The Contact Material Range Of Refractory Metals

Introduction

Refractory metals are recognised for their high melting point, strength at elevated temperatures and notable resistance to wear and corrosion. These properties permit their use in various industrial applications, ranging from aerospace engineering to chemical processing plants.

Selecting compatible contact materials is essential to maintain the performance and service life of refractory metals in different environments. This article discusses the compatible and reactive materials for each refractory metal and provides technical insight for engineers and designers.

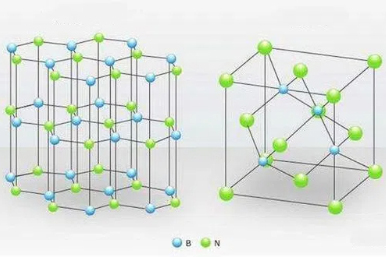

Understanding Refractory Metals

Refractory metals are a class of metals that withstand high temperatures and considerable wear. The term is applied primarily to five elements: tungsten (W), molybdenum (Mo), tantalum (Ta), niobium (Nb) and rhenium (Re). These elements share a high melting point, which is substantially above that of most other metals.

Refractory metals exhibit several important characteristics that qualify them for demanding applications:

1. High melting points: For instance, tungsten melts at 3 422 °C, which is the highest value recorded among metals. Consequently, refractory metals are used in furnace components and rocket engines.

2. High density: Tungsten has a density of up to 19 25 g/cm³, a figure that indicates its suitability for applications requiring heavy materials in a compact form, such as radiation shielding and counterweights.

3. Hardness and strength: These metals maintain their structural properties and resist deformation under mechanical load even at elevated temperatures.

4. Corrosion resistance: Metals like tantalum and niobium demonstrate excellent resistance to corrosion, including exposure to acids, a factor that is important in chemical processing.

Read further: Everything you need to know about refractory metals

Contact Material Range for Refractory Metals

Refractory metals are therefore valuable for applications that require operation under extreme conditions which other materials cannot tolerate. Their deployment is subject to certain limitations that can affect performance. The challenges concerning contact materials must be managed with care.

The contact material field refers to the selection of materials used in direct contact with high-melting metals. These materials are chosen because they can withstand similar extreme conditions without corroding, decomposing or otherwise adversely interacting with the refractory metals. To optimise design and ensure durability, these materials are classified into compatible and reactive groups. Compatible materials maintain their structural integrity and performance when used with refractory metals, such as specific ceramics and metals that do not react at high temperatures. Conversely, reactive materials can lead to corrosion or chemical reactions that may result in component failure. This classification assists engineers in making informed decisions to enhance the reliability and longevity of refractory metal applications. The following sections list typical refractory metals along with their compatible and reactive materials.

1. Tungsten (W)

Tungsten is used for its strength and temperature resistance, making it appropriate for applications in aerospace engineering and electronics.

- Compatible materials: Tungsten is typically combined with steel, nickel, ceramics and glass, serving applications that require high thermal and electrical conductivity.

- Reactive materials: It is less suitable for use with materials that promote oxidation or increase brittleness, such as certain copper alloys at elevated temperatures, which may impair structural integrity.

2. Molybdenum (Mo)

Molybdenum is recognised for its versatility and is used as a core material in high-temperature furnaces and electronic applications.

- Compatible materials: Molybdenum is generally paired with ceramics and glass to utilise its capacity to withstand significant thermal variation and its high melting point.

- Reactive materials: Use with oxidising agents above 400 °C is not recommended, given that rapid oxidation can diminish its effectiveness and durability.

3. Tantalum (Ta)

Tantalum’s marked corrosion resistance renders it useful in the chemical processing industry and in the manufacture of medical devices.

- Compatible materials: This metal is suitable for use with a wide range of chemical substances, including acids, bases and noble metals.

- Reactive materials: Tantalum is reactive when exposed to alkaline solutions and molten metals, and it may suffer hydrogen embrittlement at elevated temperatures.

4. Niobium (Nb)

Niobium is often employed in superalloys and applications that require excellent corrosion resistance.

- Compatible materials: It is well suited for use with ceramics and in environments that demand chemical resistance.

- Reactive materials: Exposure to oxygen and halogens at high temperatures may impede its performance, so regulated atmospheres are required.

5. Rhenium (Re)

Rhenium is employed as an alloying element to improve the performance of other refractory metals, particularly in high-temperature conditions.

- Compatible materials: Rhenium is frequently alloyed with tungsten and molybdenum, and its compatibility with platinum-group metals is used in electrical contact applications.

- Reactive materials: Although Rhenium is relatively inert, caution is advised when it is used in oxidising atmospheres at elevated temperatures.

Conclusion

Selecting appropriate contact materials for refractory metals (see Table 1) is critical to ensure the stability and function of these metals in their respective applications. Engineers must consider thermal compatibility, chemical reactivity and mechanical properties when incorporating refractory metals into their designs. This understanding assists in making informed decisions that enhance performance metrics and extend material service life in complex industrial settings. Further details are available at Stanford Advanced Materials (SAM).

Table 1. Contact Material Range of Refractory Metals

|

Metal |

Compatible Materials |

Reactive Materials |

Applications |

|

Steel, Nickel, Ceramics, Glass |

Copper alloys (at elevated temperatures) |

Aerospace, Electronics |

|

|

Ceramics, Glass |

Oxidising agents (above 400 °C) |

High-temperature furnaces, Electronics |

|

|

Acids, Bases, Noble metals |

Alkaline solutions, Molten metals, Hydrogen embrittlement at elevated temperatures |

Chemical processing, Medical devices |

|

|

Niobium (Nb) |

Ceramics, Environments requiring chemical resistance |

Oxygen, Halogens (at elevated temperatures) |

Superalloys, Chemical resistance |

|

Rhenium (Re) |

Tungsten, Molybdenum, Platinum-group metals |

Oxidising atmospheres (at elevated temperatures) |

High-temperature alloys, Electrical contacts |

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento