Tungsten Carbide Cobalt: An Overview

Introduction

Wolframkarbid-Kobalt, often termed sintered carbide or simply carbide, is a composite material. It is composed of tungsten carbide (WC) and cobalt (Co). WC provides hardness and wear resistance, while cobalt acts as a binder that holds the WC particles together. The material is used in various industrial processes.

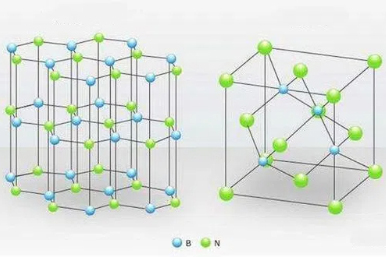

Composition and Properties

Tungsten carbide-cobalt typically comprises between 70–97 % tungsten carbide; the remainder is cobalt. The ratio depends on the specific property requirements. A higher WC content increases measured hardness and wear resistance, whereas a higher cobalt proportion improves impact resistance.

The primary properties of tungsten carbide-cobalt include:

- Hardness: The material achieves high hardness as measured by standard tests. It is used in machining processes that require maintained edge definition.

- Wear resistance: Owing to its dense structure, tungsten carbide-cobalt exhibits resistance to wear under high operational loads.

- Toughness: The inclusion of cobalt provides a quantifiable degree of toughness, which reduces the risk of sudden fracture under impact.

- Heat resistance: The material performs at elevated temperatures without a significant loss of hardness.

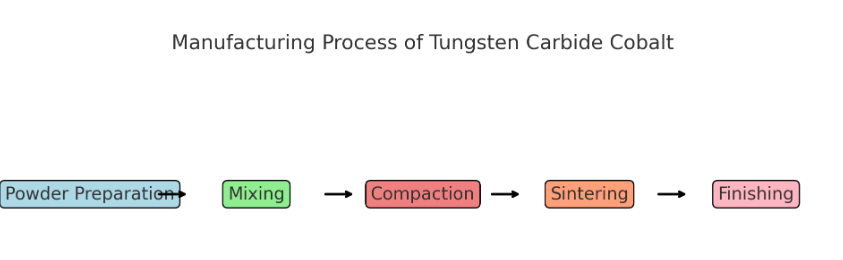

Manufacturing Process

The production of tungsten carbide-cobalt involves several steps:

- Powder preparation: Precisely measure tungsten carbide powder and cobalt powder. Additional additives can be introduced to adjust specific properties.

- Mixing: Blend the powders thoroughly. This step ensures an even distribution of the cobalt binder among the tungsten carbide particles.

- Compaction: Compress the blended powders under high pressure into the required shape. A die is frequently used to form the final product.

- Sintering: Heat the compacted material to a temperature just below cobalt’s melting point. During this step, cobalt melts and bonds the WC particles together, thereby forming a dense structure.

- Finishing: Subject the sintered material to processes such as grinding, cutting or coating to meet specific application requirements.

Applications

Tungsten carbide-cobalt is employed in several applications because of its quantifiable properties:

- Cutting tools: The material is used to fabricate drill bits, milling cutters and saw blades. It retains its cutting edge and resists wear when processing hard materials such as steel and alloys.

- Mining and construction: It is used in the production of drilling devices, excavation tools and rock cutting equipment. This use is driven by its high hardness and toughness.

- Wear parts: In industries where machinery is exposed to continuous wear, tungsten carbide-cobalt components are employed to extend equipment service life. Examples include nozzles, valve seats and bearings.

- Aerospace and defence: Given that the material performs under high temperatures and pressures, it is utilised in the manufacture of aircraft components and armour-piercing munitions.

Advantages and Challenges

- High hardness and wear resistance: The material’s measured hardness and resistance to wear allow its use in applications that encounter significant abrasive forces.

- Adaptability: Adjusting the tungsten carbide to cobalt ratio tailors the material to specific operational requirements.

- Extended operating life: Components manufactured from tungsten carbide-cobalt generally exhibit a longer service life compared to those made from other materials.

Although tungsten carbide-cobalt provides measurable advantages, certain challenges must be considered.

- Brittleness: Despite its toughness, the material may become brittle when used in thin sections or under high stress.

- Costs: The production process incurs relatively high costs, which can limit its application in certain contexts.

- Health and environmental considerations: The use of cobalt requires careful handling to minimise health risks, and the extraction of tungsten and cobalt creates environmental impacts.

Conclusion

Wolframkarbid-Kobalt is a functional material used in a range of sectors, from cutting tools and mining equipment to aerospace components. Despite challenges such as cost and brittleness, its quantifiable properties support its application in environments requiring extended durability. Given that material production outcomes can be measured reliably, tungsten carbide-cobalt is expected to remain a key material for the manufacture of high-performance tools and components.

Stanford Advanced Materials (SAM) has extensive experience in the manufacture and supply of high-quality tungsten carbide-cobalt powder (WC-8Co). The company provides not only tungsten carbide-cobalt but also a range of other advanced materials. It offers customised solutions that extend equipment service life and guarantee reliable performance under demanding applications. For further information, please visit our homepage.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento