Case Study: Versatile Applications Of Tantalum Tubes In Chemical Manufacturing

Introduction

In the chemical industry, various materials and pieces of equipment are used to handle chemicals safely. They are used to process chemicals efficiently. Tantalum tubes are one critical component used in this industry. This article examines the significance of tantalum tubes in chemical production.

[1]

[1]

Figure 1. Chemical Processing

Understanding Tantalum Tubes

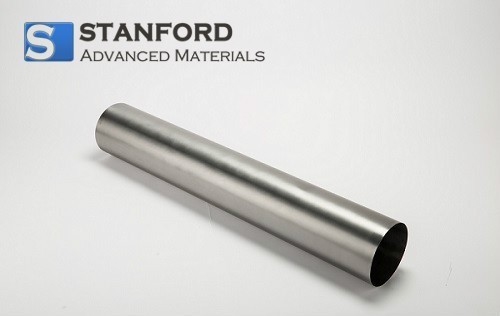

Tantalum tubes are cylindrical structures made from tantalum metal. Tantalum is a rare metal that resists corrosion. They withstand high temperatures. They maintain chemical purity. They are compatible with various chemicals.

Figure 2. Tantalum Tubes

Applications of Tantalum Tubes in the Chemical Industry

Tantalum tubes are used in the chemical industry because they resist corrosion and high temperatures. They have measurable applications in several processes.

1. Corrosion-resistant Equipment: Tantalum tubes are employed in the design of chemical process plants. This includes heat exchangers, condensers and reaction vessels. Their resistance to acids and high temperature conditions permits safe operations.

2. Petrochemical Industry: The tubes are used in heat exchangers and pipeline systems during chemical and petrochemical production and refining. They resist substances such as sulphuric acid and hydrochloric acid. Consequently, they are suited to handling aggressive chemicals.

3. Electrolysis: Tantalum is used as an electrode material in the manufacture of chlor-alkali by electrolysis. Tantalum tubes serve as electrode housings. They operate under aggressive chemical reactions and high temperatures.

4. Pharmaceutical Manufacturing: Tantalum tubes are utilised in processes that involve corrosive chemicals or high-temperature reactions in pharmaceutical production. They help maintain product purity. They meet regulatory standards.

5. Semiconductor Industry: Tantalum tubes are applied in chemical vapour deposition (CVD) and atomic layer deposition (ALD) in semiconductor fabrication. They provide a chemically inert environment required for precise manufacturing.

Conclusion

Tantalum tubes are essential components in chemical manufacturing because they possess specific material properties. They contribute to safe operations in corrosion‐resistant facilities, petrochemical plants, electrolysis, pharmaceutical production and semiconductor fabrication. In future, they are expected to be used in industries that handle corrosive substances and require high purity conditions.

Stanford Advanced Materials (SAM) supplies tantalum tubes and related products from stock at reasonable prices. A wide range of tantalum products is available on the website. Please submit an enquiry if you are interested.

Reference:

[1] Winn, Z. (2021). Accelerating clinical trials through local pharmaceutical production [Photo]. https://news.mit.edu/2021/snapdragon-drug-chemistry-0611

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento