Case Study: Enhancing Electronics With The Luminescent Brilliance Of Europium Oxide

Introduction

In the complex field of electronics, some materials are utilised due to their technical properties. Europium Oxide (Eu2O3) is one such compound. It exhibits distinctive optical and electronic properties and occupies a specific role in the electronics industry.

This article examines the applications of Europium Oxide and its influence on the development of electronic devices. The analysis focuses on its use in electronics.

Figure 1. Electronic Components [1]

What is Europium Oxide?

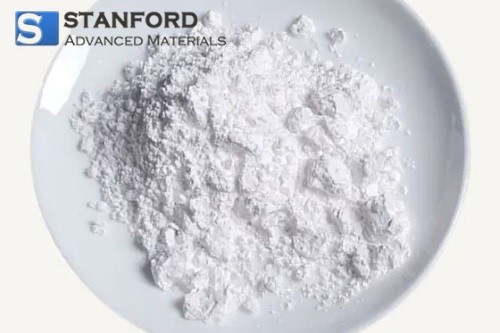

Europium Oxide (Eu2O3) is the oxide of the rare‐earth element Europium (Eu). This white or pale yellow solid has a high melting point, is insoluble in water and remains stable at standard temperature and pressure. Its principal characteristic is luminescence, which makes it essential for applications such as phosphors in displays and lighting.

Figure 2. Europium Oxide (Eu2O3)

How is Europium Oxide Used in Electronics?

Due to these properties, Europium Oxide is used in various applications within electronics.

1. Phosphors and Luminescence: This oxide is used in the production of phosphors for cathode‐ray tubes (CRT), plasma screens and fluorescent lamps.

2. Laser Technology: Eu2O3 is utilised in laser technology, particularly in solid‐state lasers and fibre lasers. These lasers are used in communication systems, medical devices and research laboratories.

3. Semiconductor Fabrication: In the semiconductor industry, Eu2O3 is employed as a dopant to modify the electrical and optical properties of semiconductors.

4. Optical Coatings: Eu2O3 is incorporated into optical thin film coatings that improve reflective, transmissive or absorptive characteristics at specific wavelengths. These coatings are used in optical instruments such as lenses, mirrors and filters, which are found in lasers, cameras and spectrometers.

Case Study: Europium Oxide (Eu2O3) in Electronics

--The Challenge

A company required Europium Oxide powder for the manufacture of LED and LCD backlight modules. It specified powder characteristics, including particle size, stability, purity and luminescence performance, to meet the required performance and optical quality of the final products.

--The Solution

In response to these technical requirements, Stanford Advanced Materials (SAM) provided a customised proposal.

Particle Size for Colour Uniformity: A particle size in the range of 1–10 microns is recommended to achieve uniform dispersion and consistent colour across the backlight module.

Chemical and Thermal Stability: The specified Europium Oxide powder must exhibit chemical and thermal stability, thereby reducing the likelihood of structural or performance changes.

High Purity for Manufacturing Integrity: SAM selected a high‐purity powder to limit the presence of contaminants that may affect luminescence and overall material performance.

Customised Luminescence: Customer requirements regarding specific luminescent effects, such as colour temperature and saturation, were considered in the development of LED and LCD backlight modules.

--Results

By addressing these parameters, manufacturers provided backlight modules that meet specified requirements for colour uniformity, stability and luminous output.

Conclusion

Europium Oxide is applied in various electronic systems, including display technologies, lasers, semiconductors and radiation detection. Its optical and electronic properties contribute to the performance of a range of electronic devices and components.

Stanford Advanced Materials (SAM) supplies high‐purity Europium Oxide and a variety of rare‐earth chemicals. Customised products are available. Please submit an enquiry if required.

Reference:

[1] Electronics. (09/08/2023). In Wikipedia. https://en.wikipedia.org/wiki/Electronics

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento