Case Study: Elevating Paper Applications With Micro Boron Nitride

Introduction

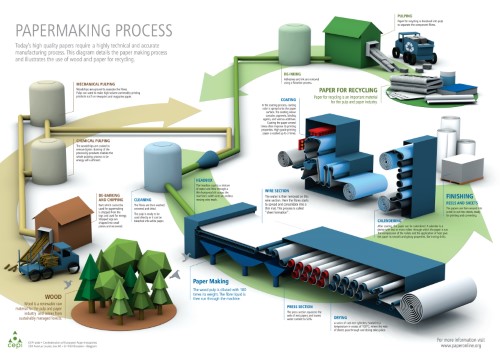

The paper and pulp industry is undergoing significant change, driven by the pursuit of higher‐grade products and sustainable practices. Micro-Boron Nitride (BN), which is known for its high thermal conductivity, lubricating properties and electrical insulation, may play an important role. This article examines its integration into the paper and pulp manufacturing process and details its quantifiable impacts.

[1]

[1]

Figure 1. Paper Production

What is Micro-Boron Nitride?

Micro-BN consists of hexagonal boron nitride nanoparticles. Its high thermal conductivity ensures efficient heat dissipation, while its lubricating properties reduce friction and wear. Its electrical insulation reduces static electricity issues in the production process.

Figure 2. Micro-Boron Nitride

How is Micro-Boron Nitride utilised in the paper and pulp industry?

The properties of Micro-BN have led to its adoption in the paper and pulp industry. The following sections detail its application:

Improved Thermal Management: The high thermal conductivity of Micro-BN facilitates effective heat dissipation during paper and pulp processing. Consequently, manufacturers can prevent thermal damage and maintain structural integrity during high-temperature operations.

Enhanced Lubrication: The inherent lubrication properties qualify it as an appropriate additive in the production of pulp, paper and cardboard. The addition of Micro-Boron Nitride extends product lifespan and reduces maintenance requirements.

Flame Retardancy: The flame-retardant characteristics of Micro-BN contribute to increased safety in paper and pulp products. This effect reduces the risk of ignition and improves fire safety.

Enhanced Mechanical Properties: Micro-BN can improve tensile strength, tear resistance and dimensional stability.

Barrier Coatings: When applied as barrier coatings, Micro-BN restricts the ingress of liquids and gases. Consequently, the durability and quality of packaged goods are maintained.

Environmentally Acceptable Solutions: The non-toxic and environmentally friendly attributes of Micro-BN comply with sustainable practices in the paper and pulp industry.

Case Study: Micro-Boron Nitride in the Paper and Pulp Industry

The Challenge

In an effort to improve paper quality and performance, a client initiated the integration of Micro-Boron Nitride in paper applications. The primary aim was to define critical specifications that would maximise the product’s effectiveness. SAM recognised the importance of particle size and purity and assessed these factors carefully to ensure optimal incorporation of Micro-Boron Nitride.

The Solution

Particle Size: A consistent particle size is essential for incorporating BN powder in paper. Fine powders achieve optimal dispersion and compatibility with paper fibres. SAM recommends selecting BN powders in the range of 1–10 microns, which facilitates integration and improves paper properties.

Purity: Purity is a key quality indicator in selecting BN powder. To maintain the integrity of paper products, highly pure BN powders are advised. SAM recommends BN powders with a purity exceeding 99%, thereby minimising any adverse effect on paper characteristics.

The Results

The controlled addition of BN powder improves paper quality, increases processing efficiency and supports environmental sustainability.

Conclusion

The integration of Micro-Boron Nitride (BN) in the paper and pulp industry introduces a new phase of modern processing methods and improved material characteristics. By utilising thermal conductivity, lubrication, flame retardancy and mechanical enhancement, manufacturers can produce paper and pulp products that meet the stringent industry requirements and contribute to safety, efficiency and sustainability. Stanford Advanced Materials (SAM) is a supplier of high-quality nanomaterials. Please contact us if you are interested.

Reference:

[1] CEPI. About Pulp and Paper. CEPI. https://www.cepi.org/about-cepi/history-of-pulp-paper/

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento