Case Study: Enhancing Dental Applications With Spherical TC4 Titanium-Based Powder

Introduction

Dentistry is undergoing a technological transition driven by new materials such as Spherical TC4 Titanium-Based Powder (Ti-6Al-4V). This titanium alloy offers a combination of biocompatibility, mechanical integrity and corrosion resistance that supports enhanced dental outcomes.

This discussion details specific applications that illustrate the use of Ti-6Al-4V in dentistry. We present measured data regarding its properties and practical applications.

[1]

[1]

Figure 1. Dentistry

Understanding Spherical TC4 Titanium Powder

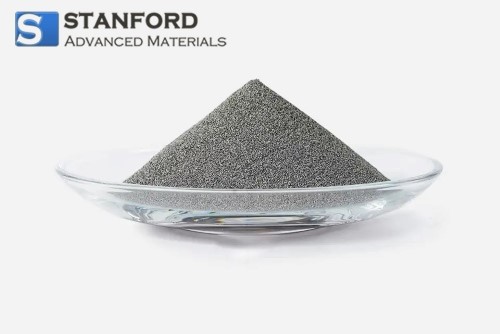

Spherical TC4 titanium-based powder is a widely used alloy. It consists of 90% titanium, 6% aluminium and 4% vanadium. The combination of these elements provides biocompatibility, corrosion resistance, low weight and reliable mechanical properties. Consequently, Ti-6Al-4V is frequently employed in medical and dental applications.

Figure 2. Spherical TC4 Titanium-Based Powder

Applications in Dental Practice

Ti-6Al-4V powder is used in dentistry for the precise manufacture of components and implants. The material is processed to meet specific engineering criteria. The following outlines its uses:

Dental Implants: Ti-6Al-4V is used to produce dental implants. Its biocompatibility assists in bone integration and reduces the risk of rejection or complications.

Crowns and Bridges: Its low weight and appropriate strength-to-weight ratio make it suitable for crowns and bridges that serve as a foundation for prosthetic teeth.

Orthodontic Appliances: The powder is used in the manufacture of devices such as braces, wires and brackets. These components satisfy strict mechanical requirements for applying controlled forces to teeth.

Partial Dentures: Given its light weight and biocompatibility, spherical TC4 powder is used to produce the framework for removable partial dentures.

Other Uses: Titanium-based materials are also used in the production of dental surgical instruments and both temporary and permanent prosthetic components, including abutments for dental implants.

Case Study: Spherical TC4 Titanium Powder for Dentistry

-- The Challenge

A dental manufacturer required improved quality and performance for dental implants, orthodontic appliances, bone repair materials and support frameworks. The objective was to utilise a spherical titanium alloy powder that met strict criteria for particle size, surface quality and sphericity. This requirement was set to optimise product performance and patient outcomes.

-- The Solution

Stanford Advanced Materials (SAM) provided a customised solution that met the client’s specifications:

1. Particle Size Adjustment:

For dental implants, orthodontic devices and load-bearing components, SAM recommended Spherical TC4 powder with particle sizes ranging from 20 to 100 microns. This range ensured measurable improvements in mechanical performance. For dental bone repair materials and support frameworks, a range of 1 to 20 microns was proposed. The reduction in particle size contributed to improved material integration within the oral cavity.

2. Surface Quality Assurance:

The Ti-6Al-4V powder was processed to achieve a smooth surface free from oxide layers and contaminants. This quality control process ensured safety and consistency.

3. High Sphericity:

The spherical form of the powder enables uniform mixing and facilitates machine processability during manufacturing.

-- The Results

The SAM solution for spherical TC4 powder delivered measurable improvements in product quality. Mechanical performance and production processes were evaluated through standardised tests. Consequently, dental treatments achieved improved outcomes, providing tangible benefits to patients and offering a competitive advantage within the dental industry.

Conclusion

Ti-6Al-4V and other titanium alloys contribute to modern dentistry by providing a stable basis for dental crowns, bridges and dentures. Given the ongoing evolution in dental techniques, the use of titanium-based materials represents progress in material science. Stanford Advanced Materials (SAM) has extensive experience in manufacturing high quality spherical TC4 powder (Ti-6Al-4V). For further information, please visit our homepage.

Reference:

[1] Encyclopedia Britannica (2023). Dentistry [Photograph]. Encyclopedia Britannica. https://www.britannica.com/science/dentistry#/media/1/158069/108226

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento