Key Types Of Wire Bonding Materials

Introduction

In semiconductor manufacturing, wire bonding establishes the electrical connections between chips and external circuits. The selection of the wire material is crucial, as it influences bonding quality, electrical performance and the long-term reliability of semiconductor devices. This article details the most frequently used wire materials for wire bonding, including gold wire, gold-plated wire, copper wire and copper alloy wire.

What is Wire Bonding?

Wire bonding refers to the process of creating electrical and mechanical connections between semiconductor components (e.g. integrated circuits and transistors) and external circuits. The main purpose of wire bonding is to ensure a stable connection between the chip and its package leads or substrate, thereby allowing correct signal transmission and device functionality.

1. Common Wire Bonding Methods:

Wire bonding involves forming electrical connections between a microchip and its package or between two chips. The primary categories of wire bonding are:

- Ball Bonding:

In this method, heat is applied to form a ball at the end of a wire, which is then pressed onto the bond pad with force. This technique is most widely used for gold or copper wires. Ball bonding is routinely employed in high-speed applications.

- Wedge Bonding:

In wedge bonding, a wedge-shaped bond is produced by applying ultrasonic energy to press the wire onto the surface at an angle. Wedge bonding is frequently chosen for aluminium wires and is suitable for fine-pitch and small devices, particularly when space is limited.

- Compliant Bonding:

This technique utilises a compliant or soft layer to absorb stress and maintain the integrity of the connection, especially when bonding dissimilar materials. Although used less commonly, it remains effective for applications in which differences in thermal expansion can cause bond failure.

Each category is applied according to the materials used, the operating conditions and the required performance.

2. Key Characteristics of Wire Bonding:

Wire bonding affects the performance, reliability and lifecycle of electronic products in terms of the following aspects:

- Electrical connectivity: Ensures that electrical signals flow correctly between the semiconductor chip and the circuit board.

- Mechanical stability: Provides physical support for the chip and helps it withstand vibrations, temperature variations and other environmental influences.

- Thermal management: Contributes to dissipating heat generated during operation via the bonds and connections, thereby maintaining stable device performance.

Main Types of Wire Bond Materials

1. Gold Wire

Gold wire is commonly used for wire bonding due to its high electrical conductivity and notable resistance to corrosion. As it bonds readily, it is a reliable choice for applications requiring high reliability – for instance, in aerospace and modern electronics, where precision and durability are critical.

- Advantages: Gold wire provides high electrical conductivity and outstanding corrosion resistance. It performs reliably in both thermal and ultrasonic bonding processes.

- Applications: It is used in integrated circuits (ICs), light-emitting diodes (LEDs) and solar cells.

Gold wire is typically selected for environments where longevity and the ability to resist harsh conditions are required. The high cost of gold has, consequently, driven the search for more cost-efficient alternatives.

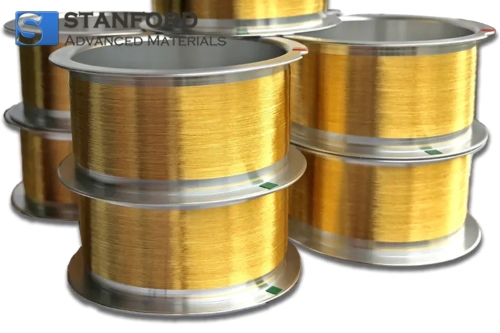

2. Gold-Plated Wire

Gold-plated wire is a cost-effective alternative to solid gold wire. Typically, it consists of a copper or silver core coated with a thin layer of gold. This configuration retains many of the beneficial properties of gold, such as corrosion resistance, while preserving the strength and lower cost of the core material.

- Advantages: Gold-plated wire is less expensive than solid gold wire while maintaining good electrical conductivity and corrosion resistance.

- Applications: It is widely used in consumer electronics, automotive electronics and other circuits requiring moderate reliability.

Sectors that require moderate reliability and are cost-sensitive frequently select gold-plated wire because it offers a balanced performance-to-cost ratio.

3. Copper Wire

Copper wire is increasingly used as an alternative to gold wire in wire bonding due to its high electrical and thermal conductivity at considerably lower cost. It is preferred in high-volume applications where cost efficiency is paramount.

- Advantages: Copper wire provides high electrical and thermal conductivity and is substantially less expensive than gold. It is particularly suited for high-power devices.

- Applications: Copper wire is used for power transistors, chip packages and power modules.

The high thermal conductivity of copper wire assists in effective heat dissipation, thereby improving the reliability of devices under significant operational loads.

4. Copper Alloy Wire

Copper alloy wire is composed of copper with minor additions of other metals to enhance mechanical strength and wear resistance. This type of wire is employed in applications where high durability is necessary without compromising electrical performance.

- Advantages: Copper alloy wire is stronger than pure copper, offers adequate wear resistance and provides sufficient conductivity for high-frequency applications.

- Applications: It is implemented in high-frequency components, power electronics and complex semiconductor packages.

Copper alloy wires are chosen for semiconductor devices that encounter significant mechanical stress or frequent electrical switching, thereby ensuring long-term device reliability.

Conclusion

The choice of wire bonding material determines the performance, lifespan and cost efficiency of the final semiconductor product. Gold wire remains the preferred material for applications that demand high reliability. In contrast, copper and copper alloy wires offer high performance at lower costs, particularly in high-power or high-frequency devices. Gold-plated wires provide a balanced option for applications with moderate reliability requirements.

Stanford Advanced Materials (SAM) offers a wide range of high-quality wire products that are known for their purity, precision and reliability. Whether using precious metals, non-ferrous metals or high-melting-point alloys, our wires deliver the strength, flexibility and durability required in scientific applications. For further information, please visit our homepage.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento