Calcium Copper Titanate Powder: Properties And Applications

Introduction

Calcium Copper Titanate (CCTO) powder with the chemical formula CaCu₃Ti₄O₁₂ is a ceramic material. It exhibits specific electrical behaviour. The material has a high dielectric constant and is under investigation for applications in modern electronics and energy storage. Its high dielectric constant, low dielectric loss and ferrolectric properties allow its use in capacitors, sensors, batteries and additional devices.

This article discusses the properties and applications of CCTO.

Properties of Calcium Copper Titanate Powder

1. High Dielectric Constant

CCTO powder exhibits a high dielectric constant. Measurements at room temperature range from 10 000 to 100 000, depending on synthesis and processing methods. It can store a large quantity of electrical energy, which benefits capacitors that require high capacitance.

Conventional dielectric materials such as Barium Titanate typically measure between 3 000 and 5 000. Consequently, capacitors based on CCTO can achieve reduced dimensions and increased energy density.

2. Low Dielectric Loss

CCTO powder exhibits a low dielectric loss factor, typically below 0.05 at room temperature for frequencies up to 10 MHz. This property is essential for high-frequency applications in telecommunications where energy losses must be minimised.

CCTO capacitors maintain performance in radar systems or high-frequency circuits without generating excessive heat, thereby ensuring stable operation.

3. Ferrolectric and Piezoelectric Properties

CCTO shows ferrolectric behaviour with polarisation values ranging from 0.1 to 0.2 μC/cm² at room temperature. Its ability to retain polarisation permits its use in devices where electrical fields control data states.

The piezoelectric coefficient of CCTO is approximately 2–5 pC/N. This coefficient enables the generation of electrical charges under mechanical stress, thereby allowing its use in vibration sensors and actuators.

4. Multiferroic Behaviour

At room temperature, CCTO exhibits both electrical and magnetic order. Magnetoelectric coupling has been measured at up to 0.01 V/cm-Oe. This permits the simultaneous manipulation of electrical and magnetic states, which is of interest in spintronics and data storage.

5. High-Temperature Stability

CCTO remains thermally stable up to 1 000 °C. It retains its dielectric properties without significant degradation. This stability permits its use in high-temperature environments in automotive and aerospace electronics where other materials may fail.

Conventional ceramics may begin to decompose between 600 and 800 °C, thereby providing an advantage to CCTO in high-load applications.

Synthesis of Calcium Copper Titanate Powder

CCTO powder is typically synthesised by various methods, including solid-state reactions, the sol–gel process and hydrothermal techniques. In the solid-state reaction method, calcium carbonate (CaCO₃), copper oxide (CuO) and titanium dioxide (TiO₂) are mixed and heated at high temperatures. This method is frequently chosen for its simplicity and efficiency.

The sol–gel process allows improved control over particle size and shape. This is advantageous in applications requiring uniform powder properties. In contrast, the hydrothermal method produces high-purity CCTO with excellent crystallinity. Each synthesis method presents specific benefits, depending on the intended application of the material.

Applications of Calcium Copper Titanate Powder

1. High-Capacitance Electronic Components

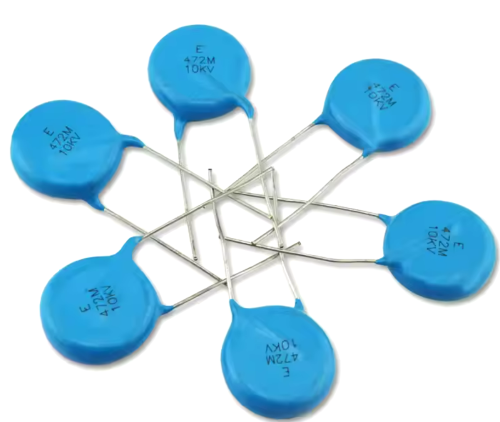

The high dielectric constant of CCTO powder makes it suitable for manufacturing capacitors with high capacitance. Such capacitors are integral in energy storage systems in electronic devices that require high energy density, including smartphones, laptops and electric vehicles.

Capacitors based on CCTO facilitate effective electrical energy storage and discharge, which is critical for energy management in modern electronic systems.

2. Vibration Dampening and Acoustic Sensors

CCTO powder is used in vibration dampening devices due to its piezoelectric properties. In high-frequency electronic devices, its capability to dampen vibrations reduces noise and interference, thereby aiding performance.

The piezoelectric effect in CCTO converts mechanical energy from sound or pressure waves into electrical signals. This function is applied in automotive systems, industrial machinery and medical equipment.

3. Advanced Battery Technologies

The electrochemical characteristics of CCTO powder are under investigation for use in advanced battery technologies. Its high energy density and cycle stability may improve the capacity and lifetime of rechargeable batteries. This is important for electric vehicles and portable electronic devices.

Researchers are exploring the role of CCTO in improving lithium-ion batteries and other systems such as solid-state batteries. The thermal stability of CCTO supports its use in batteries that operate under demanding conditions.

4. Solar Cells

In solar energy applications, CCTO powder may increase both the efficiency and the stability of solar cells. Its high dielectric constant and low loss factor improve energy capture and conversion, thereby enhancing solar cell performance.

5. Aerospace Capacitors

CCTO powder is suitable for aerospace electronics due to its high-temperature stability and mechanical durability. Capacitors manufactured using CCTO are designed to withstand extreme conditions such as high temperatures, vibrations and radiation. This helps to maintain the reliability of electronic systems in aircraft and spacecraft.

Conclusion

Calcium Copper Titanate Powder is employed in applications requiring specific dielectric properties. Its use spans from high-capacitance capacitors to piezoelectric sensors, advanced batteries and solar cells. The combination of its electrical, thermal and magnetic characteristics supports its application in demanding environments, including aerospace.

Stanford Advanced Materials (SAM) offers Calcium Copper Titanate Powder at competitive prices. Stanford Advanced Materials (SAM) has extensive experience in supplying ceramic dielectric materials. Please submit an enquiry if you are interested.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento