are available. For further information, please visit our homepage.

Conclusion

The high hardness of diamond powder, its controlled fine particle size and its capacity to produce flat, defect‐free surfaces make it an established standard for polishing optical components. Its application in lenses, mirrors, prisms and optical fibre ends provides the precision necessary in the optics industry and supports the manufacture of advanced devices and high‐performance optical systems.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento