Case Study: Powering The Future Of Solar Energy With Cadmium Telluride

Introduction

Cadmium telluride (CdTe) has established itself as a principal material in solar energy applications. Recognised for its photovoltaic performance characteristics, CdTe converts sunlight into electricity with high conversion rates. This process offers a method for generating renewable energy at reduced manufacturing costs and with scalable output. In this article, the role of CdTe in solar technology is described, and its advantages, limitations and significance for the renewable energy sector are discussed.

Figure 1. Solar Panels

Understanding Cadmium Telluride

Cadmium telluride (CdTe) is a compound semiconductor material that has been extensively studied for its role in photovoltaic applications. It is employed in the manufacturing of thin-film solar cells that convert sunlight into electricity. This thin-film structure not only enables efficient light absorption but also reduces material consumption compared with conventional silicon solar cells.

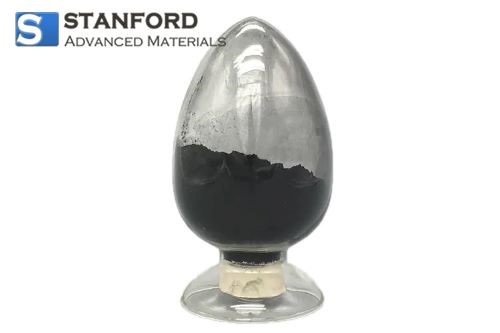

Figure 2. Cadmium Telluride Powder

Advantages of Cadmium Telluride Solar Cells

CdTe solar cells have gained popularity owing to their conversion efficiency, cost efficiency and suitability for large-scale commercial applications. The main features are as follows:

Conversion Efficiency: CdTe cells achieve conversion rates that are competitive with other thin-film technologies and some silicon-based solar cells.

Cost Efficiency: The production process for CdTe cells requires less material and fewer processing steps than conventional silicon cells. Consequently, manufacturing costs are reduced, thereby lowering overall system expenditure.

Challenges: Although these solar cells offer defined benefits, they also present challenges. The toxicity of cadmium necessitates careful handling and disposal, and there are concerns that cadmium may leach in cases of module damage or gradual degradation.

Case Study: Cadmium Telluride for Solar Energy

--The Challenge

A client required high-quality cadmium telluride materials for solar energy technology and subsequently contacted Stanford Advanced Materials (SAM). SAM, using its established expertise in materials science and renewable energy applications, provided recommendations to optimise the performance of CdTe in solar energy systems.

-The Solution

The following specifications for cadmium telluride products are recommended:

Cell Size: The choice of cell size is important for striking a balance between conversion efficiency, manufacturing costs and scalability. Commercial CdTe solar cell specifications typically include 3‑inch, 4‑inch and 6‑inch sizes. The 4‑inch CdTe cell offers a higher conversion efficiency and lower manufacturing cost, which makes it suitable for mass production and commercial use.

Purity: Purity is a critical factor affecting the conversion efficiency of solar cells. A higher purity of the CdTe material facilitates improved charge-carrier transport and limits defects that may impair performance. A purity level of 99.99% or higher is recommended to achieve optimal conversion efficiency.

Crystallographic Structure: The quality of the crystal structure in CdTe is directly linked to both the performance and the operational lifespan of the solar cell. A well-defined crystal structure minimises defects and improves charge-carrier transport.

--Results

These considerations highlight the importance of material quality in the production of CdTe solar cells. Consequently, customers can obtain CdTe material that is engineered to deliver enhanced conversion efficiency, operational stability and extended performance.

Conclusion

CdTe solar cells, with their high light absorption, elevated conversion efficiency and an optimised bandgap, offer a practical solution for large‑scale solar energy generation at reduced manufacturing costs. Stanford Advanced Materials (SAM) is a reliable source for a range of cadmium telluride compounds. The company also provides customised products. Please contact SAM with your enquiries.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento