Building Blocks Of Progress: Tantalum Oxide Powder And Its Influence In Materials Science

Introduction

In the field of materials science, progress depends on the identification of new components with specific properties. Tantalum oxide powder, despite its unassuming appearance, plays an important role across various sectors. This article reviews its function and impact within materials science.

[1]

[1]

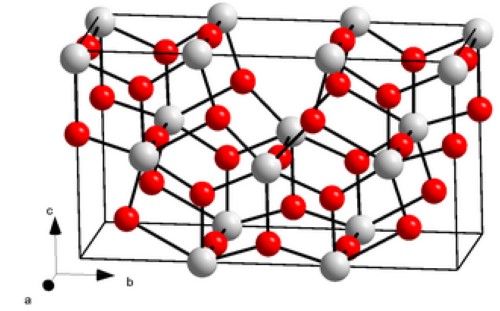

Figure 1. Tantalum Oxide

Tantalum Oxide: A Fundamental Component

Before considering its applications, the fundamental characteristics of tantalum oxide must be understood. Tantalum, a rare transition metal, reacts with oxygen to form tantalum oxide (Ta₂O₅). This compound exhibits a set of defined properties.

l High dielectric constant: Tantalum oxide has a high dielectric constant, enabling capacitors to store a greater amount of charge per unit volume. Consequently, this allows the minimisation of electronic components.

l Chemical stability: The oxide exhibits chemical stability and resists corrosion and decomposition even in aggressive chemical environments. This ensures a consistent performance in its applications.

l Thermal resistance: Its thermal stability qualifies it for high-temperature applications. It is used as a protective coating for components in aerospace, automotive, and industrial machinery.

l Low leakage current: Capacitors that incorporate tantalum oxide demonstrate low leakage currents, thereby enhancing charge retention. This improvement contributes to more efficient energy consumption and longer battery life.

Applications in Materials Science

The defined properties of tantalum oxide are applied in several materials science processes:

1. Modern material synthesis: Researchers utilise tantalum oxide as a precursor in the synthesis of advanced materials, including thin films and nanoparticles. These materials are employed in electronic devices, high-temperature coatings and composite structures.

2. Nanotechnology: The catalytic properties of tantalum are applied in nanotechnology to produce nanomaterials that contain tantalum. This is used in the development of electronic components, energy storage systems and various sensor technologies.

Further reading: What is tantalum oxide used for?

Conclusion

In summary, tantalum oxide powder is a standard component within the field of materials science. Its specific properties facilitate developments in electronic devices, coatings and advanced materials, contributing to the manufacture of devices that are smaller, more energy efficient and reliable.

Discover high quality Tantalum Oxide Powder at Stanford Advanced Materials (SAM), a reliable supplier known for strict quality standards. A range of grades and custom solutions are available. Please send an enquiry if you are interested.

Reference:

[1] Tantalum pentoxide. (18/08/2023). In Wikipedia. https://en.wikipedia.org/wiki/Tantalum_pentoxide

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento